Method for preparing active floridin through microwave activation

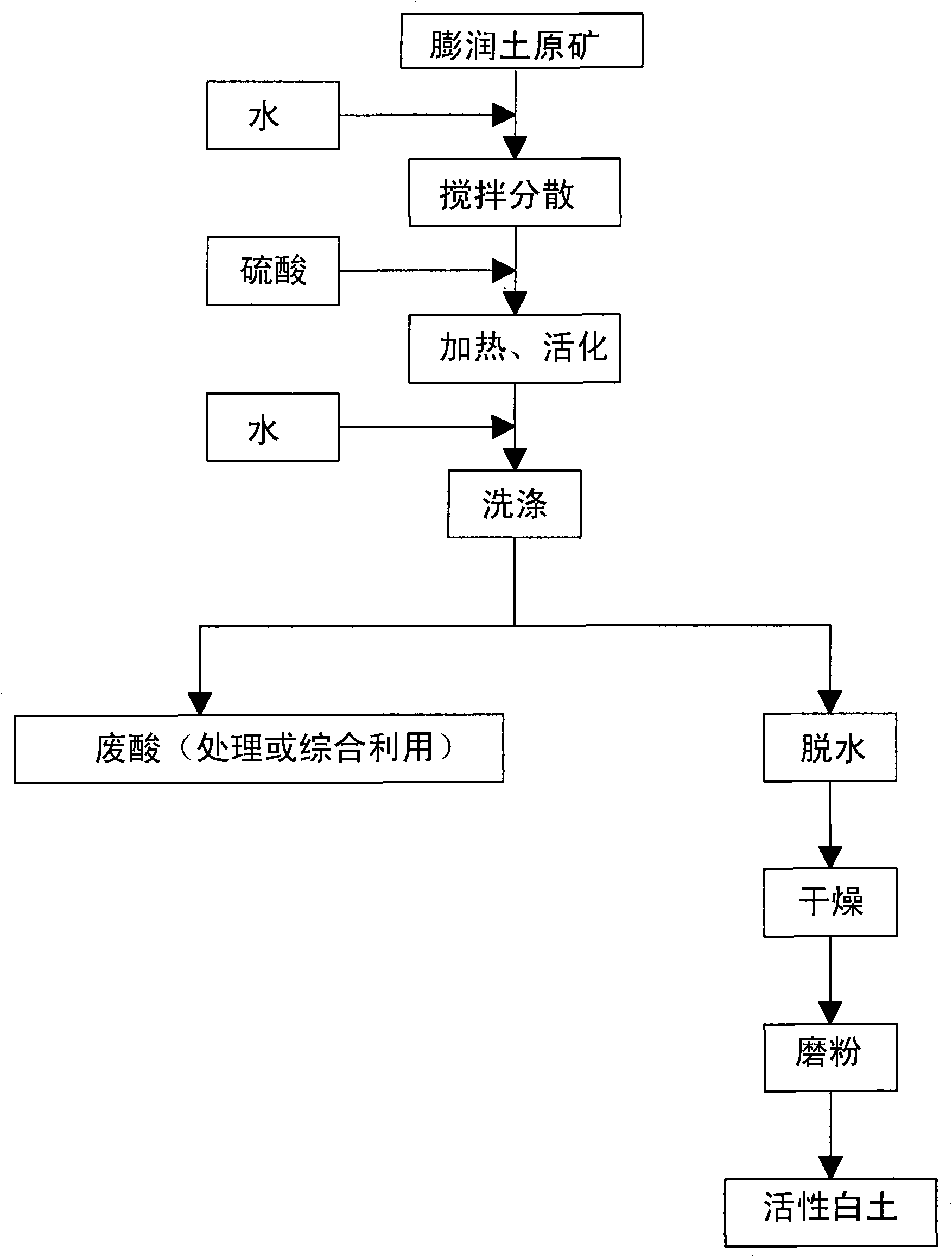

A technology of activated clay and microwave activation, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of excessive washing water, large amount of sulfuric acid, and long activation reaction time, so as to increase retention and improve activation effect , the effect of easy automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

