Ionic liquid recycling method

An ionic liquid and recycling method technology, applied in rayon recycling, textile and papermaking, sustainable manufacturing/processing, etc., can solve the problems of low purity of recycled liquid, difficult industrial production, high recycling cost, and shorten the heating time and stay The effect of short time and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

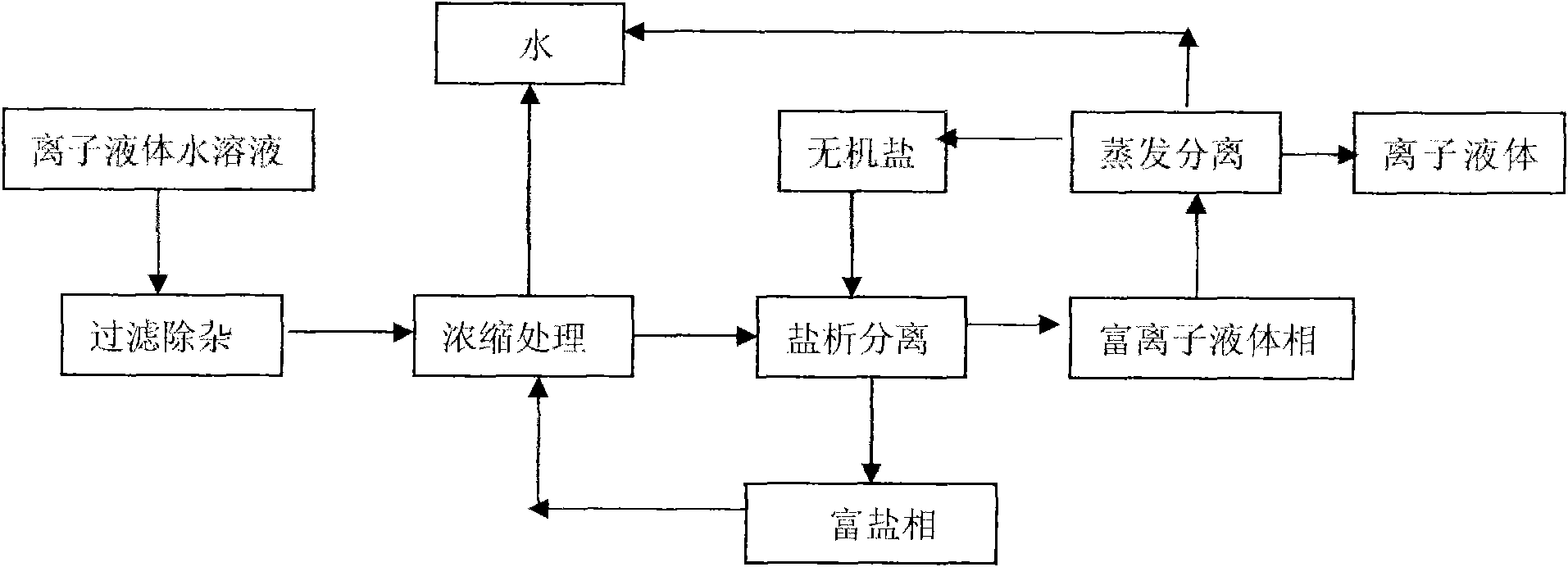

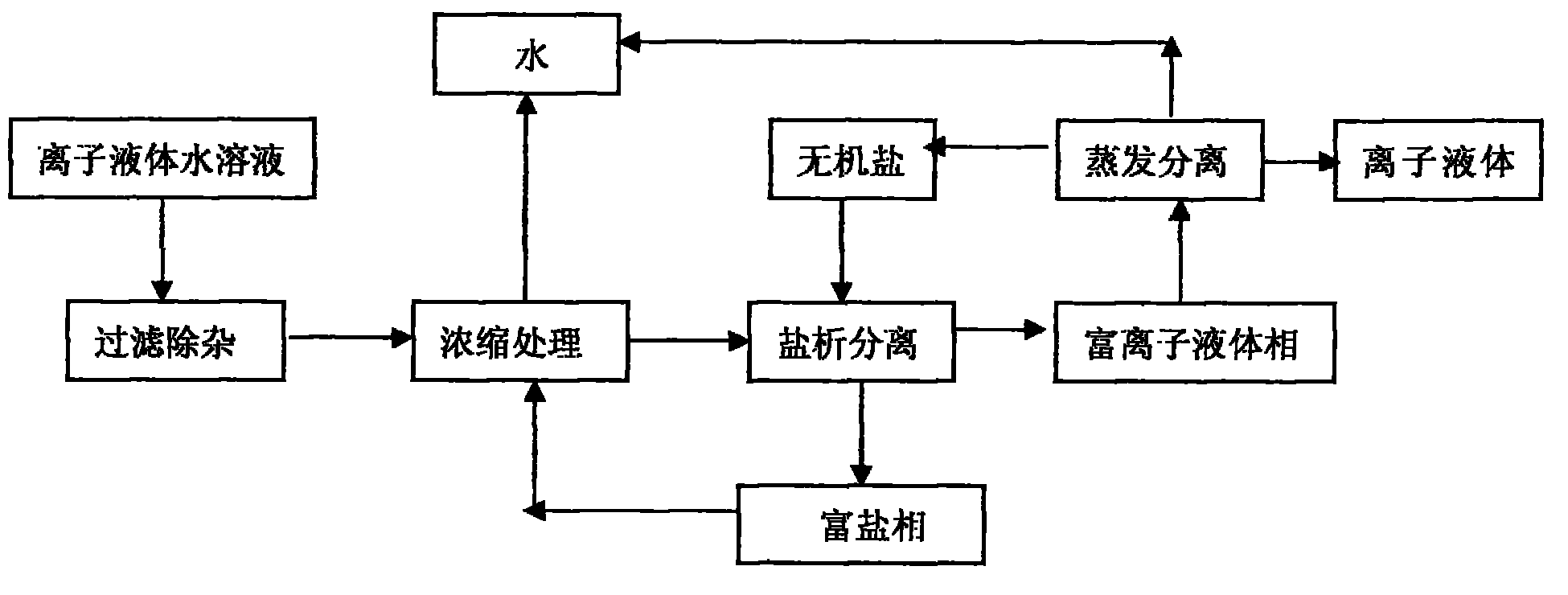

Method used

Image

Examples

Embodiment 1

[0028] Reclaim the mixed solution of spinning coagulation bath and refining washing liquid, the ionic liquid [BMIM]Cl concentration of the mixed solution is 5.2wt%, and the solution is passed through a PP filter element filter with a filter aperture of 5 microns to remove suspended impurities and particles and impurities such as sludge. The impurity-removed ionic liquid aqueous solution was concentrated with a reverse osmosis membrane at a pressure of 10.8Mpa and a temperature of 40°C to obtain a concentrated ionic liquid [BMIM]Cl with a concentration of 19.3%, and the concentrated water was reused in the production system. To the volume of 1m 3 Add concentrated liquid 0.62m to the salting-out separator 3 , and add 240Kg potassium phosphate (K 3 PO 4 ), stirred for 0.5 hour, left to stand for stratification and separation, obtained 108Kg of rich ionic liquid phase liquid, and the content of [BMIM]Cl in the rich ionic liquid phase was 82.6wt%, and the rich salt phase entered...

Embodiment 2

