Direct-injection type ultraviolet vertical sterilizing device

A disinfection device, ultraviolet technology, applied in the direction of light water/sewage treatment, animal husbandry, fish farming, etc., can solve the problems of ineffective killing of harmful bacteria and viruses, high cost, low efficiency, etc., to reduce cost, Cost reduction and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

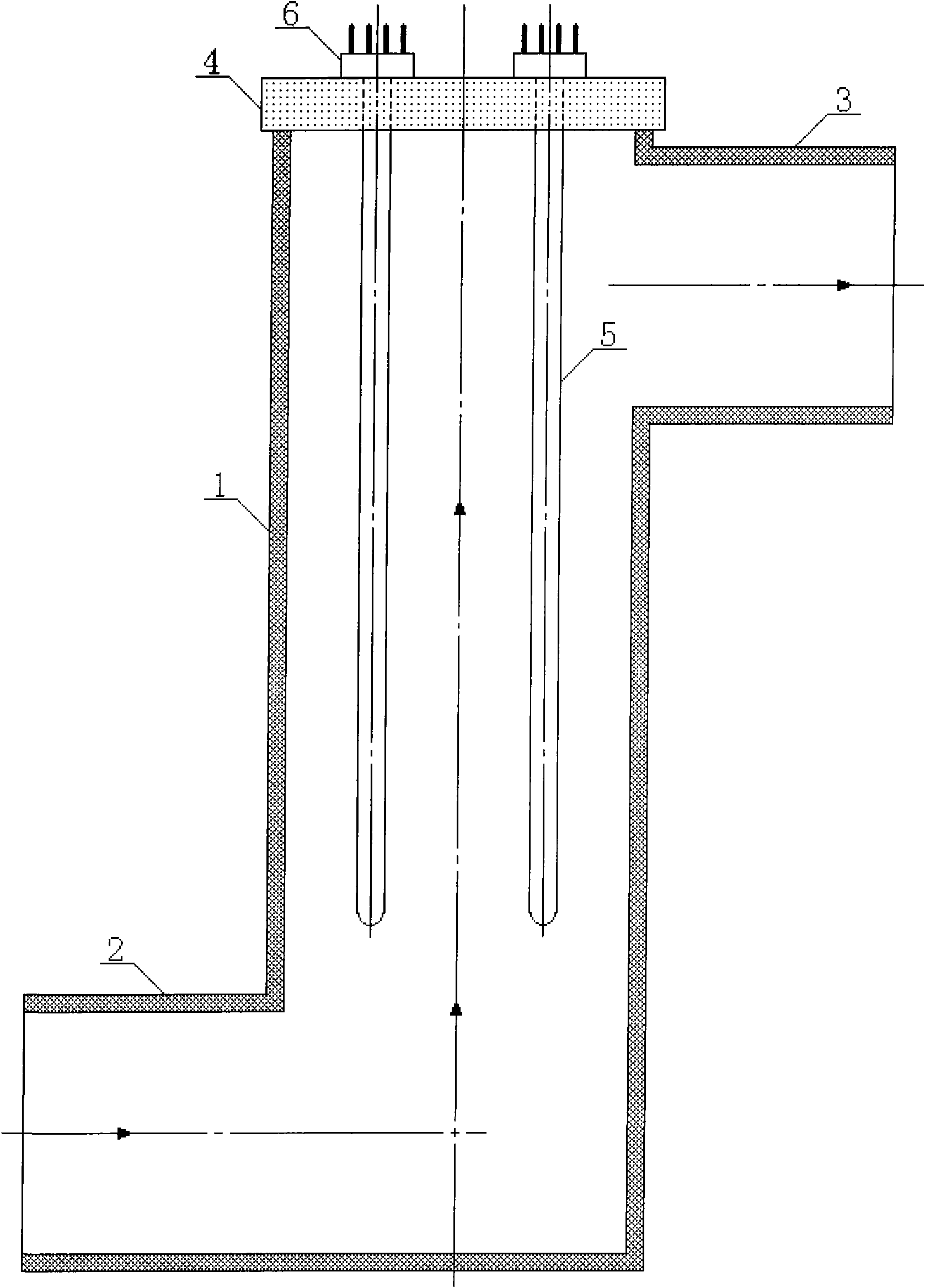

[0017] This example is an ultraviolet disinfection well of a circulating aquaculture system, which is located at the entrance of the degassing pool. The cross section of the disinfection well is 700mm×700mm square, and it is equipped with 5 twelve ultraviolet disinfection lamps. The total power of the ultraviolet sterilizing lamp tube is 1080w, and the circulating water flow rate is 400m per hour 3 , The sterilization rate reached 97%.

[0018] Such as figure 1 As shown, the main body 1 of the device has an inner cavity. The water inlet 2 is located at the bottom of the device, and the water outlet 3 is located at the top of the device. The ultraviolet sterilizing and disinfecting lamp tubes 5 are evenly distributed, arranged vertically, and penetrate deep into the inner cavity. The ultraviolet sterilizing and disinfecting lamp tube 5 is installed on the waterproof isolation plate 4 by plugging, and the lamp port 6 is located above the waterproof isolation plate 4 .

[001...

Embodiment 2

[0021] This example is the ultraviolet sterilizing tank of the circulating aquaculture system, located at the outlet of the degassing tank, the cross section of the sterilizing tank is a rectangle of 6000mm * 600mm, equipped with 5 twenty-one ultraviolet sterilizing lamp tubes, and other structures are the same as in embodiment one. The total power of the ultraviolet sterilization and disinfection lamp tube is 1890w, and the circulating water flow rate is 800m per hour 3 , The sterilization rate reached 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com