Third-level cyclone separator with large handling capacity

A cyclone separator and processing capacity technology, which is applied to cyclone devices, devices whose axial directions of the cyclone can be reversed, etc., can solve the problems of equipment manufacturing and maintenance difficulty, inability to meet large processing capacity, and inability to achieve performance, etc. Achieve the effect of satisfying the three-rotation processing capacity, reasonable force and convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

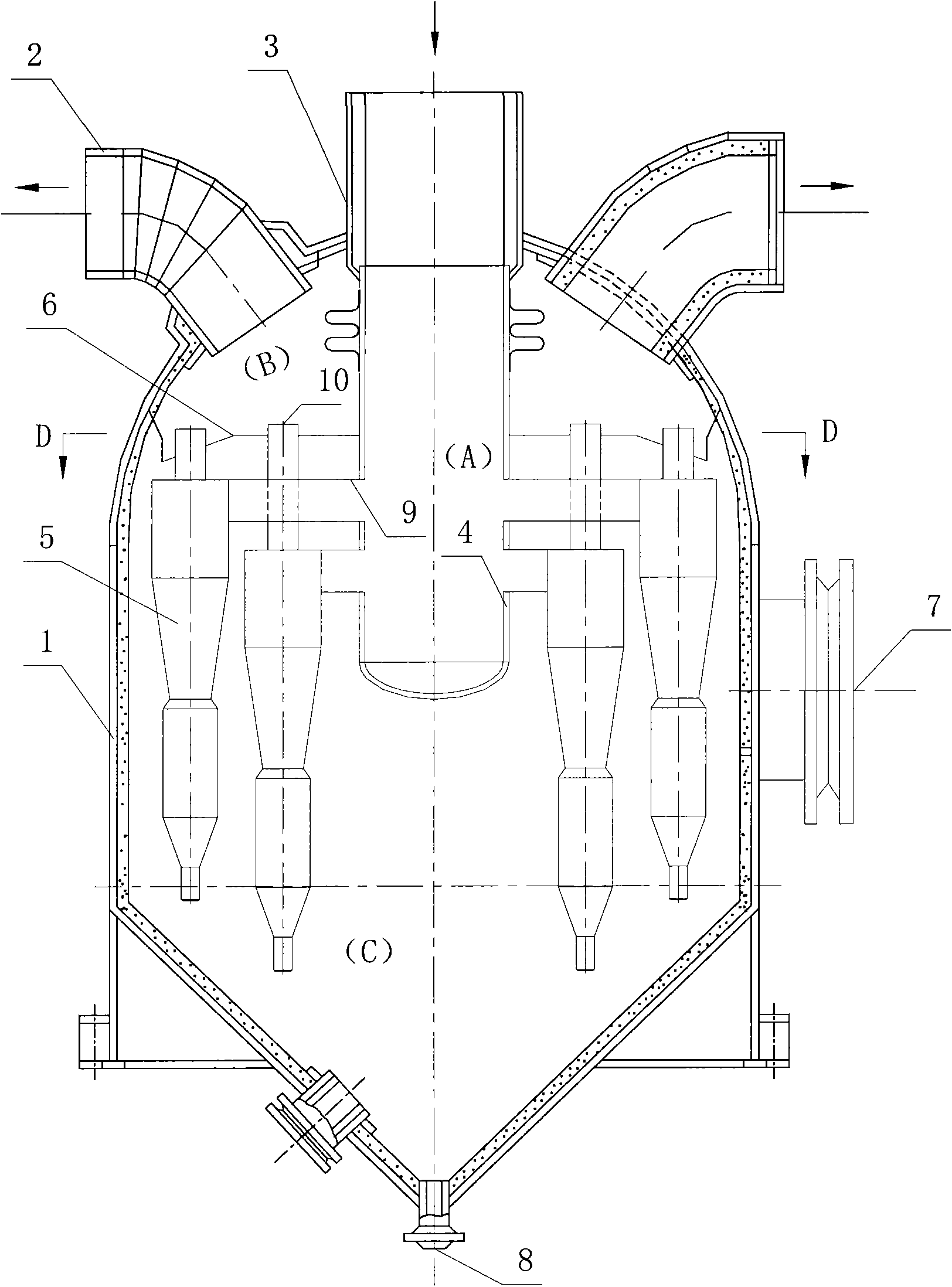

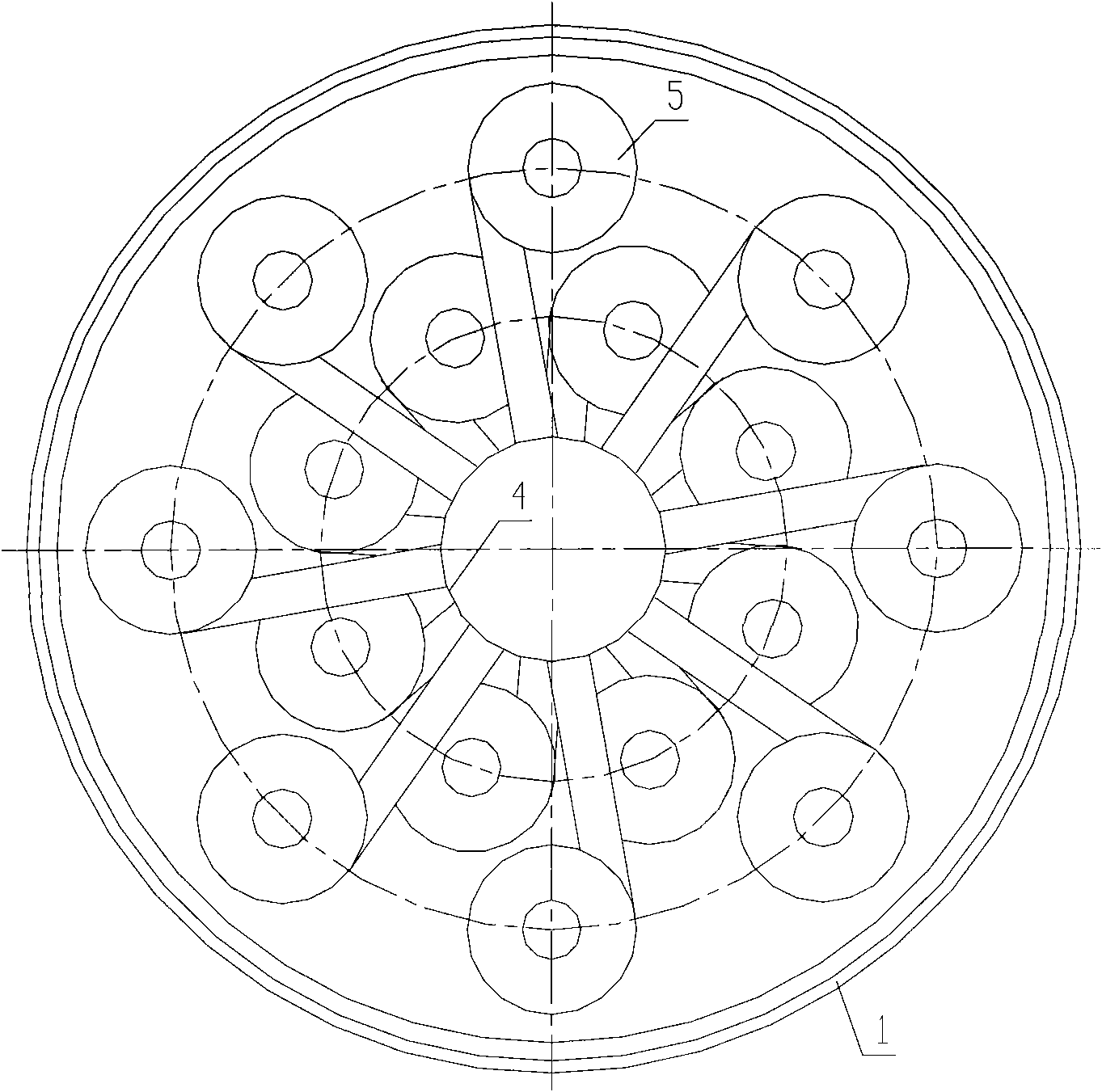

[0014] Such as figure 1 , figure 2 As shown, the large-capacity third-stage cyclone separator of the present invention includes a housing 1, a flue gas outlet 2, a flue gas inlet 3, a central pipe 4, a plurality of single cyclone separators 5, and a hanging plate 6. . The shell 1 is composed of a top head, a middle cylinder and a bottom cone. Wherein the flue gas outlet 2 and the flue gas inlet 3 are installed on the cover at the top of the housing 1 . A loading and unloading hole 7 is opened on the middle cylinder of the housing 1 to facilitate maintenance and replacement of internal components. The top in the housing 1 is horizontally arranged with a hanging plate 6, and the hanging plate 6 is composed of a central flat plate and a peripheral conical plate. A central tube 4 with a closed bottom is installed inwardly from the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com