Oil and gas separating system embedded in valve chamber cover

A separation system and valve chamber technology, applied in the field of oil and gas separation systems, can solve problems such as insufficient oil and gas separation, and achieve the effects of low cost and small layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

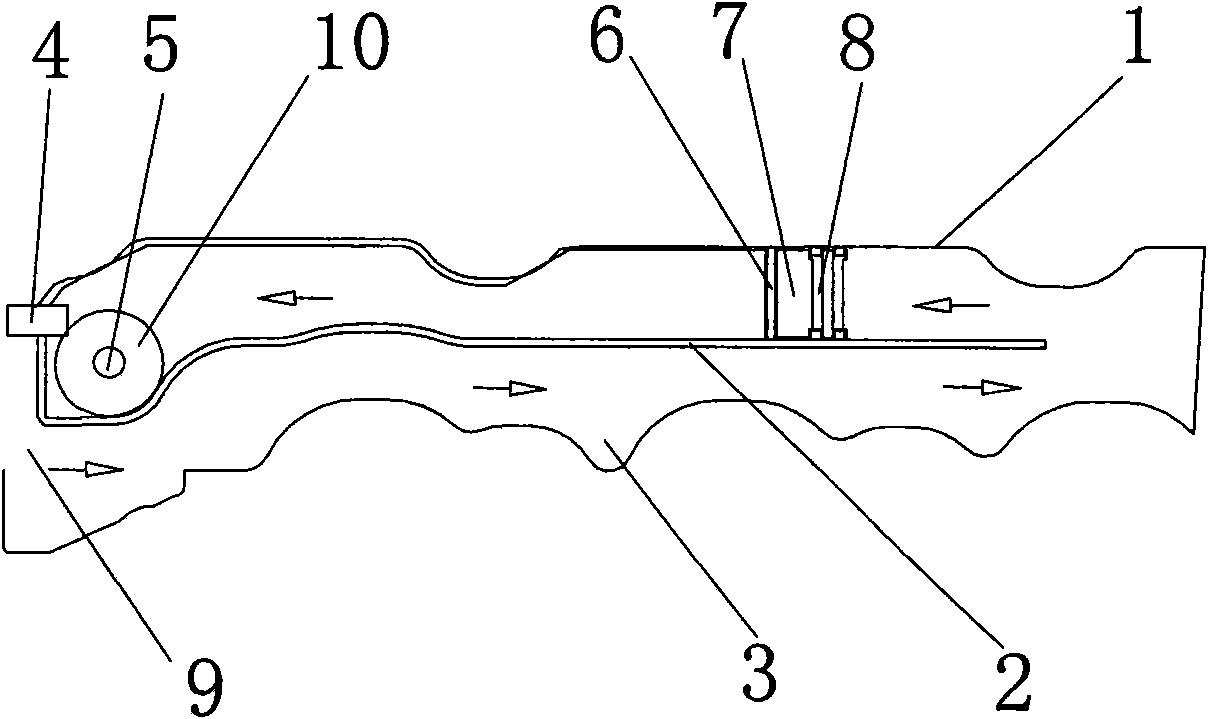

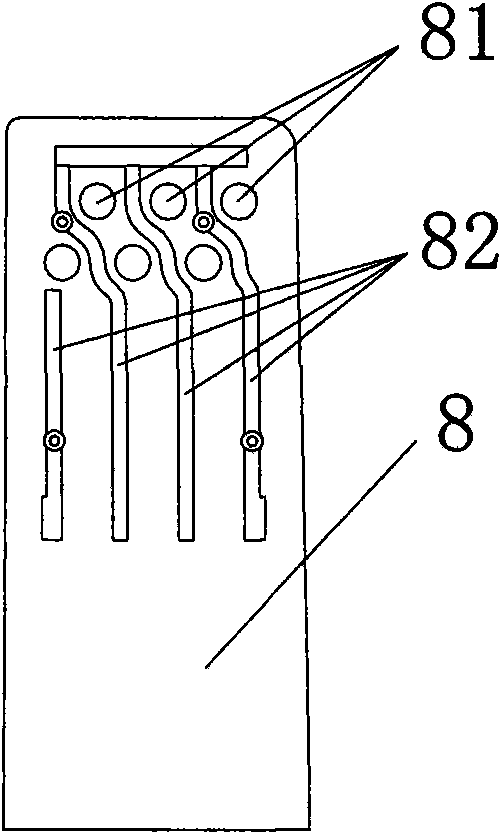

[0013] Example 1, such as figure 1 , 2 As shown in , 3, an oil-gas separation system built in the valve chamber cover, the oil-gas passage structure is divided into upper and lower layers by the partition plate 2 in the housing 1, and the lower layer includes the oil-gas inlet 9 and the labyrinth 3 for pre-separated oil and gas , the upper layer includes the filter unit for the main separation of oil and gas and the oil and gas outlet 4. The filter unit includes a filter plate 8 and a filter 7 arranged in sequence. The filter 7 is mainly composed of sponge-like or wool brush-like items, and is installed behind the filter plate 8. Behind the filter is a baffle that can pass oil and gas. Plate 6 is fixed. The filter plate 8 is provided with a group of oil and gas filter holes 81 and a group of impact plates 82 for oil return collection.

Embodiment 2

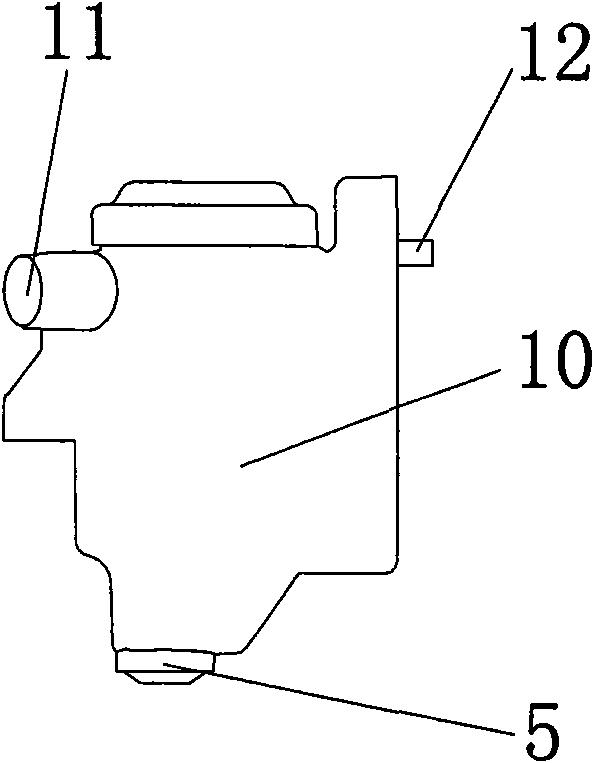

[0014] In Embodiment 2, in order to further separate oil and gas, a PCV valve 10 is provided behind the filter unit for the main separation of oil and gas. All the other are with embodiment 1. The PCV valve 10 includes an oil and gas inlet 12 , an oil and gas outlet 11 and an oil return port 5 .

[0015] The structure of the PCV valve is a one-way valve type, and the control pressure range is -3 ~ 1Kpa; the filter is a filter device similar to sponge or wool brush; the specific structure of the filter plate is to set the filter The impact plate of the hole is formed, the thickness of the impact plate is 1-4mm, and the diameter range of the filter hole is 1.5-5mm.

[0016] The working process of the present invention is, as figure 1 As shown, the oil and gas mixture enters the labyrinth for pre-separation from the oil and gas inlet, and then passes through the filter unit composed of filter plates and filters for main separation. The entire oil and gas separation system adopt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com