Novel electric motor

A motor, a new type of technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of complex double-layer internal meshing structure, large axial size, low applicable power, etc. Ease of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

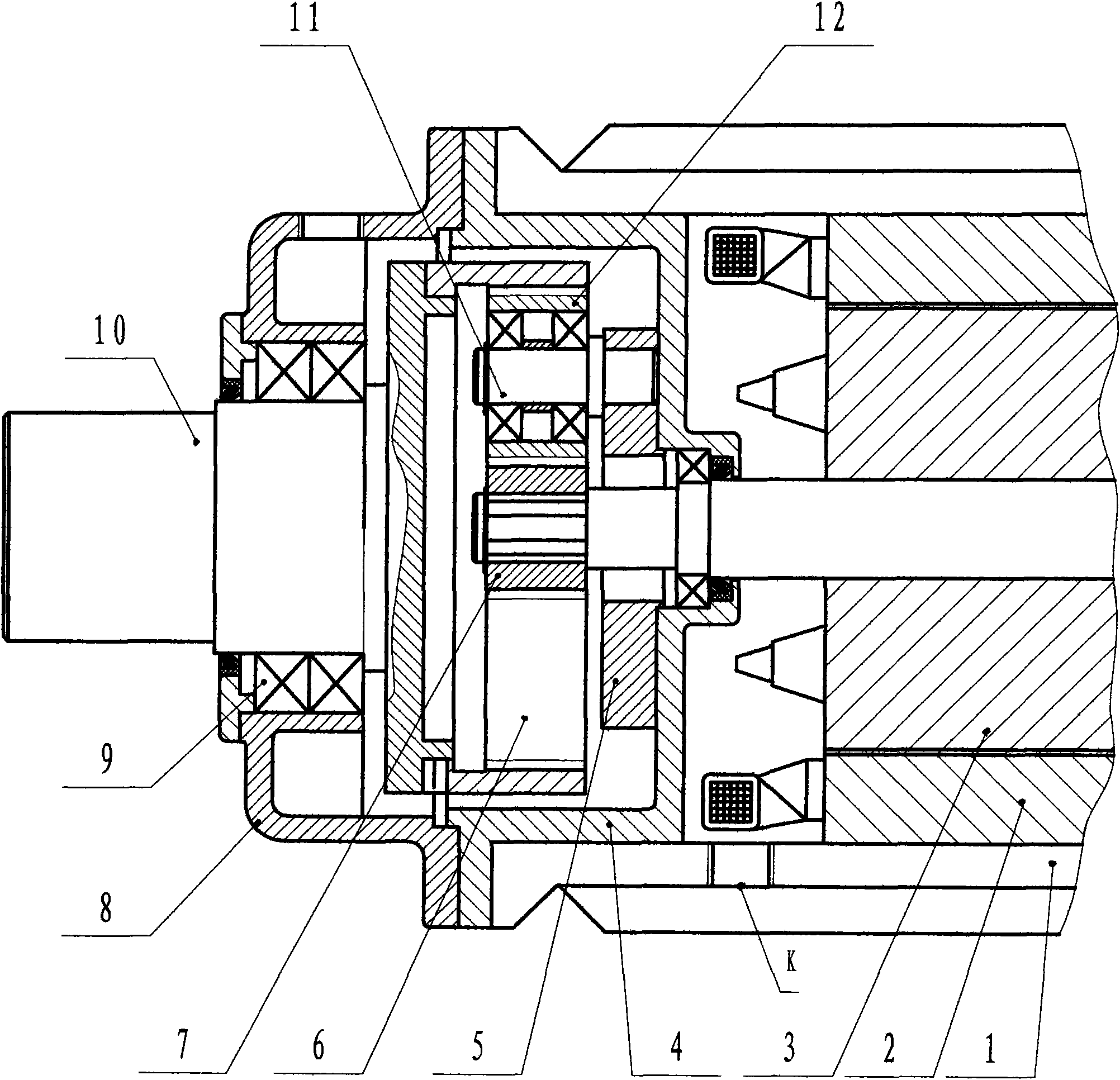

[0016] Such as figure 1 Shown, a kind of novel electric motor comprises motor support (1), big end cover (8) and bearing (9) supporting output shaft (10) in the inner hole, electromagnetic driving part and quasi-planetary transmission part, wherein: electromagnetic The driving part consists of a stator (2) and a rotor (3); the quasi-planetary transmission part consists of a planetary carrier (5), an internal gear (6), a sun gear (7), evenly distributed planetary gears (12) and a planetary gear shaft (11 ), wherein: the sun gear (7) is connected to the rotor shaft (3), the inner gear (6) is connected to the output shaft (10) disc, the planetary gear is supported on the planetary gear shaft by the bearing, and the planetary gear shaft is fixed on the planet carrier On the top, the planet carrier (5) is fixed on the end face of the inner end cover (4), which is characterized in that: (a) the built-in end cover (4) is used in the base (1) to separate the quasi-planetary drive from...