[0030] Reclaim the mixed solution of spinning coagulation bath and refining washing liquid, the ionic liquid [BMIM]Cl concentration of the mixed solution is 1.1wt%, and the solution is passed through a PP filter element filter with a filter aperture of 2 microns to remove suspended impurities and particles and impurities such as sludge. The impurity-removed ionic liquid aqueous solution was concentrated with a reverse osmosis membrane at a pressure of 6.7Mpa and a temperature of 35°C to obtain a 10.2% concentrated ionic liquid [BMIM]Cl, and the concentrated water was reused in the production system. To the volume of 1m 3 Add concentrated liquid 0.67m to the salting-out separator 3 , and add 280Kg potassium phosphate (K 3 PO 4 ), stirred for 0.5 hour, left to stand for stratification and separation, obtained 96Kg of rich ionic liquid phase liquid, and the content of [BMIM]Cl in the rich ionic liquid phase was 91.2wt%, and the rich salt phase entered the reverse osmosis syste...

Embodiment 3

[0032] Reclaim the mixed solution of spinning coagulation bath and refining washing liquid, the ionic liquid [BMIM]Cl concentration of the mixed solution is 3.6wt%, and the solution is passed through a PP filter element filter with a filter aperture of 10 microns to remove suspended impurities and particles and impurities such as sludge. The impurity-removed ionic liquid aqueous solution was concentrated with a reverse osmosis membrane at a pressure of 9.7Mpa and a temperature of 30°C to obtain a 15.4% concentrated ionic liquid [BMIM]Cl, and the concentrated water was reused in the production system. To the volume of 1m 3 Add concentrated liquid 0.58m to the salting-out separator 3 , and add 320Kg potassium phosphate (K 3 PO 4 ), stirred for 0.5 hour, left to stand for stratification and separation, obtained 89Kg of rich ionic liquid phase liquid, and the content of [BMIM]Cl in the rich ionic liquid phase was 82.8wt%, and the rich salt phase entered the reverse osmosis syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com