Method for preparing multifunctional leaf fertilizer by using shrimp waste

A waste, multi-functional technology, applied in the fields of animal carcass fertilizer, application, organic fertilizer, etc., can solve the problems of lack of safety, difficult to achieve clean production, low amino acid and chitosan content in liquid organic fertilizer, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

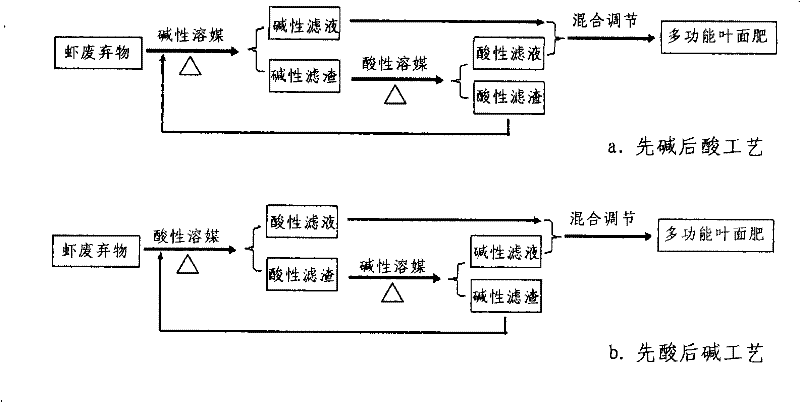

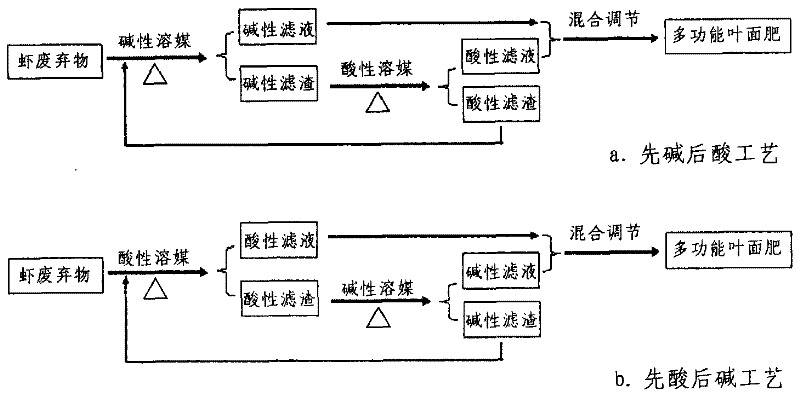

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing multifunctional foliage fertilizer by utilizing shrimp waste, comprising the steps in turn:

[0025] 1) get 10kg fresh shrimp processed shrimp waste, add 99% (wt %) potassium hydroxide and put it into a reaction tank at a temperature of 40° C. Vacuum degree of 0.020 ~ 0.098MPa under reduced pressure reflux hydrolysis, using interstitial air flow stirring or mechanical continuous stirring, after hydrolysis for 24 hours, filter under reduced pressure, collect alkaline filtrate and alkaline filter residue;

[0026] 2) In the collected alkaline filter residue, add 99% (wt%) phosphoric acid into the reaction tank according to the mass ratio of the alkaline filter residue to the acidic solvent as 1:3, and put it into the reaction tank at a temperature of 40°C and a vacuum of 0.020 to 0.098 Under reduced pressure and reflux under MPa for hydrolysis, use interstitial airflow stirring or mechanical continuous stirring, after 24 hours of hydrolysis, filter ...

Embodiment 2

[0030] A method for preparing multifunctional foliage fertilizer by utilizing shrimp waste, comprising the steps in turn:

[0031] 1) get 10kg fresh shrimp processed shrimp waste, add 99% (wt %) potassium hydroxide and put it into a reaction tank according to the mass ratio of shrimp waste and alkaline solvent as 1: 6, at a temperature of 40 ° C, Vacuum degree of 0.020 ~ 0.098MPa under reduced pressure reflux hydrolysis, using interstitial air flow stirring or mechanical continuous stirring, after hydrolysis for 24 hours, filter under reduced pressure, collect alkaline filtrate and alkaline filter residue;

[0032] 2) In the collected alkaline filter residue, add 99% (wt%) phosphoric acid into the reaction tank according to the mass ratio of the alkaline filter residue to the acidic solvent as 1:6, and put it into the reaction tank at a temperature of 40°C and a vacuum of 0.020 to 0.098 Under reduced pressure and reflux under MPa for hydrolysis, use interstitial airflow stirri...

Embodiment 3

[0036] A method for preparing multifunctional foliage fertilizer by utilizing shrimp waste, comprising the steps in turn:

[0037] 1) Get 10kg fresh shrimp processed shrimp waste, add 99% (wt %) potassium hydroxide and put it into a reaction tank at a temperature of 40° C. Vacuum degree of 0.020 ~ 0.098MPa under reduced pressure reflux hydrolysis, using interstitial air flow stirring or mechanical continuous stirring, after hydrolysis for 24 hours, filter under reduced pressure, collect alkaline filtrate and alkaline filter residue;

[0038] 2) In the collected basic filter residue, add 99% (wt%) phosphoric acid into the reaction tank according to the mass ratio of basic filter residue and acidic solvent as 1:12, and put it into a reaction tank at a temperature of 40°C and a vacuum of 0.020 to 0.098 Under reduced pressure and reflux under MPa for hydrolysis, use interstitial airflow stirring or mechanical continuous stirring, after 24 hours of hydrolysis, filter under reduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com