Rotor sheet of single pivot electric generator with electric frequency raising

A technology for rotor punching and generators, which is applied to asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of poor power generation quality, small starting torque, and large speed fluctuations of intermediate frequency generators, and achieve improved capacity and asynchronous The effect of large starting torque and small speed fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

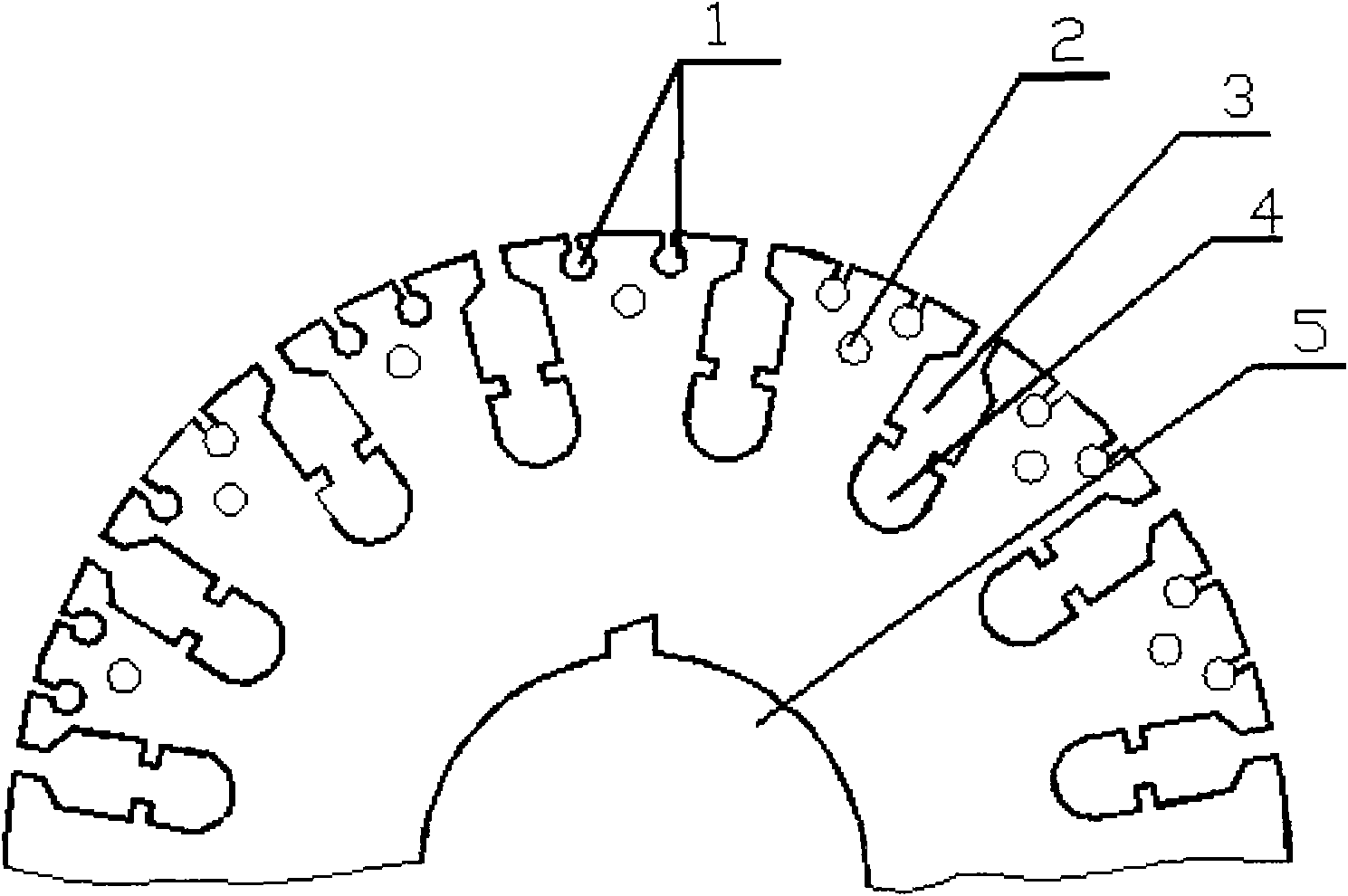

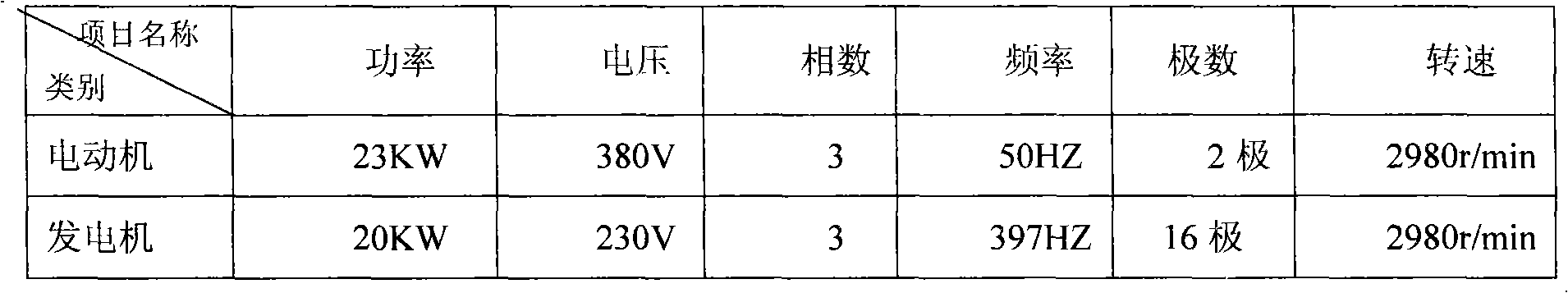

[0008] Such as figure 1 As shown, in order to be more clear, it will be further explained in conjunction with specific embodiments, a single-pivot electric up-frequency generator, its power frequency (50HZ) 2-pole asynchronous motor and intermediate frequency (397HZ) 16-pole synchronous generator common rotor iron core The rotor punching diagram is attached.

[0009] Insert 32 brass round rods into 32 small round holes 1, 16 round copper rods into 16 small round holes 2, and 16 rectangular red copper rods into 16 shovel-shaped slots 4. These conductors are firmly welded to the copper plates at both ends of the rotor core to form a three-layer squirrel cage. When the asynchronous motor is started, the resistance is required to be relatively large. At this time, the squirrel cages in the 32 small round holes 1 are made of brass, and the resistivity Larger, so the resistance is larger, and the copper rods (rods) of the other 16 small round holes 2 and 16 shovel-shaped grooves 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com