Water pump control method and water pump control system in rail vehicle water supply system

A technology for water supply systems and rail vehicles, applied in the field of water pump control methods and control systems, to achieve the effect of preventing leakage problems and improving winter antifreeze ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

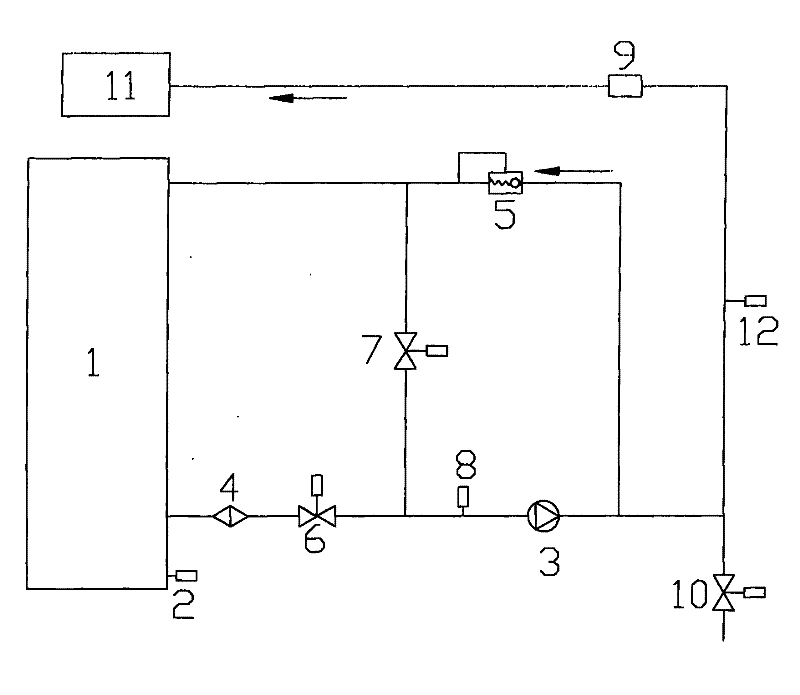

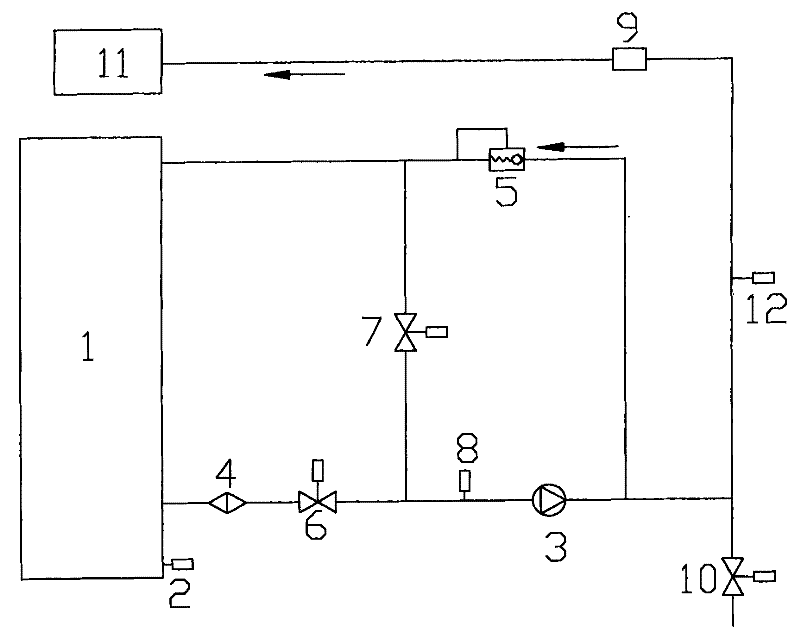

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0024] Such as figure 1 As shown, the water pump control system in the rail vehicle water supply system of the present invention includes: a water tank 1, a water pump 3 for supplying water to the vehicle is set in the water supply pipeline, and a water pump 3 is set at the water outlet of the water tank 1 The filter 4 is used for filtering and cleaning the water entering the water pump 3 .

[0025] A liquid level switch 2 is provided at the position near the bottom of the water tank 1, and a water sensor switch 8 is also provided on the water supply pipeline between the water outlet of the water tank 1 and the water pump 3. The liquid level switch 2 is used to detect water in the water tank 1. Liquid level, the water sensor switch 8 is used to detect whether there is water flowing in the water supply pipeline, whether there is no water in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com