Water heater with heating-supply from transcritical carbon dioxide heat-pump

A carbon dioxide, transcritical technology, applied in hot water central heating systems, household heating, heating methods, etc., can solve the problems of water temperature limitation, low heat pump energy efficiency ratio, destruction of ozone layer greenhouse benefits, etc., to improve efficiency and EER. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

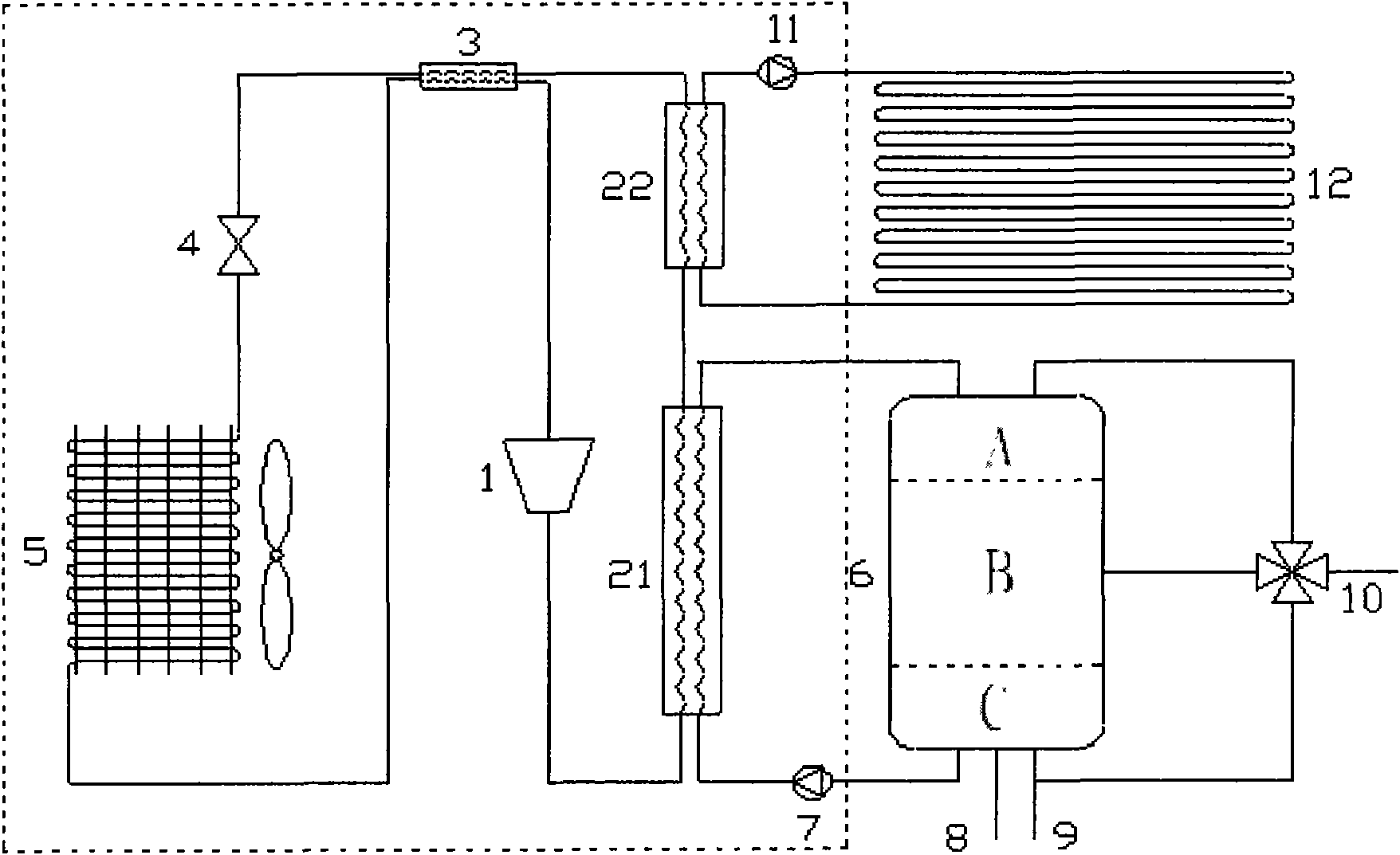

[0021] Attached below figure 1 The present invention is further described.

[0022] Such as figure 1 As shown, a transcritical carbon dioxide heat pump heating water heater includes three parts: a transcritical carbon dioxide heat pump system, a hot water supply system and a heating circulation system.

[0023] Wherein, the transcritical carbon dioxide heat pump system absorbs heat from the outside and provides it to the hot water supply system and the heating system, which includes a compressor 1, a first air cooler 21, and a second air cooler 22 sequentially located on the first circulation pipeline , regenerator 3, expansion valve 4, evaporator 5, regenerator 3;

[0024] Among them, the heat exchangers of the first air cooler 21 and the second air cooler 22 adopt the shell-and-tube type, and the evaporator 3 adopts a plate-fin heat exchanger, and the heat exchange of the evaporator 5 is enhanced by a fan;

[0025] The working fluid used in the transcritical carbon dioxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com