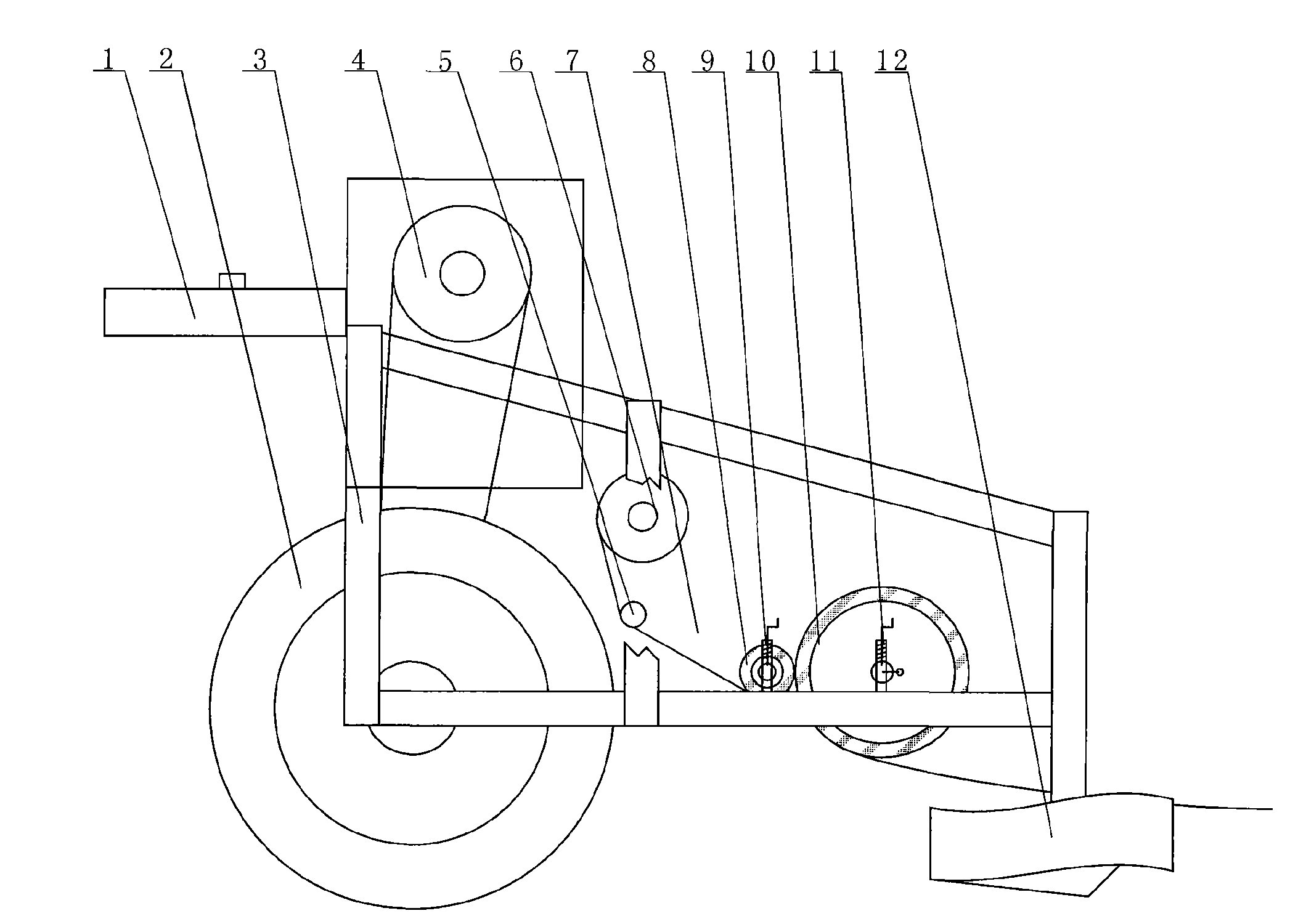

Power plastic mulching machine

A technology of mulch covering and power, which is applied in the direction of plant protection covers, etc., can solve the problems of high work intensity, low labor efficiency, and high price, and achieve the effects of reducing labor intensity, convenient operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

