Mounting method for insulating layer of nuclear reactor pressure vessel

A technology for pressure vessels and nuclear reactors, applied in reactors, nuclear engineering, nuclear power generation, etc., can solve the problems of increased unsafe probability, affecting the completion time of pressure vessel installation, and long time, so as to reduce the probability of accidents and avoid long-term Time to run multiple heavy loads to reduce the effect of bruises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

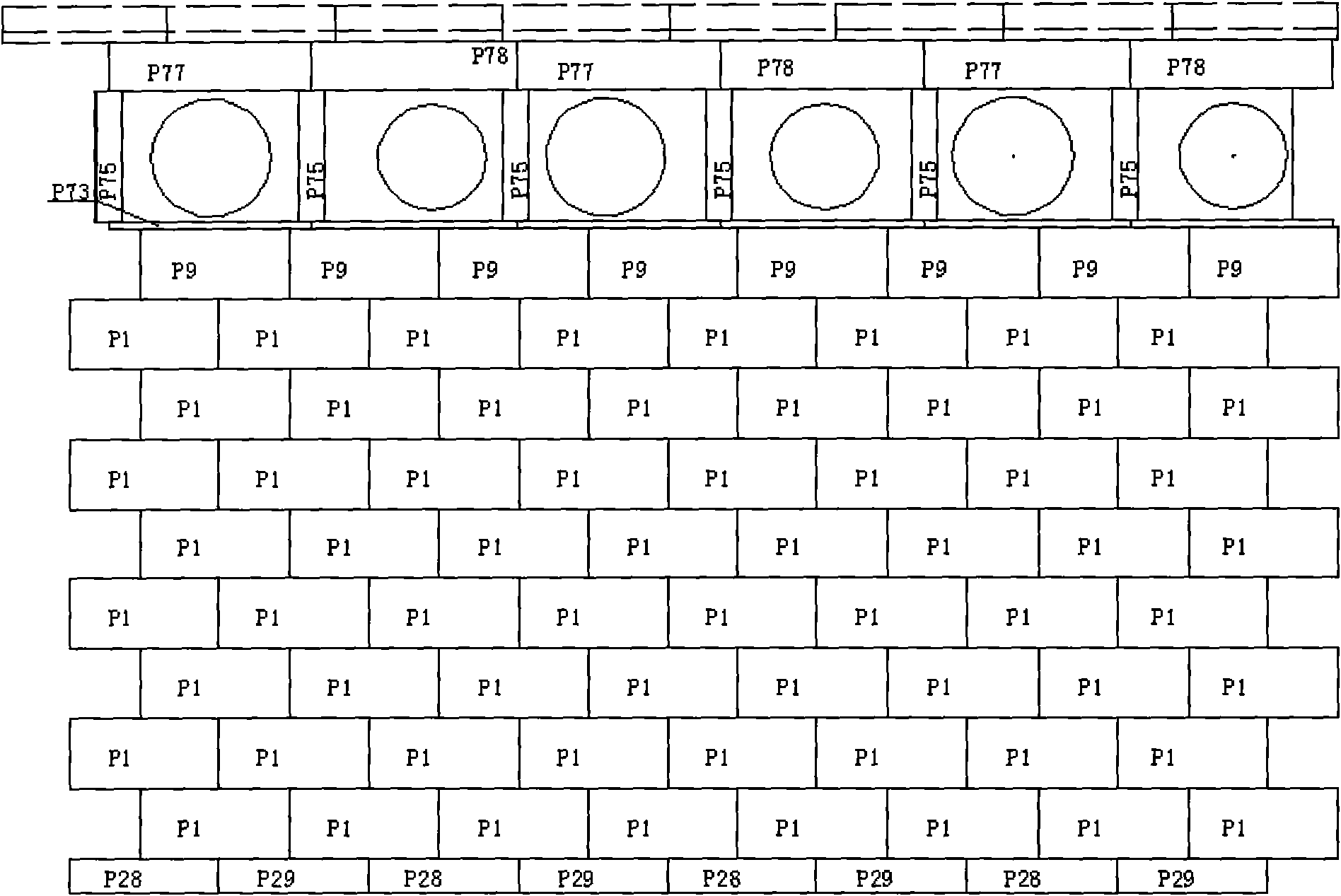

[0046] 1. On-site assembly of the cylinder insulation layer

[0047] The improvement that the present invention relates to is the insulation layer of the cylinder body, and the main scope of on-site assembly is all other parts in the insulation layer of the cylinder body except the support ring P71 / 72 and the flange edge insulation board P77 / 78.

