Optical glass optical homogeneity test device and test method

A technology of optical uniformity and testing device, applied in the direction of testing optical performance, etc., can solve the problems of high cost, expensive interferometer, low accuracy of interferometer, etc., and achieve the effects of low cost, convenient testing method and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

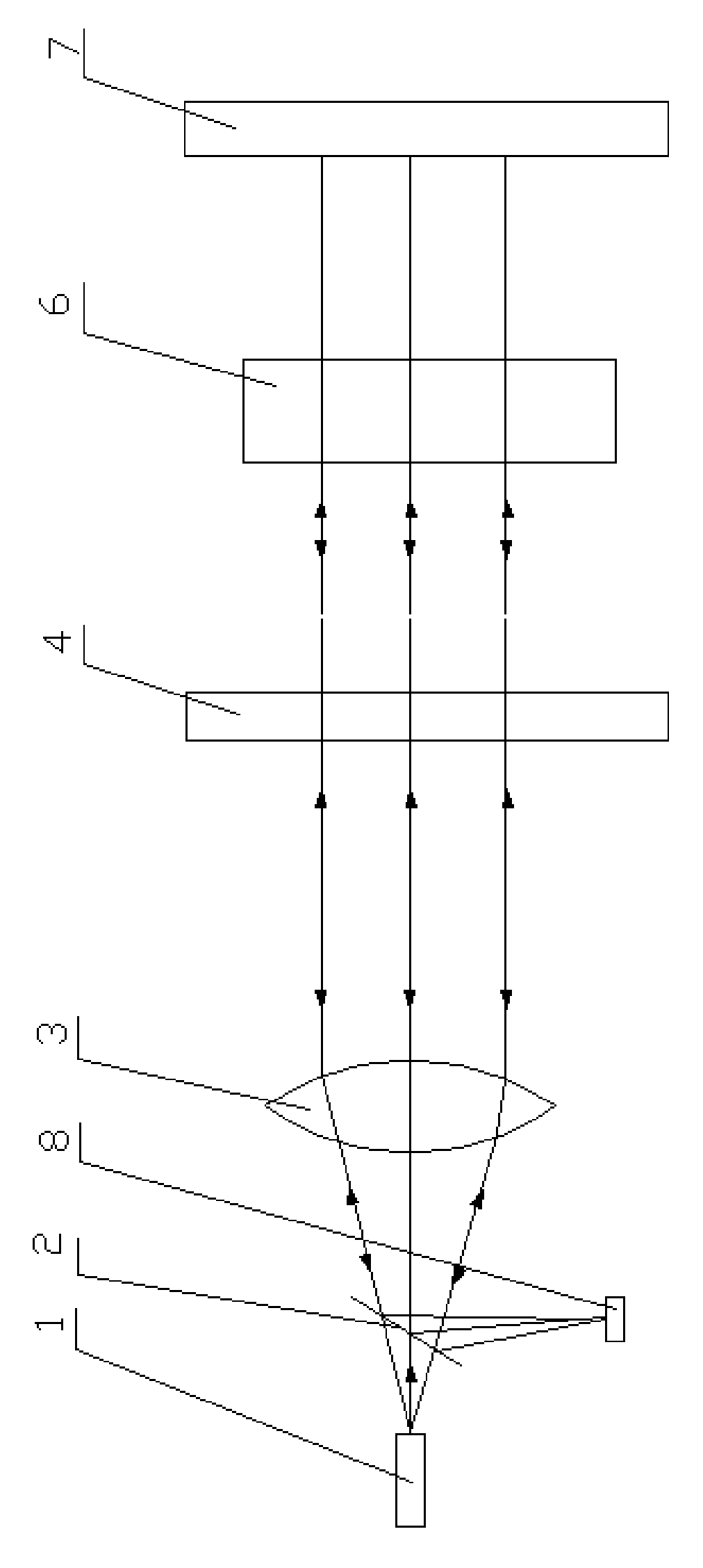

Image

Examples

Embodiment Construction

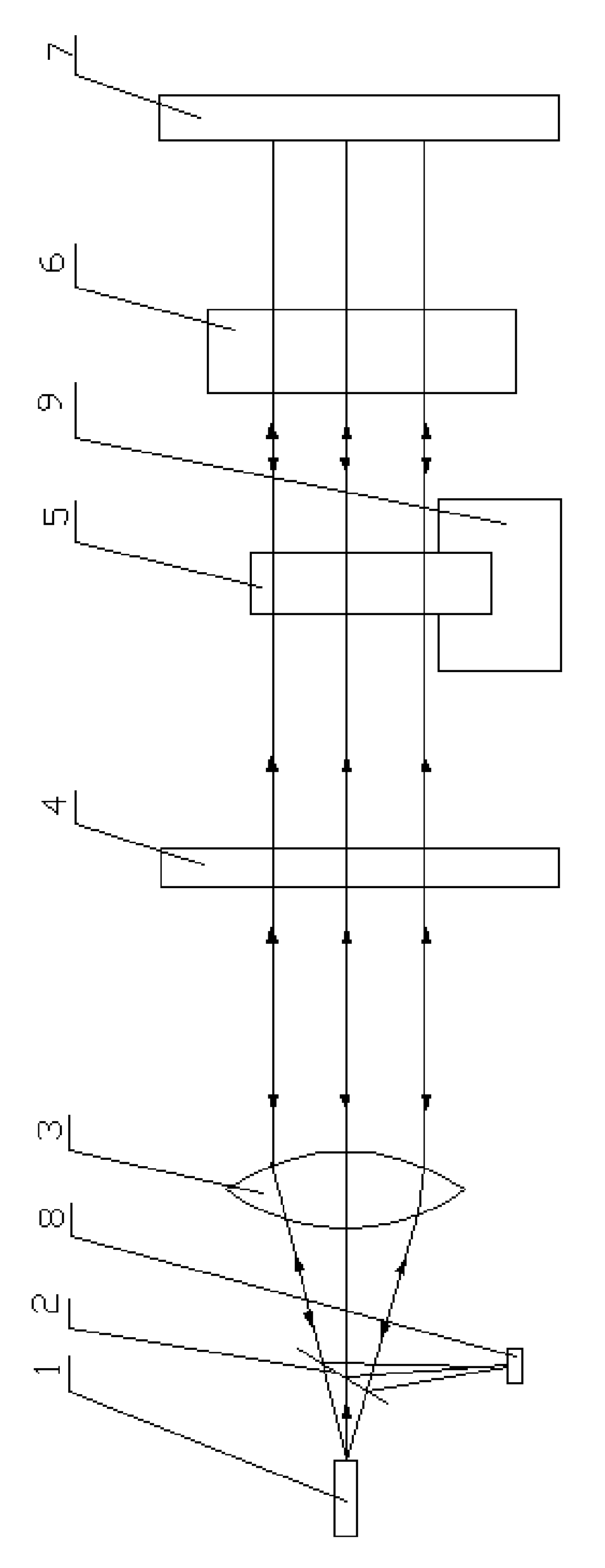

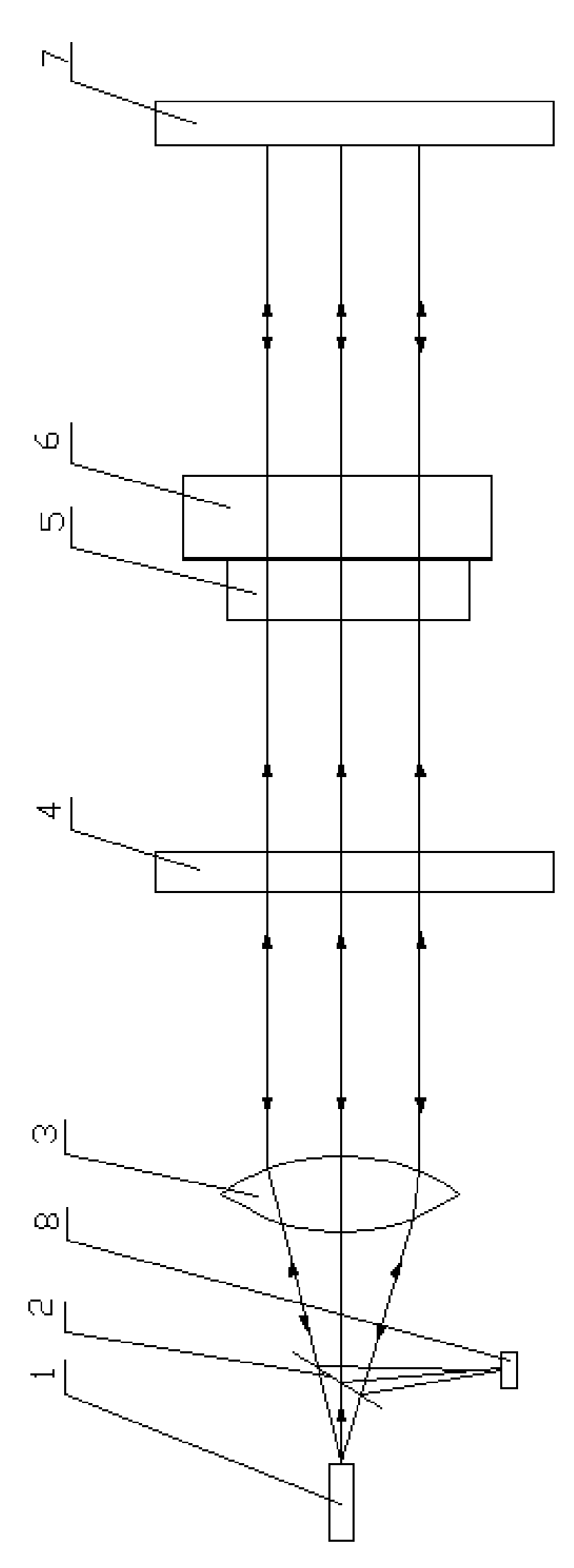

[0019] Such as figure 2 As shown, the device of the present invention is to increase and place a direction discrimination standard sample 5 between the lens 4 and the reflector 7 on the existing Fizeau interferometer, and one side of the direction discrimination standard sample 5 is made into a standard plane, and the other side Make a surface with a POWER value, and the PV values in each direction are equal, along the direction of the light path, the surface with the POWER value of the direction discrimination standard sample 5 is in front, and the standard plane is behind, so that when the plane light wave passes through the direction discrimination standard sample 5 , will form an almost standard spherical wave.

[0020] The direction judging standard sample 5 can be used to judge the direction of light wave distortion in the optical uniformity test. The direction discrimination standard sample 5 is made of quartz glass, because the stability of quartz glass is better a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com