Embodiment 2

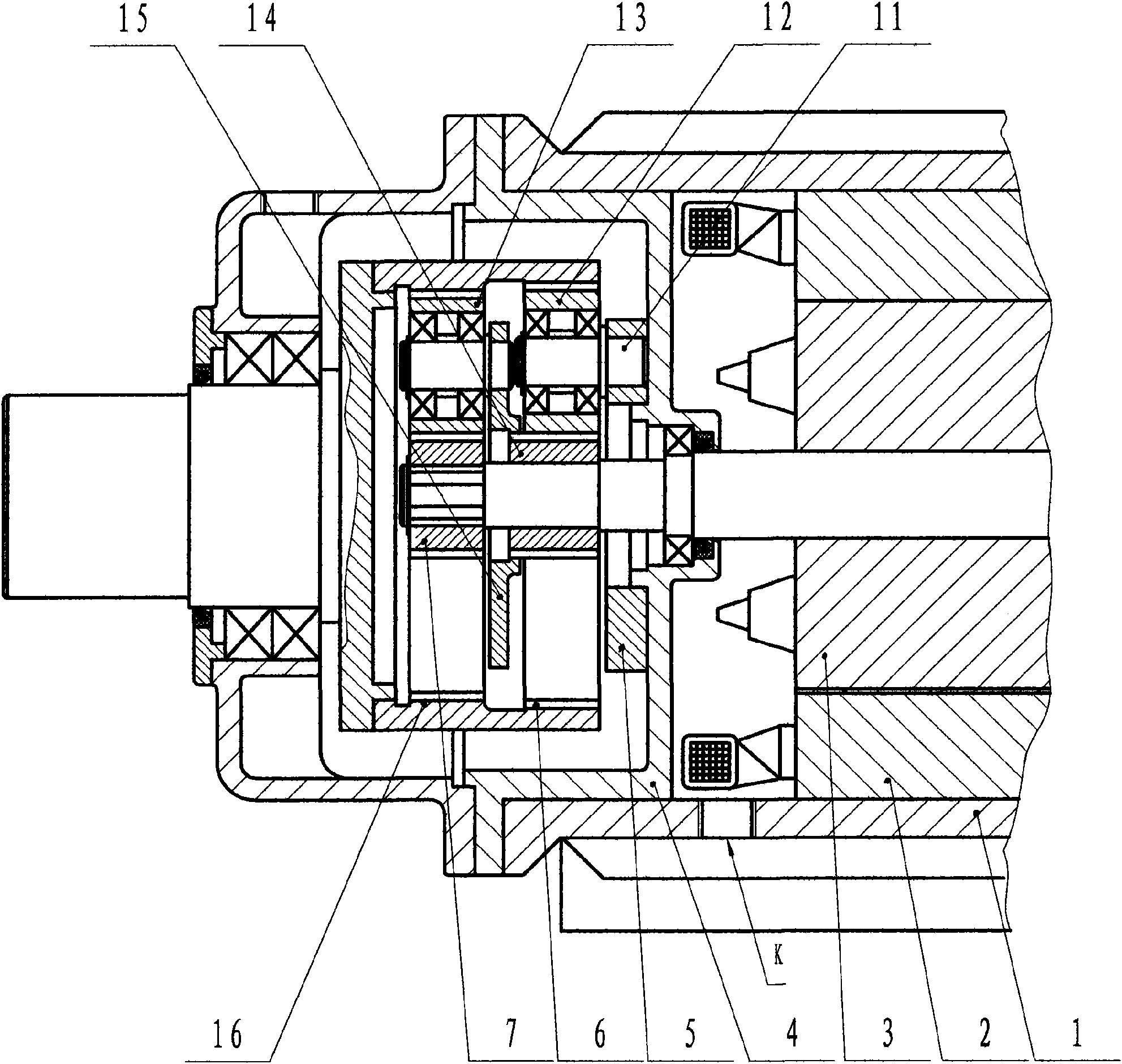

[0018] Such as figure 2 As shown, the epicyclic gear train is a closed differential gear train composed of quasi-planetary transmission and planetary differential, wherein: the planetary differential is composed of a sun gear (7) and a planetary gear (13) connected to the rotor shaft (3). , planetary carrier (15) and internal gear (16); Quasi-planetary transmission is made up of sun gear (14), planetary gear (12), planetary carrier (5) and internal gear (6), two internal gears (6), (16) is integrated and connected with the disc of the output shaft (10), the planetary carrier (15) is connected with the sun gear (14) of the quasi-planet by relying on the involute spline in the inner hole, and the sun gear (14) is vacantly sleeved on the rotor shaft Above, the planet carrier (5) is fixed on the end face of the embedded end cover (4), the planet wheel (12) is supported on the planet wheel shaft (11) by the bearing, and the planet wheel shaft is fixed on the planet carrier (5).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com