Complex oil displacing method suitable for large well spacing condition of offshore oil field

A composite flooding and offshore oil field technology, applied in wellbore/well components, earthwork drilling, fluid production, etc., can solve the problems of oil layer damage, high surfactant requirements, and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Due to the special situation of oil production in offshore oilfields, it is difficult to intensify the well pattern. From the actual situation, large well spacing is often used for construction and production. Now, combined with the large well spacing conditions of the "reverse nine-point well pattern" commonly used in the Bohai oil area, the oil displacement is specifically explained. The technical scheme of the method (if the well pattern adopts the five-point method, the streamline can be adjusted appropriately, and the same method can be used for processing).

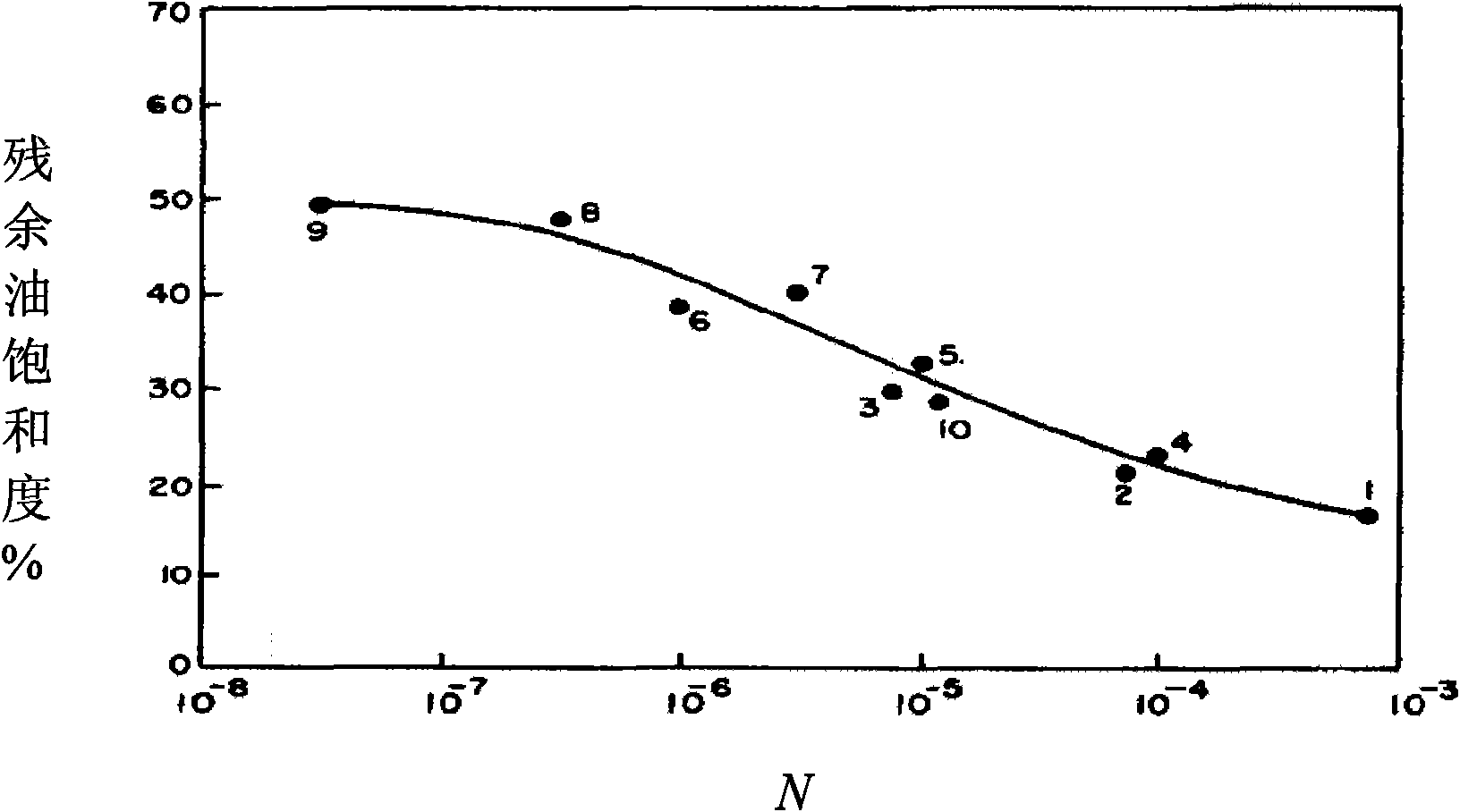

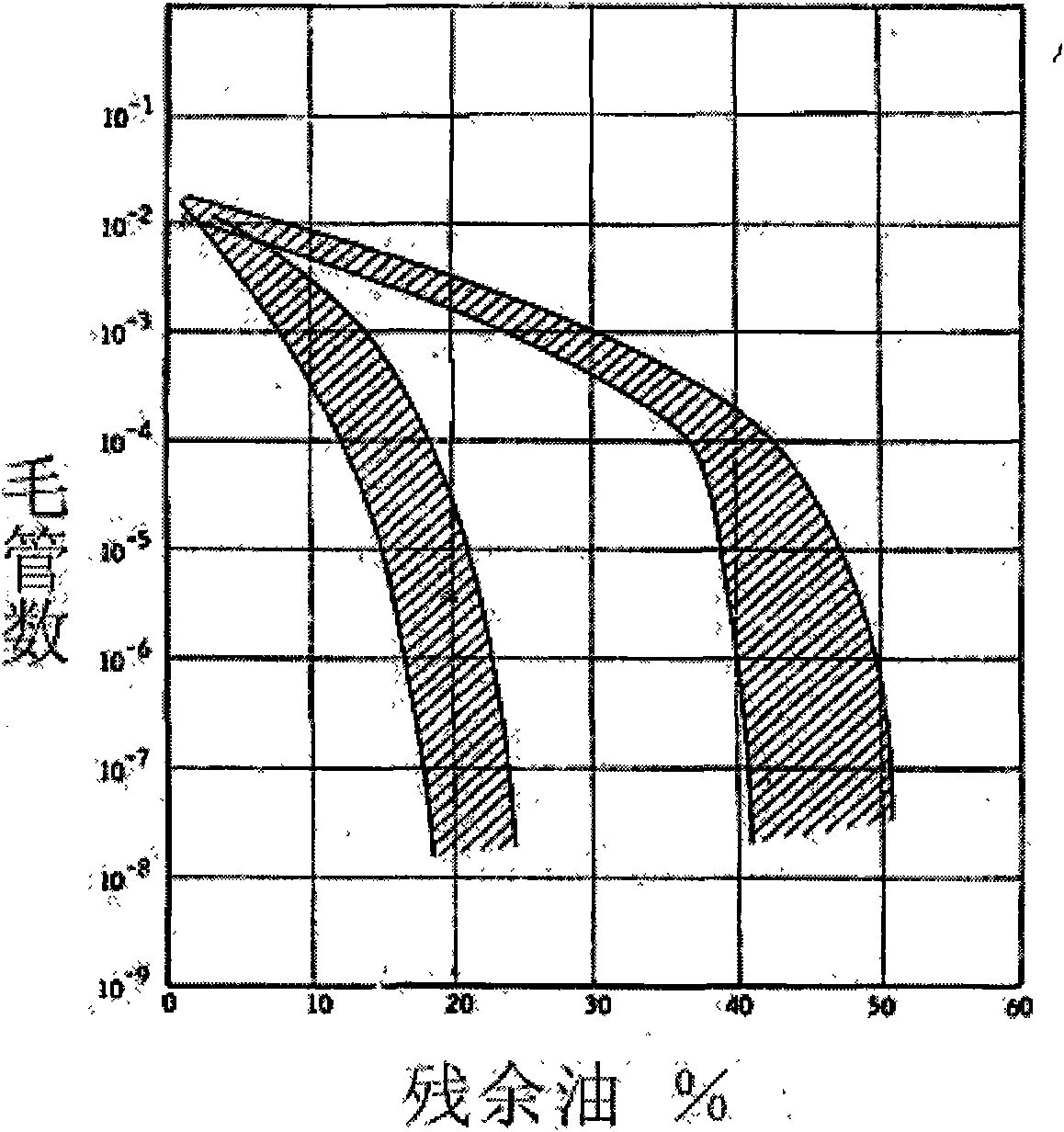

