Material distributing machine

A distributing machine and distributing box technology, which is applied to the parts of fuel cells, electrical components, battery electrodes, etc., can solve the problems of low production efficiency, uneven distribution of powder, and non-continuous production, so as to achieve uniform distribution of powder, The effect of continuous production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

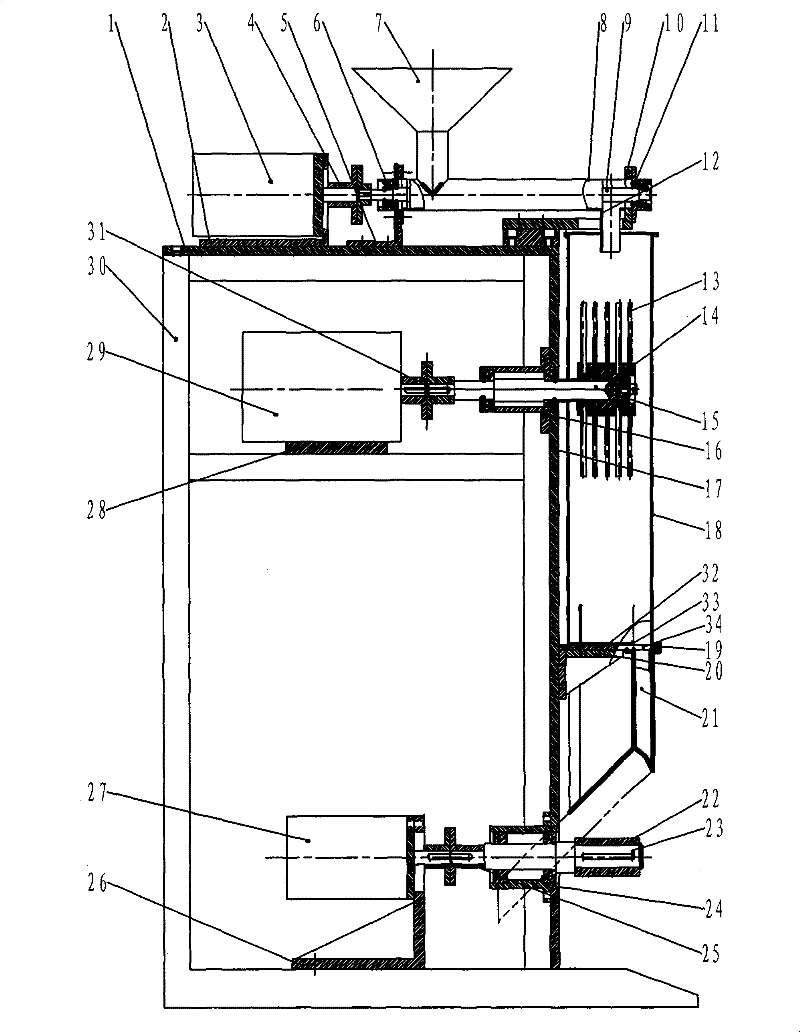

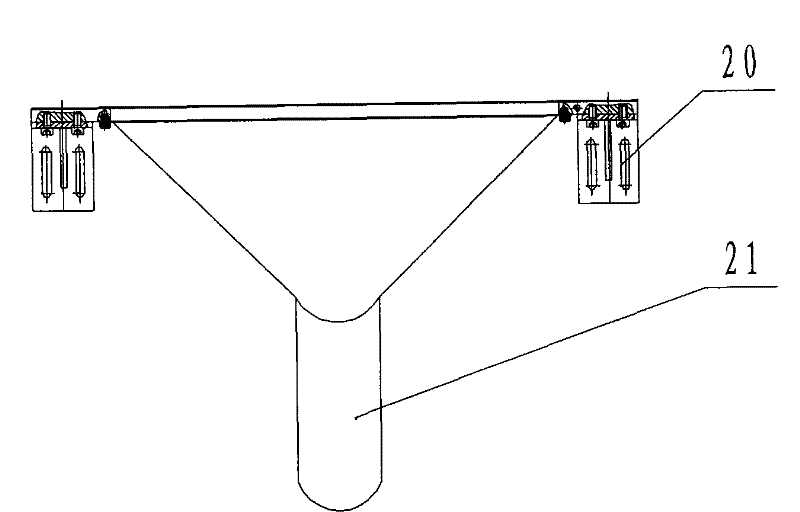

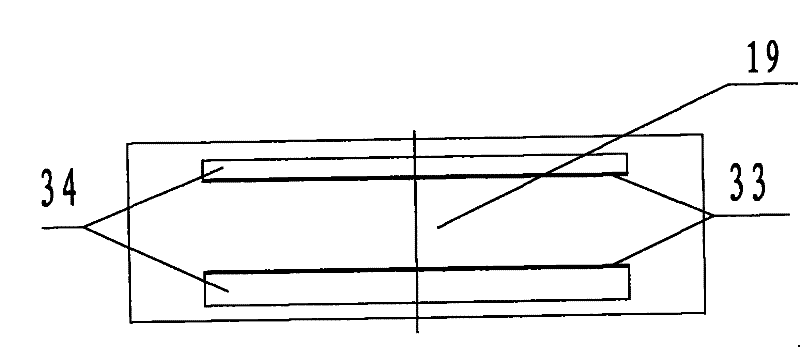

[0012] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof.

[0013] The cloth machine designed by the present invention (see Figure 1-3 ), which is used for the dry-embedding manufacturing process of the air electrode of the zinc-air battery (hereinafter referred to as the pole piece), including four parts of the quantitative feeding mechanism, the throwing mechanism, the nickel mesh transmission mechanism and the material recovery box installed on the frame 30, and its characteristics The quantitative feeding mechanism includes a hopper 7, a screw feeding main shaft 9 and its casing 8, and a feeding servo motor 3; Side; the screw feeding spindle 9 and its shell 8 are installed on the No. 1 feeding mechanism bracket 5 and the No. 2 feeding mechanism bracket 11, and the No. 1 feeding mechanism bracket 5 and the No. 2 feeding mechanism bracket 11 are fixed on the frame 30 through the upper support plate 1 The other side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com