Method for measuring first pass retention of wet end rapidly

A measurement method and retention rate technology, which can be used in measuring devices, analysis of suspensions and porous materials, particle suspension analysis, etc., can solve problems such as inconvenience, large human error, and cumbersome operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

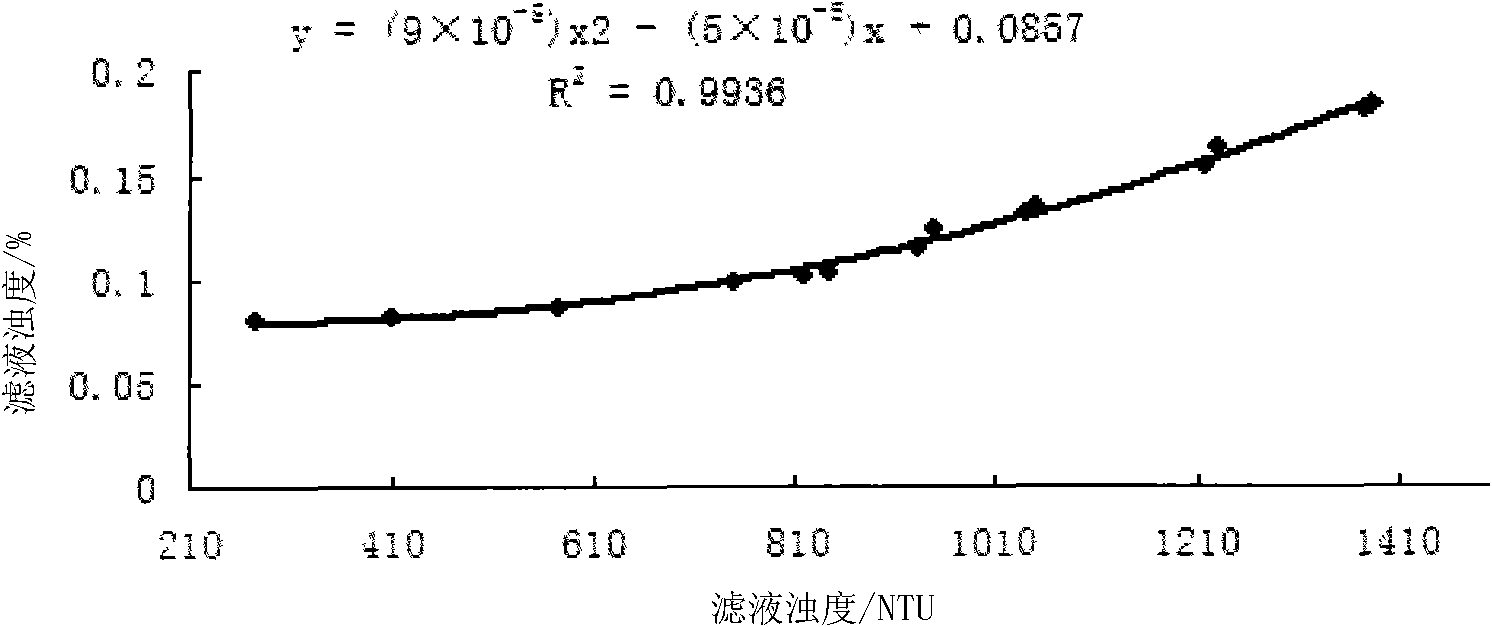

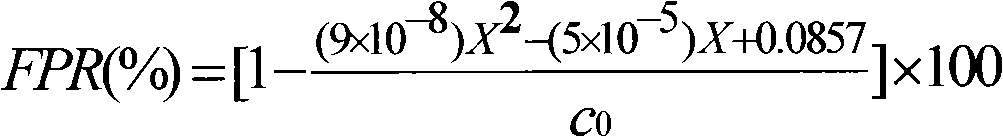

[0039] Embodiment: the method for rapid determination of primary retention rate of wet end of papermaking

[0040] 1. Experimental raw materials and main experimental instruments

[0041] 1.1 Experimental raw materials and auxiliary materials

[0042] Commodity bleached KP reed pulp board,

[0043] Filler Precipitated calcium carbonate (PCC), particle size less than 2μm content>98%,

[0044] Cationic polyacrylamide (prepared to a concentration of 0.01%), percol182,

[0045] 1.2 Experimental Instruments

[0046] Trough beater ZQS2, Northwest Institute of Light Industry Machinery Factory; DDJ dynamic water filter electro-craft, motomatic; Turbidimeter 2100P, American HACH Company; circulating water multi-purpose vacuum pump SHB-III, Zhengzhou Great Wall Technology Industry and Trade Co., Ltd. Company; GBJ-A fiber standard dissociator, Changchun Small Test Machine Factory.

[0047] 1.3 Research steps and methods

[0048] 1.3.1 Preparation of paper stock concentration

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com