Rotary piston engine

A technology of rotating pistons and engines, which is applied in the direction of internal combustion piston engines, combustion engines, machines/engines, etc., and can solve problems such as complex structures, reciprocating inertial forces and moments of inertia that cannot be completely balanced, and unfavorable fuel combustion and diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

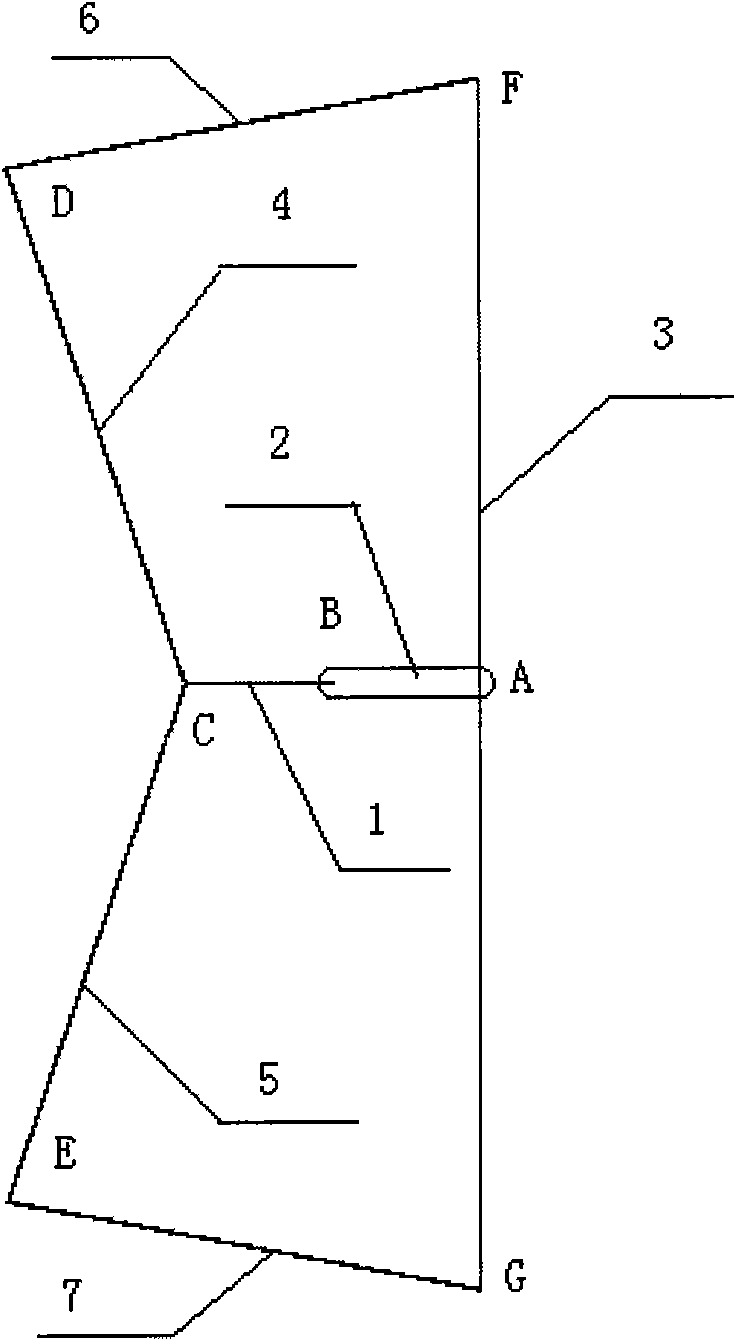

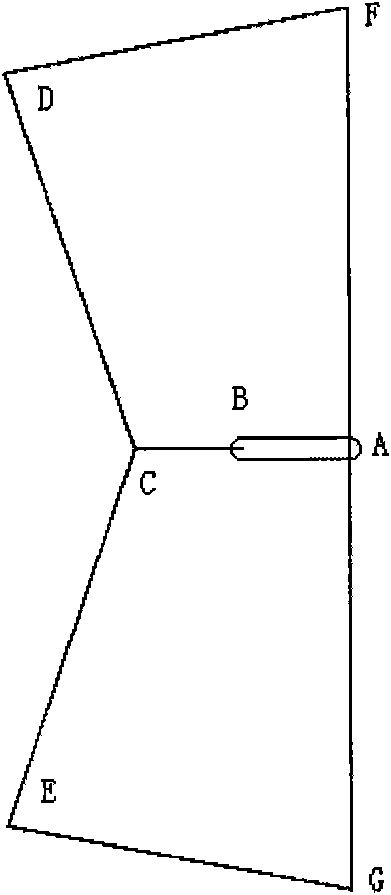

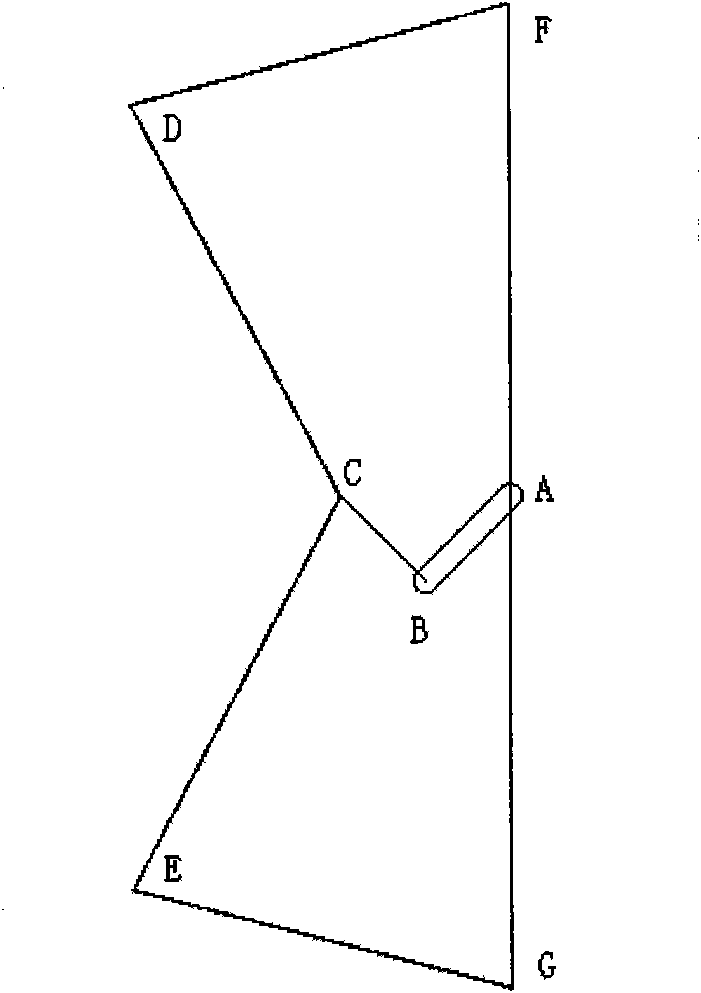

[0031]As shown in Figure 1, draw a simplified structural diagram of the engine. If the output shaft 1 rotates around point C relative to the fixed cylinder, the internal eccentric shaft 2 rotates around point B relative to the output shaft 1, and the rotor 3 rotates around point A. Since the rotational speed ratio of the inner eccentric shaft 2 is 1:-2:1, and the eccentricity of the output shaft, namely the BC length, is equal to the eccentricity of the inner eccentric shaft, namely the AB length, then point A will always move back and forth on a horizontal line segment, The length from the two ends of the line segment to point C is AB+BC. Since the rotating speed of the rotor relative to the fixed cylinder is zero, the two ends F and G on the rotor move similarly to point C, and they all move back and forth on a line segment. The length of the connecting rod 6 is DF, the length of the connecting rod 7 is EG, the length of the push rod 4 is DC, and the length of the push rod 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com