Overvoltage sensor of overhead transmission line

A technology for overhead transmission lines and voltage sensors, which is applied in the direction of measuring current/voltage, voltage dividers, instruments, etc., can solve problems such as inability to reflect the overvoltage characteristics of overhead transmission lines, large differences in amplitude and waveform, and poor operating conditions. Achieve the effect of light weight, stable partial pressure ratio and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

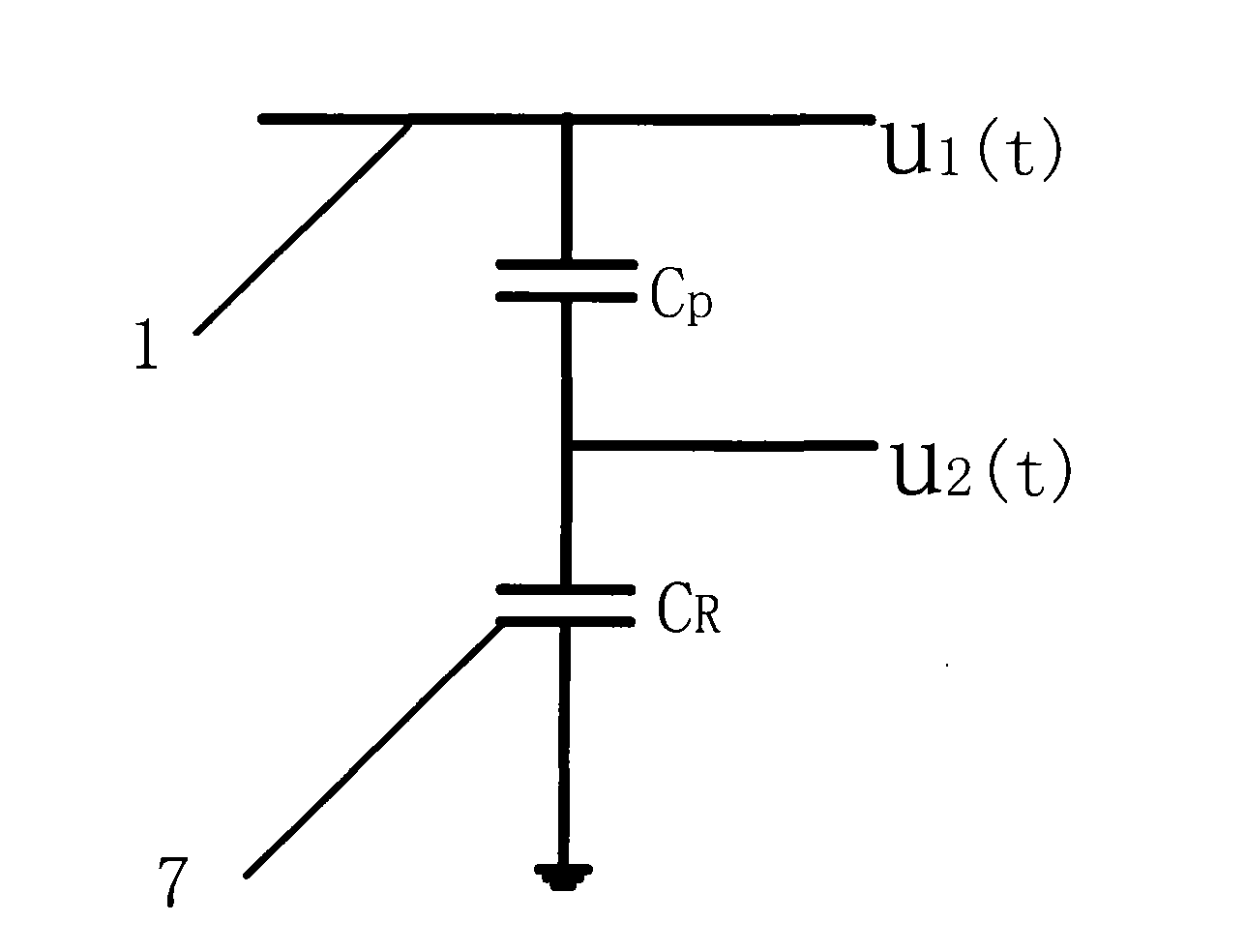

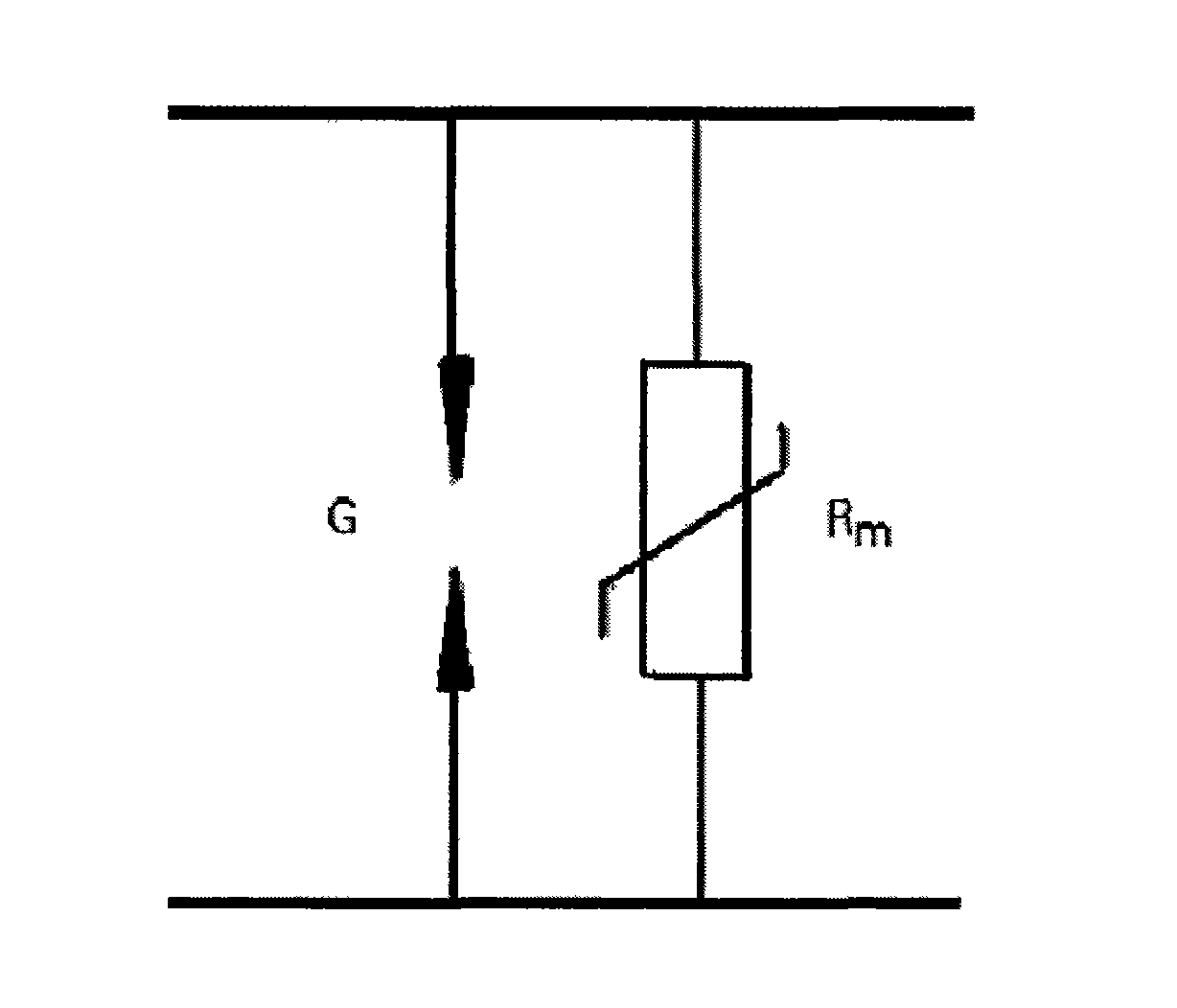

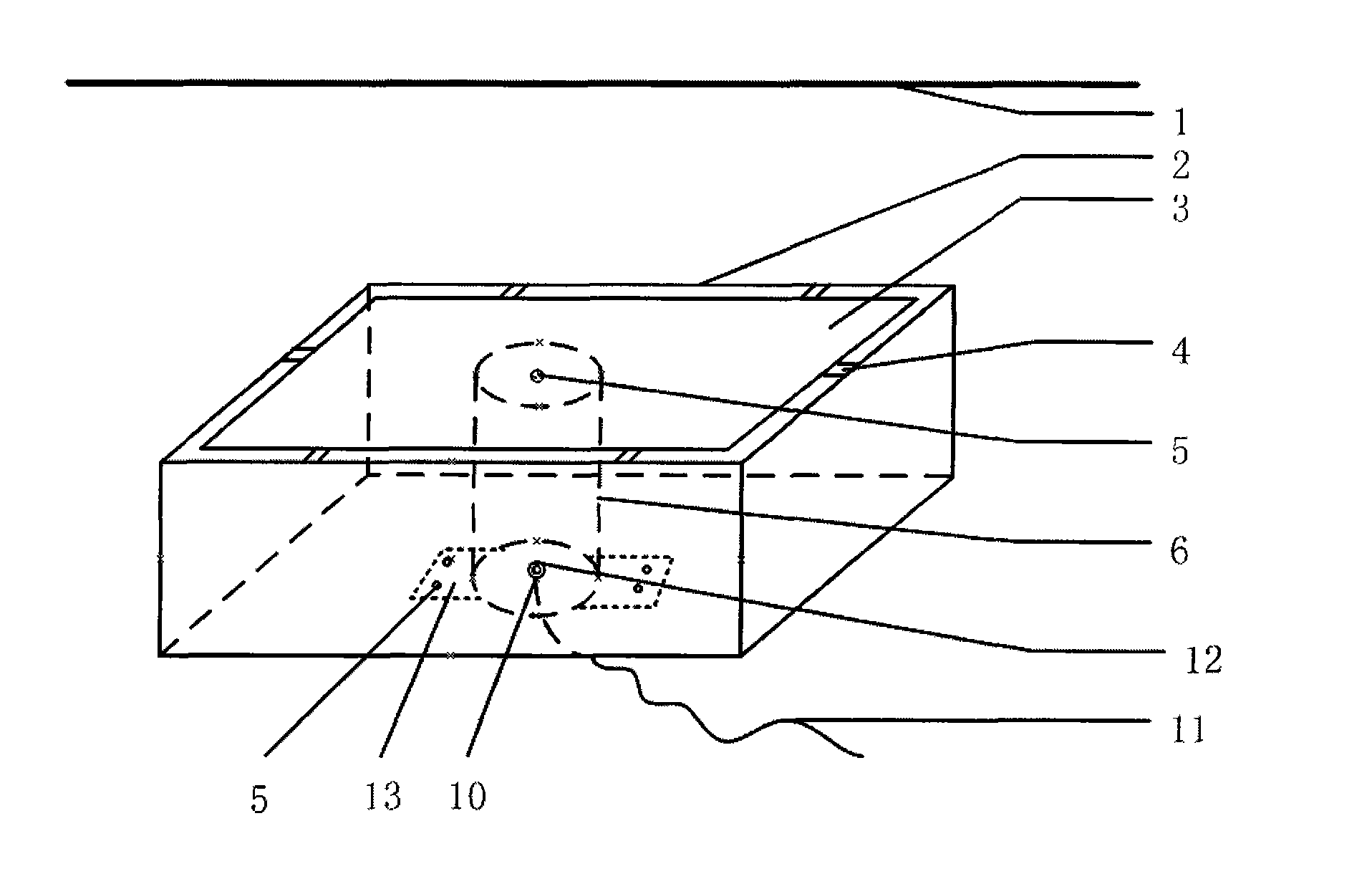

[0030] Such as Figure 1~3 Shown: a 110kV overhead transmission line overvoltage sensor, composed of a voltage monitoring unit and a data acquisition unit. The characteristics are: its voltage monitoring unit includes overhead transmission line 1, shielding shell 2, induction metal plate 3, insulating support 4, voltage dividing