Thread clamping device of sock machine

A thread clamping and hosiery machine technology, which is applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of increasing labor intensity, reducing labor intensity, and high cost, so as to improve the quality of socks, reduce labor intensity, and reduce manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

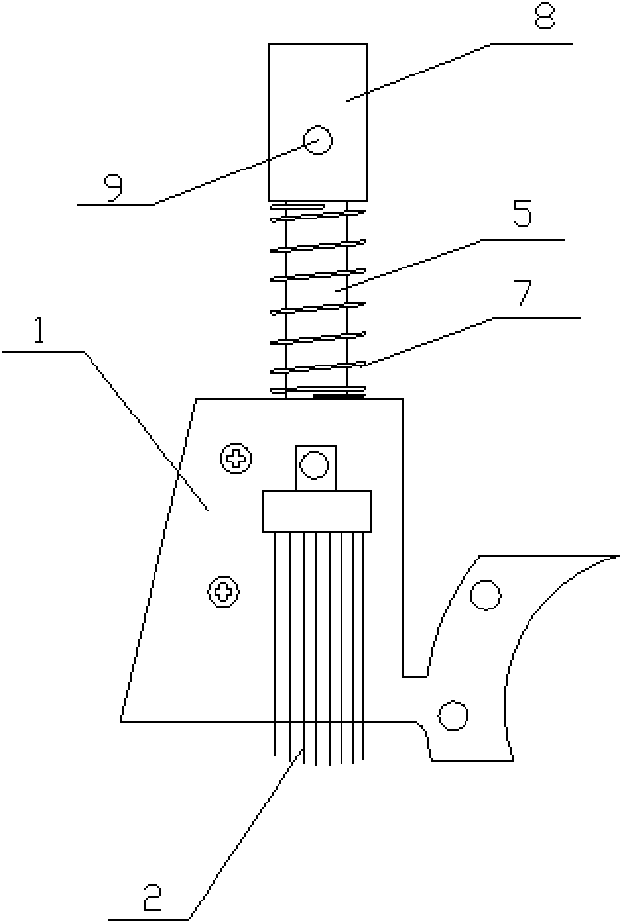

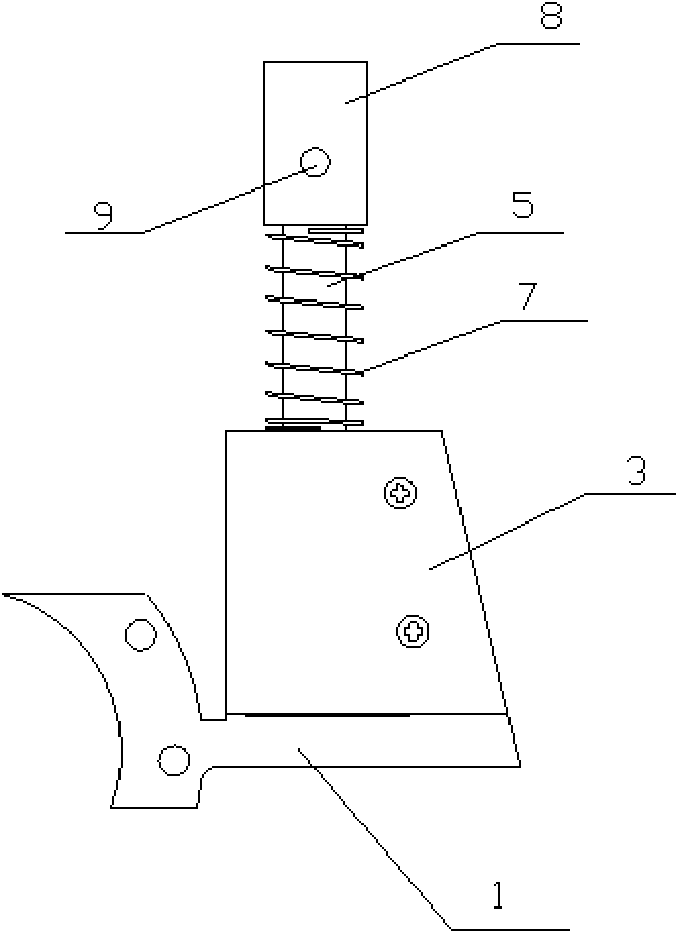

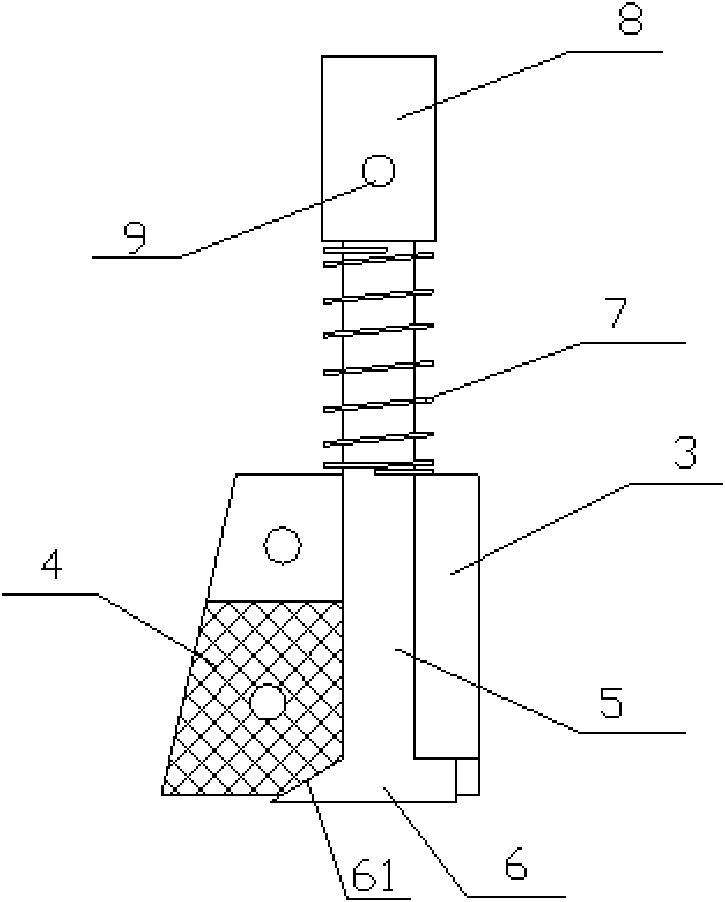

[0025] Embodiment 1: The hosiery machine clamping device of this embodiment, such as figure 1 , figure 2 , image 3 , Figure 6 As shown, it includes a brush holder 1 and a brush 2 installed on the brush holder 1. The back of the brush holder 1 is connected with a clamping cover 3 by bolts, and the clamping cover 3 and the brush holder 1 are surrounded by The cavity is installed with an elastic clamping piece 4 and a clamping rod 5 that can be raised or lowered. The bottom end of the clamping rod 5 has a clamping head 6. The clamping rod 5 and the clamping head 6 are integrally made. The top of the clamping rod 5 Stretch out the clamping cover plate 3 and the brush holder 1, the top of the clamping rod 5 is connected with the clamping rod fixing head 8, and the top of the clamping rod 5 extends into the clamping rod from the bottom of the clamping rod fixing head 8 to fix In the head 8, the two are connected together by bolts 9, and the spring 7 is set on the clamping rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com