Method for nondestructive examination of oxide thickness distribution in stainless steel tubes

A stainless steel tube, non-destructive testing technology, applied in the direction of electric/magnetic thickness measurement, electromagnetic measurement device, material magnetic variable, etc., can solve the problems of incompatibility, inability to effectively detect the boundary condition of oxide scale, boundary insensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

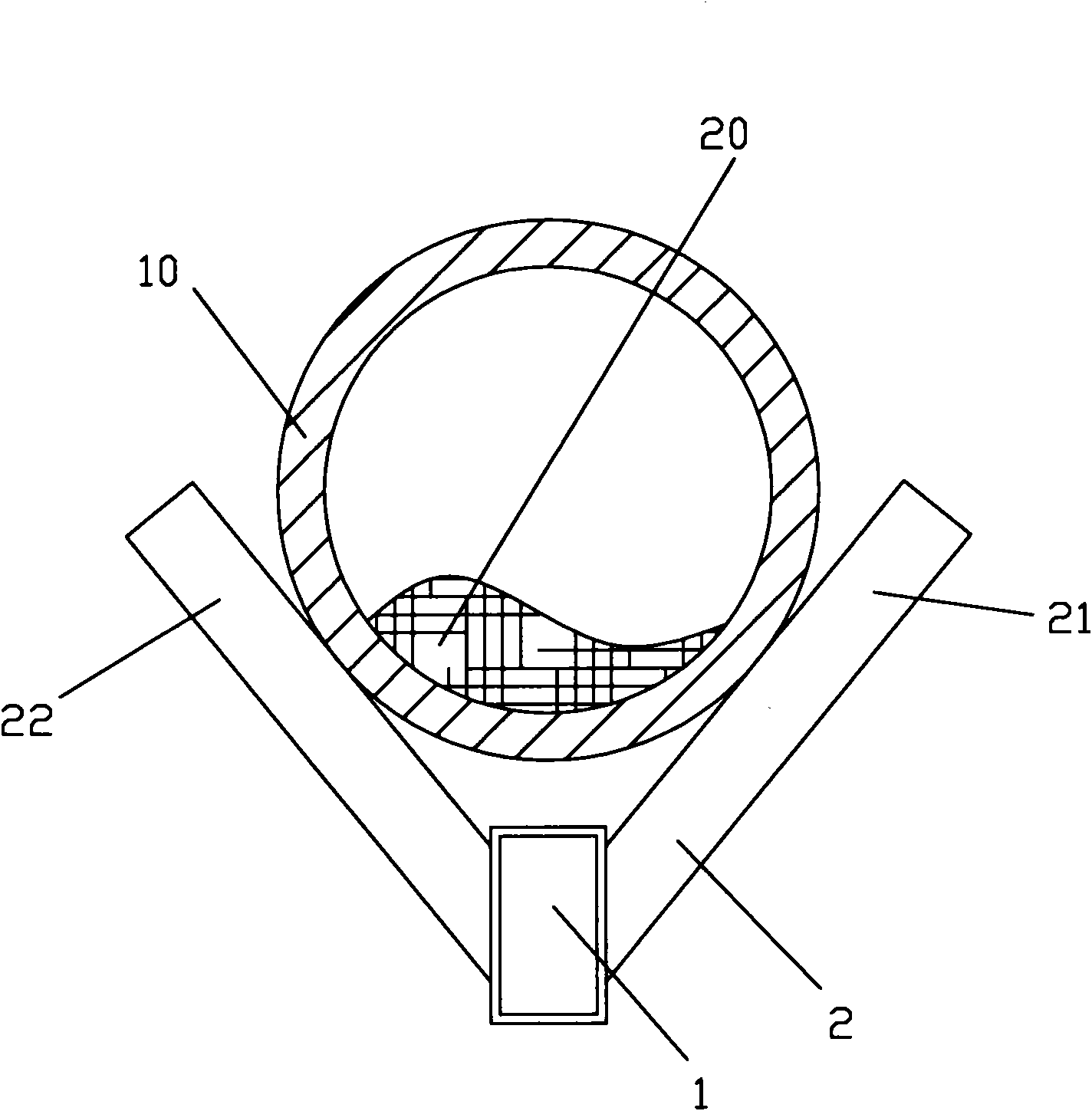

[0030] Embodiment one, see figure 1 As shown, a method for non-destructive testing of oxide scale thickness distribution in stainless steel pipes of the present invention comprises the following steps:

[0031]a. The eddy current sensor 1 is attached to a position on the outer wall of the elbow section (i.e. the U-shaped pipe section) of the stainless steel pipe 10; the eddy current sensor 1 is mounted on an adaptive probe bracket 2, and the adaptive probe bracket 2 includes The two arms are the first arm 21 and the second arm 22, the first arm 21 and the second arm 22 are pivotally connected and connected by a spring, so that the first arm 21 and the first arm 22 can be opened to each other to form any angle within 180 degrees , to adapt to different pipe diameters of stainless steel pipes; when the eddy current sensor 1 is installed on the self-adaptive probe bracket, it can be connected by thread, so that the eddy current sensor 1 can be adjusted up and down, so that the ed...

Embodiment 2

[0038] Embodiment 2, a method for non-destructive testing of oxide scale thickness distribution in stainless steel pipes according to the present invention, comprising the following steps:

[0039] A. Wrap the multi-channel eddy current sensors arranged in a linear array around the stainless steel pipe wall in a 360° manner around a circle of the wall of the elbow section of the stainless steel pipe (i.e. the U-shaped pipe section);

[0040] B. The eddy current sensors of each channel are respectively excited by the preset multi-frequency signal sent by the arbitrary waveform generator in the way of time-sharing excitation, and the multi-frequency excitation signal passes through the pipe wall of the stainless steel pipe to generate eddy current in the oxide skin;

[0041] C. The eddy current sensor corresponding to each channel picks up the eddy current induction signal of the oxide skin by the respective eddy current sensor, and the eddy current induction signal output by eac...

Embodiment 3

[0045] Embodiment 3, a method for non-destructive testing of oxide skin thickness distribution in stainless steel pipes according to the present invention, comprising:

[0046] Wrap the flexible multi-channel eddy current sensors arranged in an area array outside the wall of the bent pipe section (i.e. U-shaped pipe section) of the stainless steel pipe;

[0047] The eddy current sensors of each channel are respectively excited by the preset multi-frequency signal from the arbitrary waveform generator by the method of time-sharing excitation, and the multi-frequency excitation signal passes through the pipe wall of the stainless steel pipe to generate eddy current in the oxide skin;

[0048] The eddy current sensor corresponding to each channel picks up the eddy current sensor signal on the oxide scale, and the eddy current sensor signal output by each eddy current sensor is amplified, phase-sensitive detection, and frequency-mixed to process the interference signal and then sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com