Turbulent baffle heat transfer enhancing device with jet impingement function

A technology of jet impact and enhanced heat transfer, which is applied in the direction of blade support components, engine components, machines/engines, etc., can solve the problems of not being able to satisfy the closed circulation of cooling medium, narrow area space, complex structure, etc., and achieve closed Circulation requirements, uniform temperature distribution, good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

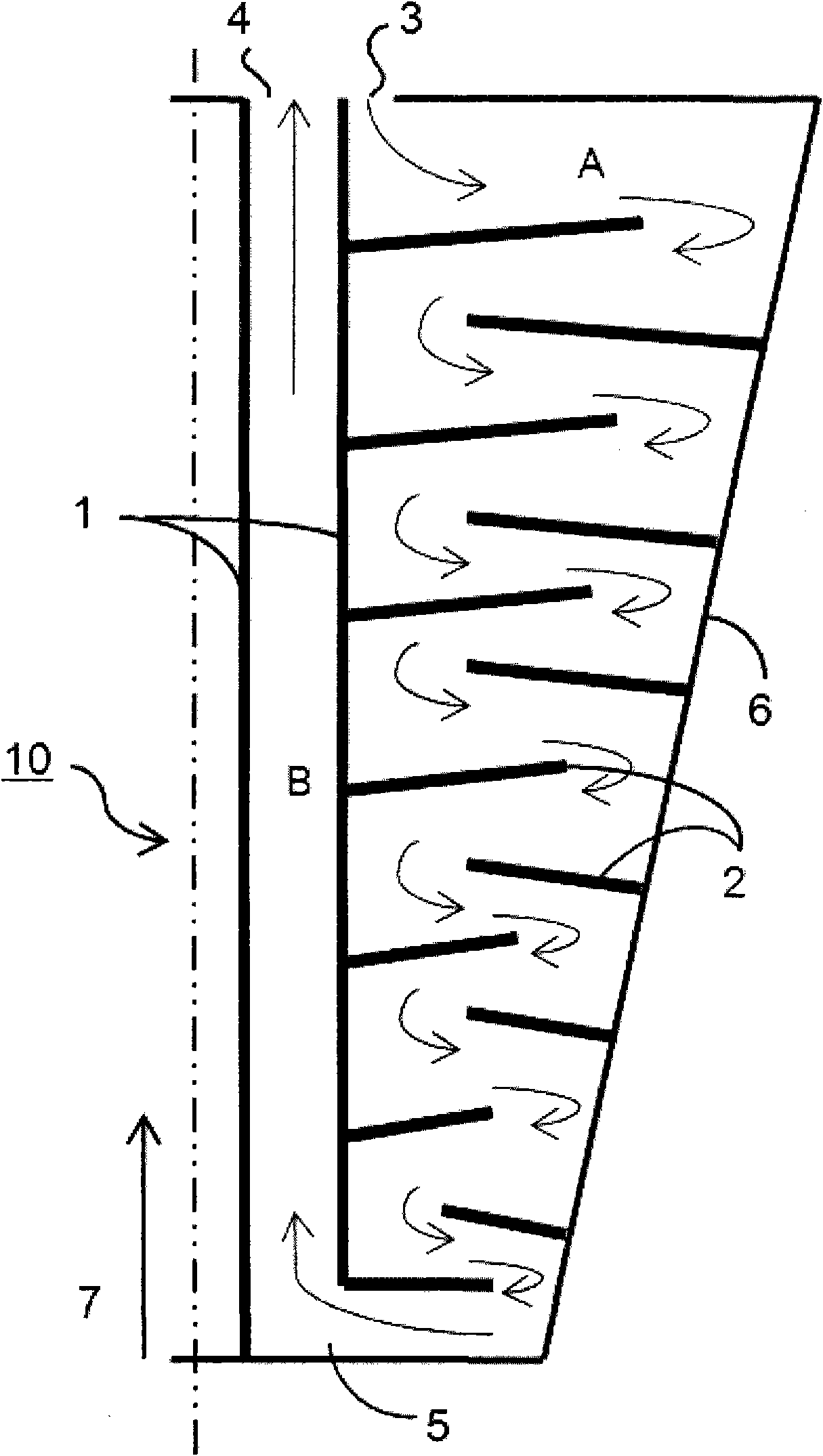

[0010] like figure 1 As shown, it is a schematic diagram of the cooling structure of the turbulent baffle with jet impact effect and the flow path of the cooling medium applied to the trailing edge of the turbine blade according to the present invention. In the internal cavity of the turbine blade trailing edge part 10, along the span direction, the partition plate 1 is divided into two parts, one part is channel A, and the other part is channel B, the width of channel A is greater than the width of channel B, two channels A, B is provided with openings at the upper ends of the blades, separated by partitions 1, one is the inlet 3 of passage A, and the other is the outlet 4 of passage B, and passages A and B communicate at the tail end 5 of the blades. A plurality of baffles 2 are arranged in the inner cavity of the passage A in a direction perpendicular to the spanning direction, and the plurality of baffles 2 are arranged parallel to each other alternately to form a serpenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com