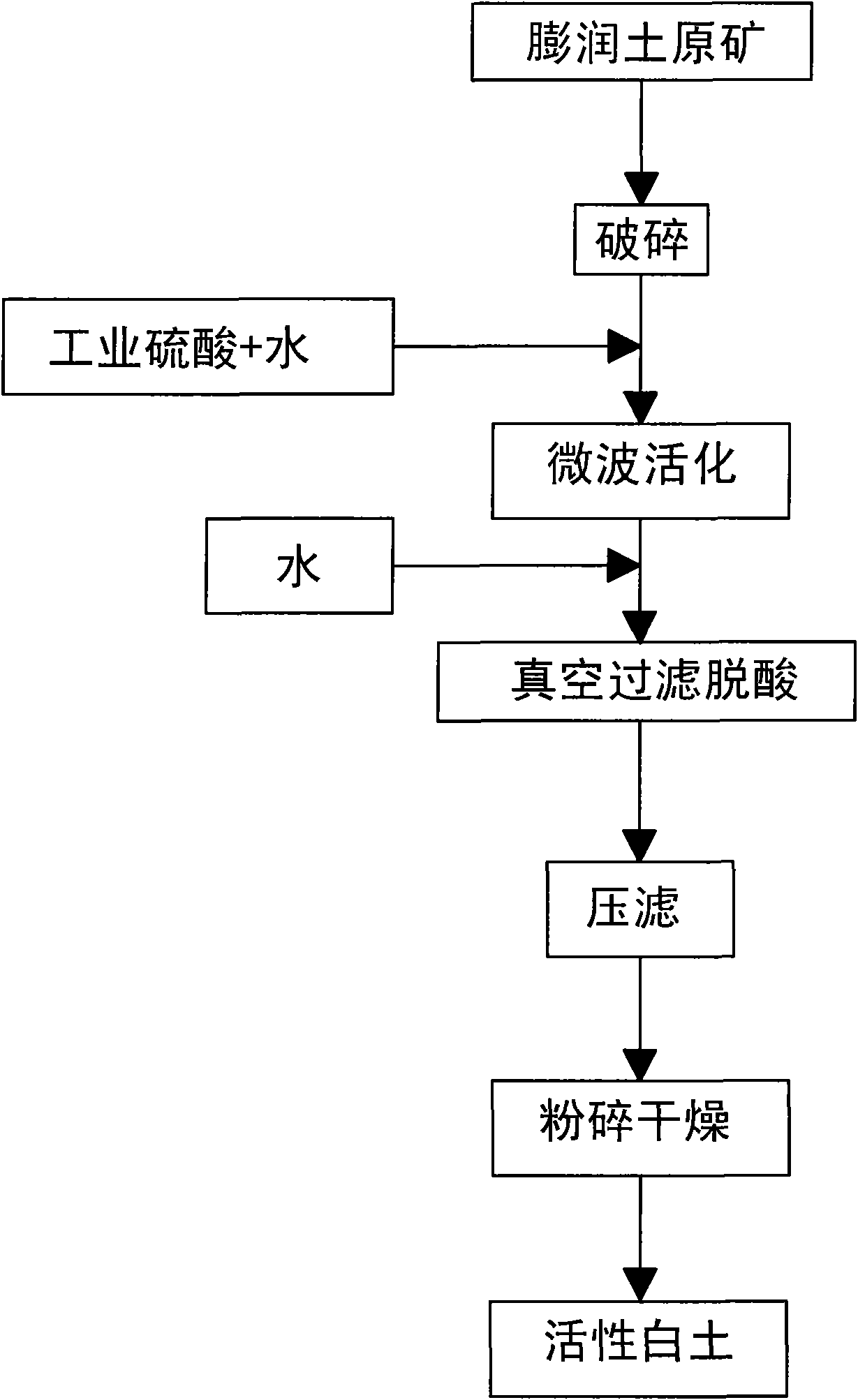

[0021] Embodiment: a kind of microwave activation prepares the method for active clay, is made up of following steps successively:

[0022] The process is attached figure 2 Shown:

[0023] The first step: use calcium-based bentonite raw ore from Anhui Province to prepare activated clay. The raw calcium-based bentonite ore is crushed by a 300×150 pair of roller crushers. After crushing, the particle size of the material is ≤5mm to obtain bentonite raw materials;

[0024] The second step: the bentonite raw material obtained in the first step is added to the screw mixer through a quantitative feeder, and the bentonite raw material and industrial sulfuric acid are mixed evenly through the strong stirring of the screw mixer to obtain a bentonite slurry. The bentonite raw material in the slurry is The mass concentration accounting for the whole slurry is 65%, and the consumption of the sulfuric acid is: 150 kilograms of sulfuric acid is used for every ton of bentonite raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com