capacitor 7, matching resistor 8, front-end protection circuit board 9, stainless steel shielding box 6, coaxial cable 11 . The shielding case 2 is set under the overhead transmission line 1, and is fixed on the tower by bolts 5 and nuts. The distance between the shielding case 2 and the overhead power transmission line 1 is 3000 mm. The material of the shielding case 2 is stainless steel plate, and its thickness The shape of the shielding shell 2 is a cuboid shell with an open upper end, the length of the cuboid shell is 220 mm, the width is 70 mm, and the height is 50 mm. The upper end of the shielding shell 2 is fixed by bolts 5 and nuts. There ar...

Embodiment 2

[0032] A 110kV overhead transmission line overvoltage sensor, the same as embodiment 1, characterized in that: the distance between the shielding case 2 and the overhead transmission line 1 is 8000 mm, the material of the shielding case 2 is an aluminum alloy plate with a thickness of 2.5 mm, the shielding The shape of the shell 2 is a cuboid shell with an open upper end. The length of the cuboid shell is 1520mm, the width is 820mm, and the height is 80mm. The induction metal plate 3 is a rectangle with a thickness of 2.5 mm, and its material is an aluminum alloy plate with a length of 1500 mm and a width of 800 mm.

Embodiment 3

[0034] A 110kV overhead transmission line overvoltage sensor, the same as embodiment 1, characterized in that: the distance between the shielding case 2 and the overhead transmission line 1 is 15000mm, the material of the shielding case 2 is iron plate, and its thickness is 5mm, the shielding case 2 The shape is a cuboid shell with an open upper end. The length of the cuboid shell is 3020mm, the width is 2020mm, and the height is 100mm. The induction metal plate 3 is a rectangle with a thickness of 5 mm, and its material is an iron plate with a length of 3000 mm and a width of 2000 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com