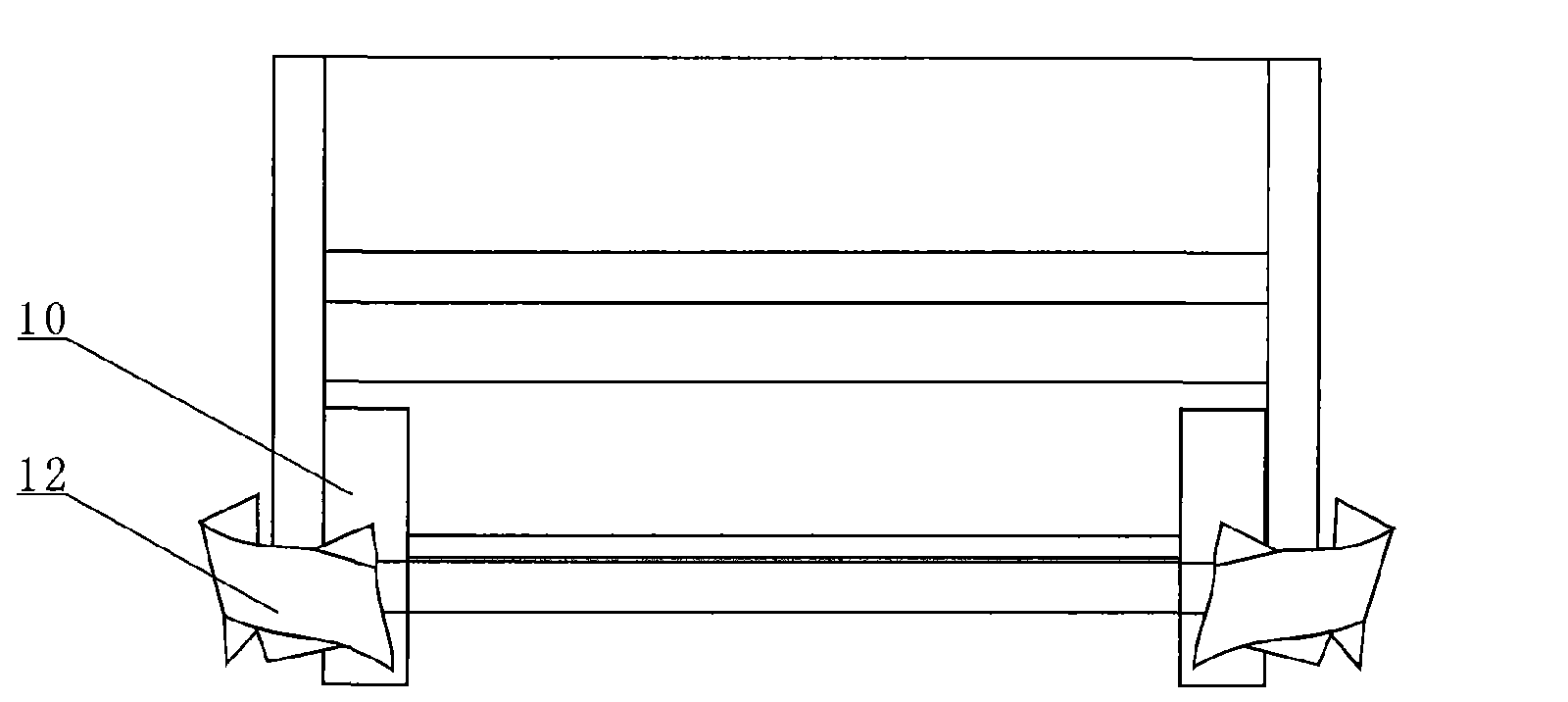

[0029] The motor uses a battery as the power supply, and the motor is connected to the traveling wheel 2 through a belt transmission mechanism. A roll of plastic film is installed on the plastic film roller 6, and the plastic film bypasses the tension roller 5 and enters under the pressure film roller 8. The plastic film obtains a resistance, so that the light and thin plastic film can be spread out during the covering process, and the appropriate resistance can also ensure that the plastic film will not be torn. When it is put on, the mulch film will not be crushed. The height of laminating roller 8 can be adjusted by adjusting the vertical centering mechanism 9, so as to be suitable for working surfaces of different heights. Can adjust the height of two laminating wheels 10 by adjusting the horizontal and vertical centering mechanism 11, generally speaking, the height of the lower edge of the embossing wheels 10 is lower than the height of the lower edge of the laminating ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com