Force synthesizing arm applied to redundant actuator system

An actuation system and redundancy technology, applied in the field of force synthesis arms, can solve the problems of redundant steering gear length, etc., and achieve the effects of improving structural reliability, convenient processing, and reducing regular maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings.

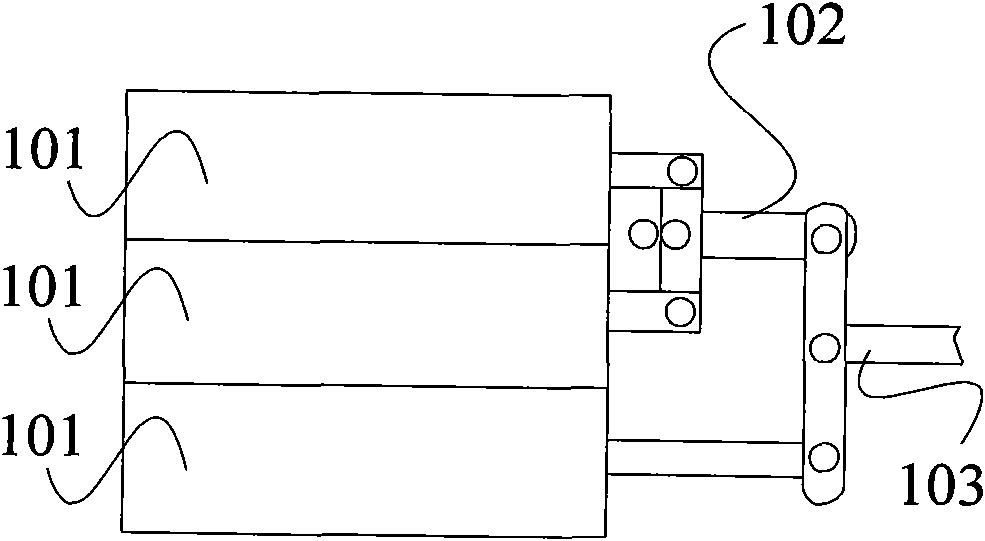

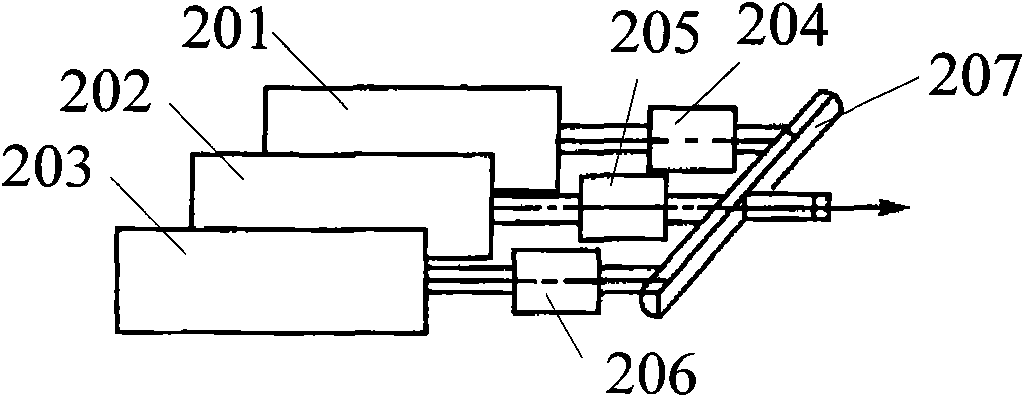

[0033] The present invention is a force synthesis arm applied to a redundant steering gear system, such as Figure 5 As shown, the redundant steering gear system includes steering gear A1, steering gear B2, steering surface 3, and force synthesis arm 4;

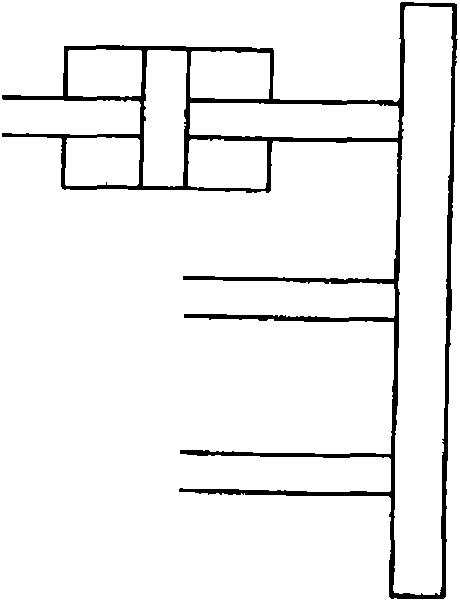

[0034] Such as Figure 6 As shown, the force synthesis arm 4 includes a slider 401 , a chute 402 , a passage A403 , a passage B404 , a synthesis rod 405 , and a main arm 406 .

[0035] There is a spherical hinge groove A407 at one end of the main arm 406 front of the force synthesis arm 4, and a chute 402 is opened at the other end, and a slide block 401 is embedded in the chute 402 of the force synthesis arm 4, so that the slide block 401 can be moved in the chute 402. Swipe in. There is a spherical hinge groove B408 on the slider 401; the length of the sliding groove 402 is determined according to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com