Coal supply tamping device of side-mounted coke oven

A technology for coke oven and coal feeding, which is applied in the fields of coal feeding and tamping devices, can solve the problems of high labor intensity, and achieve the effects of reducing labor intensity, improving production efficiency, and improving the quality of coal cakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

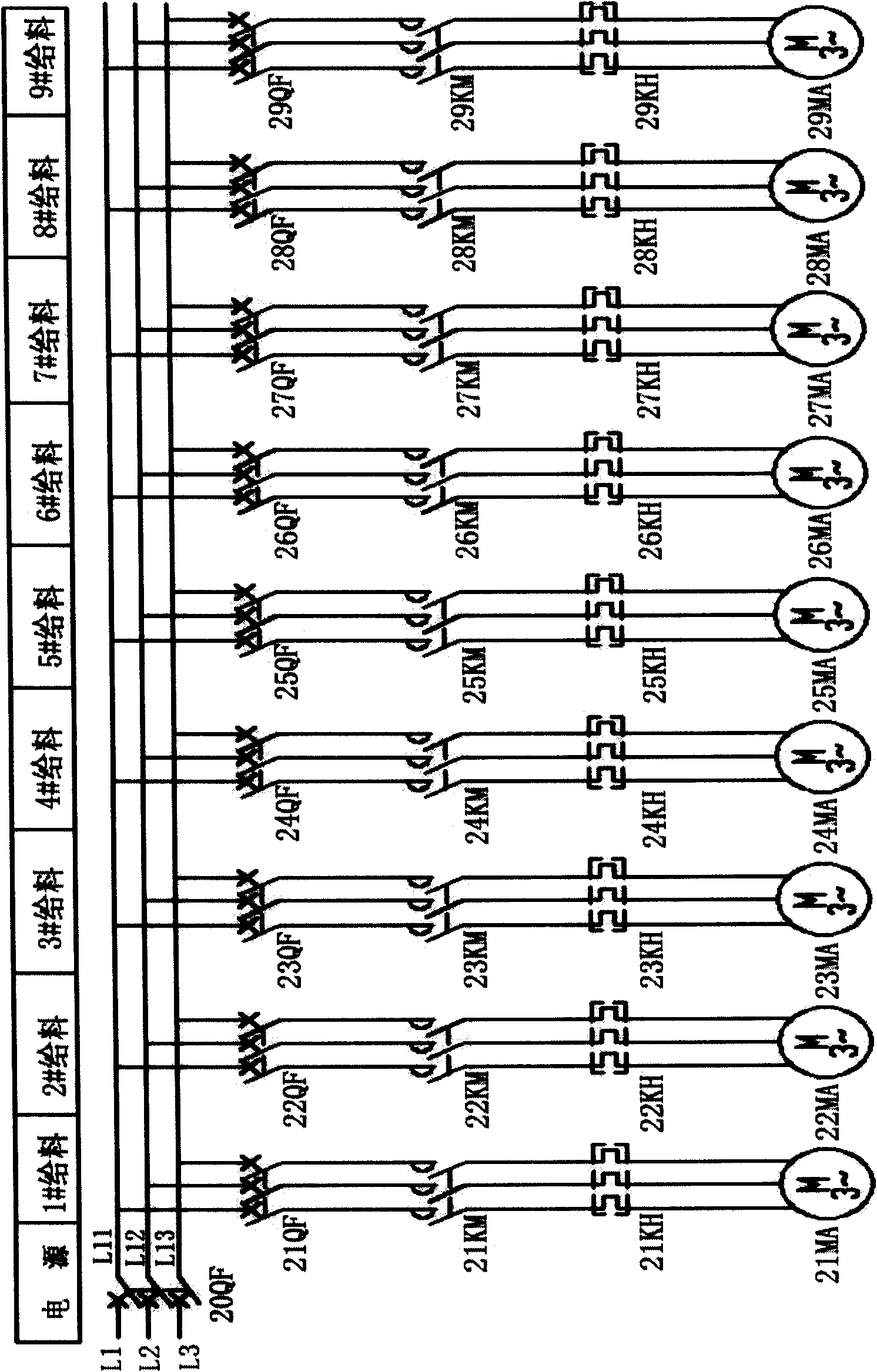

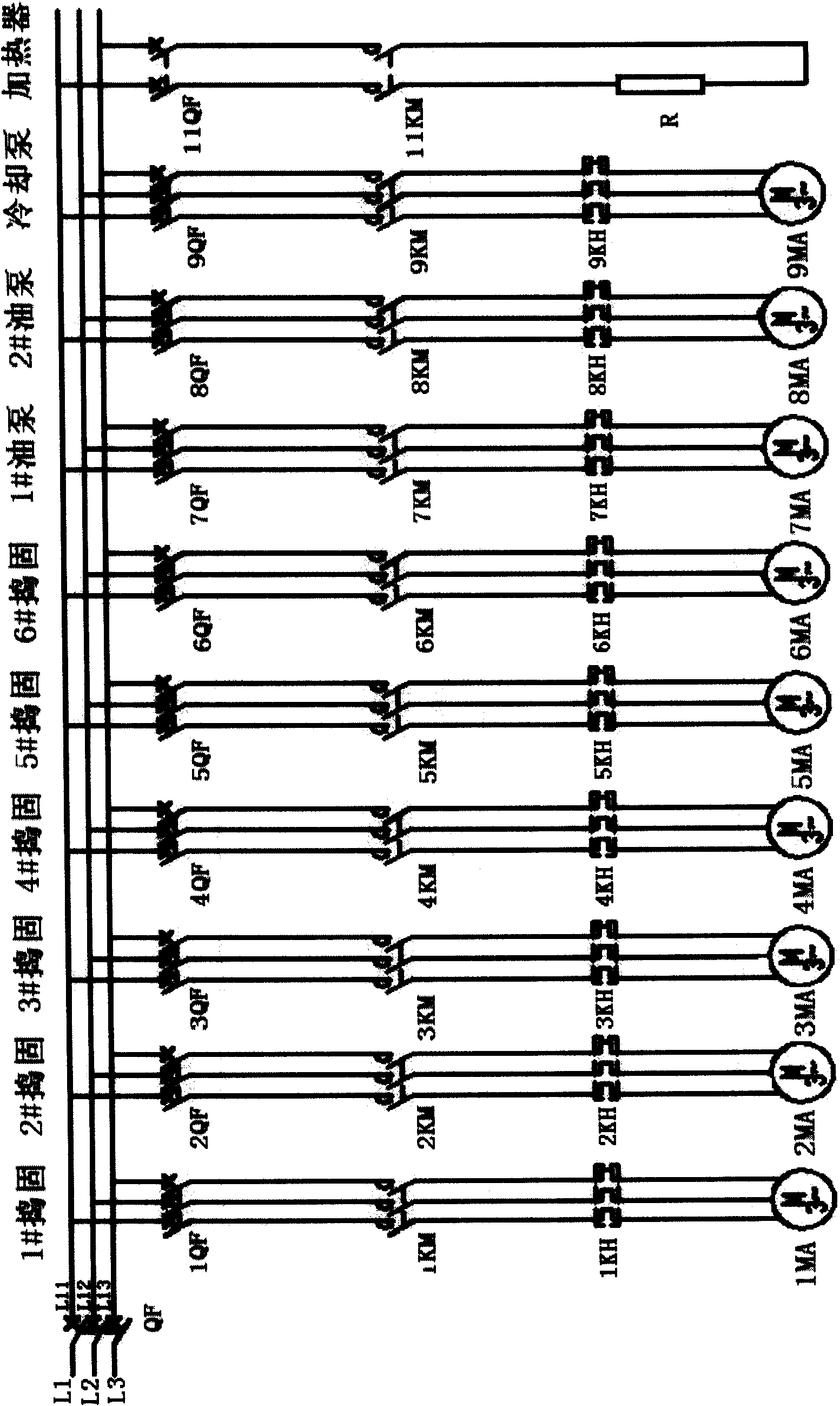

[0009] As shown in the attached figure, the coal discharge circuit is composed of switches 20QF~29QF, contactors 21KM~29KM, relays 21KH~29KH and motors 21MA~29MA. Switches 21QF, contactors 21KM and relays 21KH are connected in parallel with motor 21MA after being connected in series, and switches 22QF , contactor 22KM, relay 22KH are connected in parallel with motor 22MA after being connected in series, and so on, each branch is connected in parallel with switch 20QF and then connected with three power supplies; tamping circuit switch QF, 1QF~9QF, 11QF, contactor 1KM~9KM, 11KM, Relay 1KH~9KH, motor 1MA~9MA and resistance R, switch 1QF, contactor 1KM, relay 1KH are connected in parallel with motor 1MA after series connection, switch 2QF, contactor 2KM, relay 2KH are connected in series and motor 2MA in parallel, and so on, switch 11QF, contactor 11KM and resistance R ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com