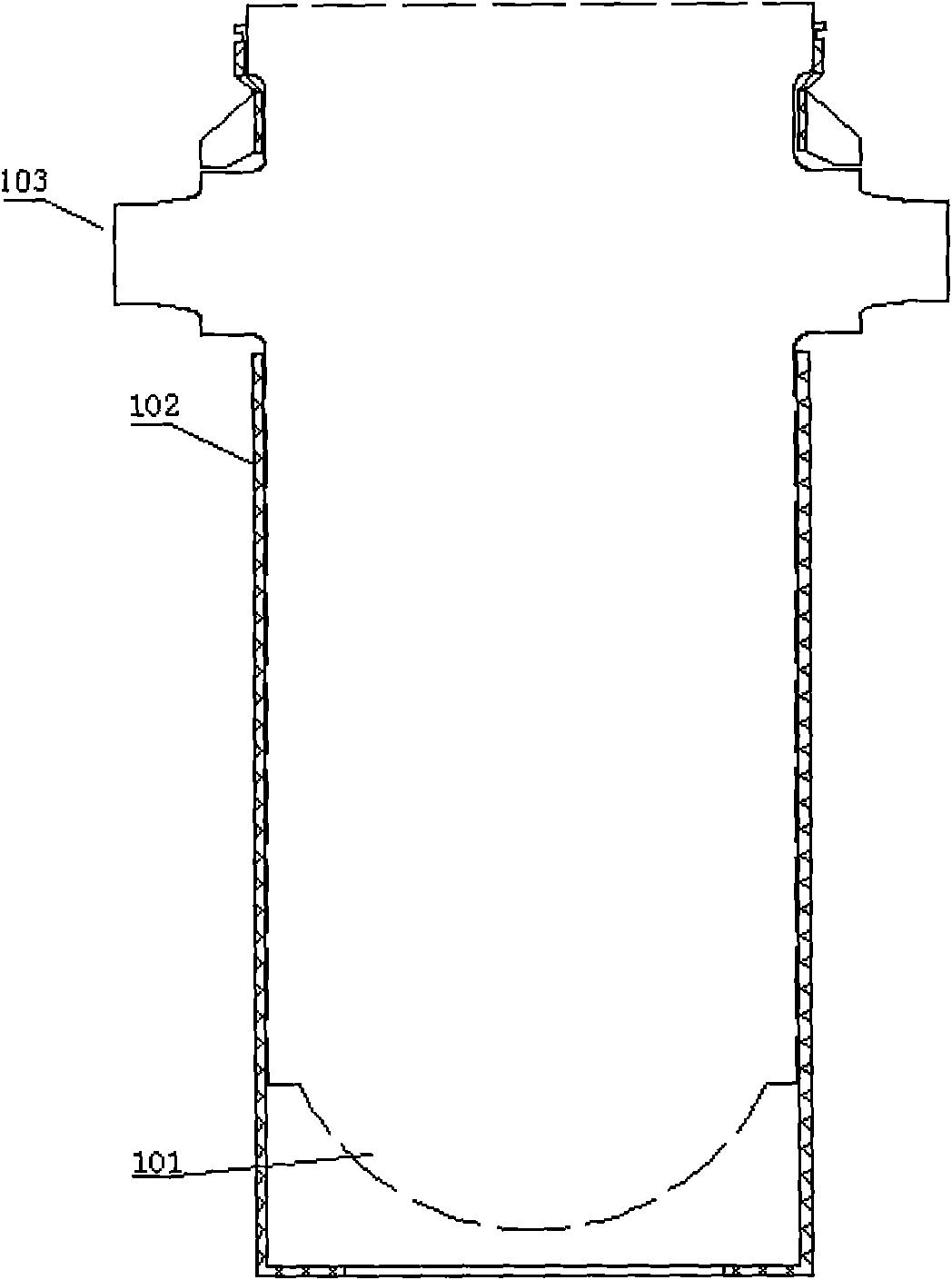

[0048] In this embodiment, the outer diameter of the pressure vessel 101 immediately below the coolant nozzle 103 does not exceed Φ4435mm. Since the gap between the inner wall of the insulation layer and the outer wall of the pressure vessel is 18.5mm, the inner diameter of the connecting ring P73 / 74 is 4435+18.5+18.5=Φ4472mm.

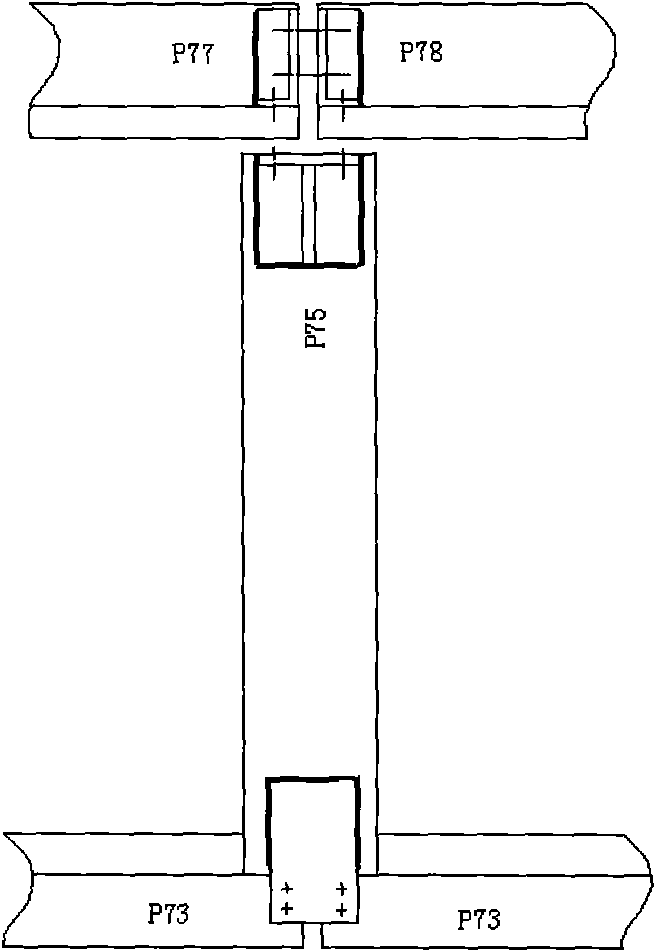

[0049] In order to maintain the roundness and rigidity of the connecting ring P73 / 74, a grooved steel ring is prefabricated during specific implementation. Such as Figure 4 As shown, the channel steel ring 104 is formed by connecting three segments of arc steel materials, and the three are connected by bolts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com