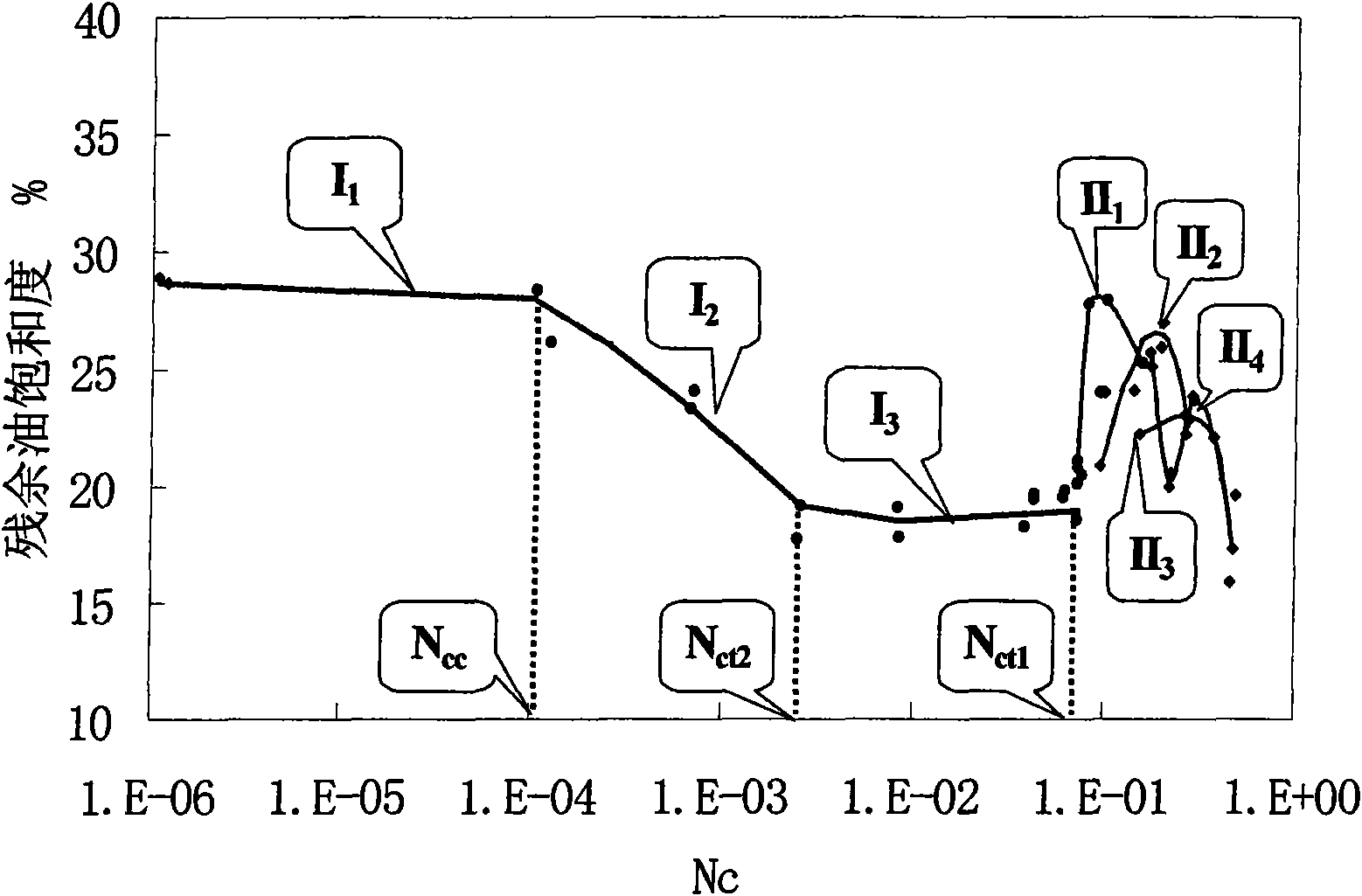

[0034] 1. Establishment of interfacial tension of oil displacement system and underground working viscosity

[0035] Numerical simulation research shows that the injection rate of well group in JZ9-3 oilfield is 0.072Vp / a per year. Assuming that the porosity of the oil layer is 0.26, it can be calculated that the average annual fluid injection per m oil layer of a single well is about 1.1981×10 4 m 3 , base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com