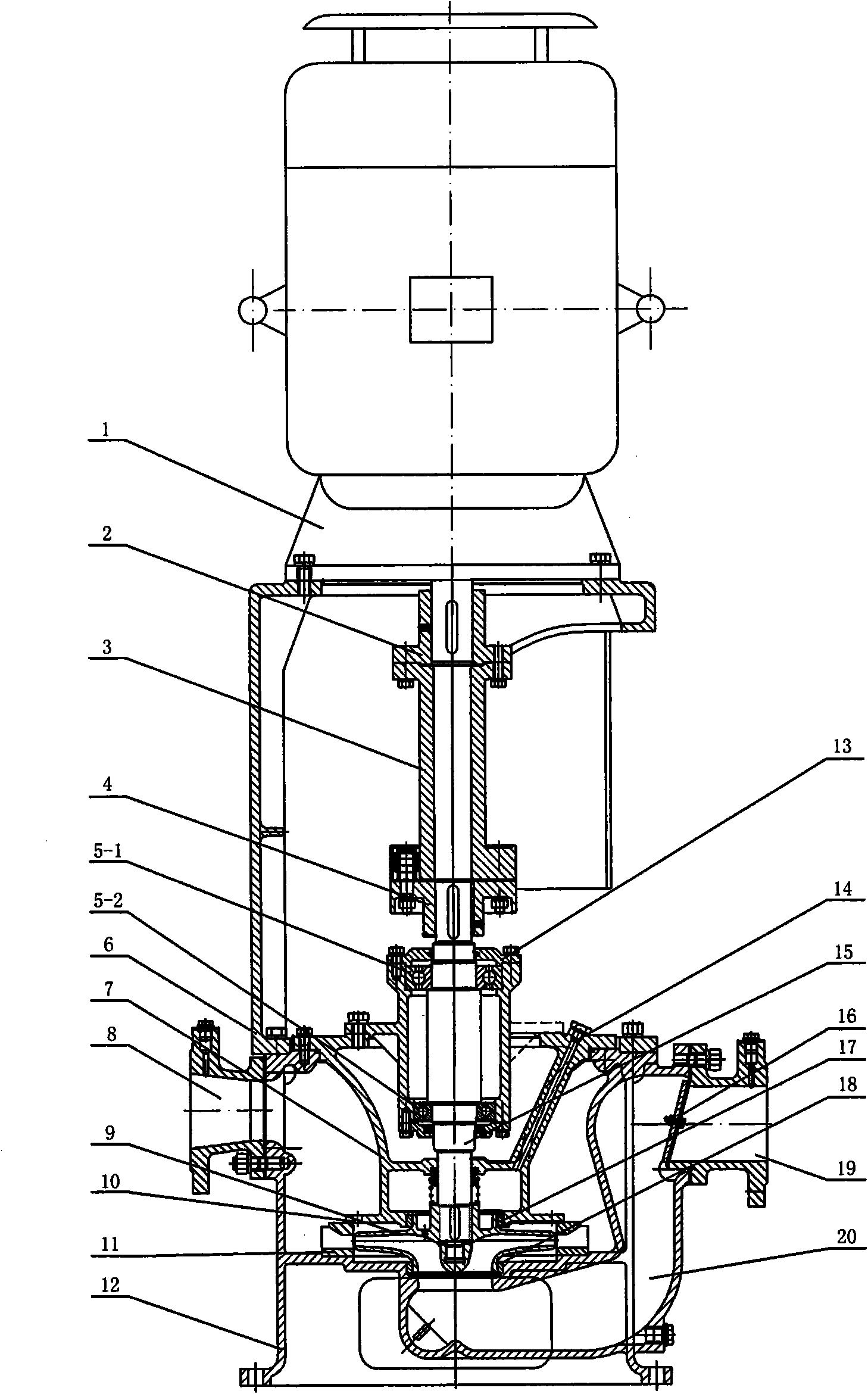

Middle-connecting type vertical self-priming centrifugal pump

A centrifugal pump, Zhonglian technology, applied in the field of Zhonglian vertical self-priming centrifugal pump, can solve the problems of poor self-priming effect, large volume, affecting the working performance of the pump, etc., and achieve the effect of preventing backflow and ensuring working performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention comprises a pump body with a pump chamber and an impeller 9 driven by a motor 1 through a pump shaft 14 in the pump body 12. A suction pipe 18 and a discharge pipe 8 communicating with the pump body 12 are provided in the pump body 12. The pump body 12 is provided with a guide vane 11 corresponding to the impeller 9, and a water inlet glue valve 16 is provided at the suction pipe 19. There is a radial gap of 2-3mm between the guide vane 11 and the impeller 9, the inner wall of the guide vane 11 is formed with a flow channel facing the outer peripheral side of the impeller 9, the upper part of the guide vane 11 is provided with a return hole 10, the entrance of the impeller 9 and Sealing rings 17 and 18 are arranged between the pump body 12, and the sealing gap is between 0.3-0.5mm, and the motor 1 is arranged on the motor frame 6.

[0011] The pump shaft 14 of the present invention is connected through the pump coupling 4, the intermediate coupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com