Hydraulic auto-tensioner with double seal ring

A tensioner, hydraulic technology, applied in the direction of transmission, valve drive, engine components, etc., can solve the scratches and streaks in the plunger and housing plunger hole, automatic tensioner efficiency and performance characteristics , high cost of structural design and other issues, to achieve the effect of reducing the tendency of leakage, reducing the tendency of bonding, and improving the guiding characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

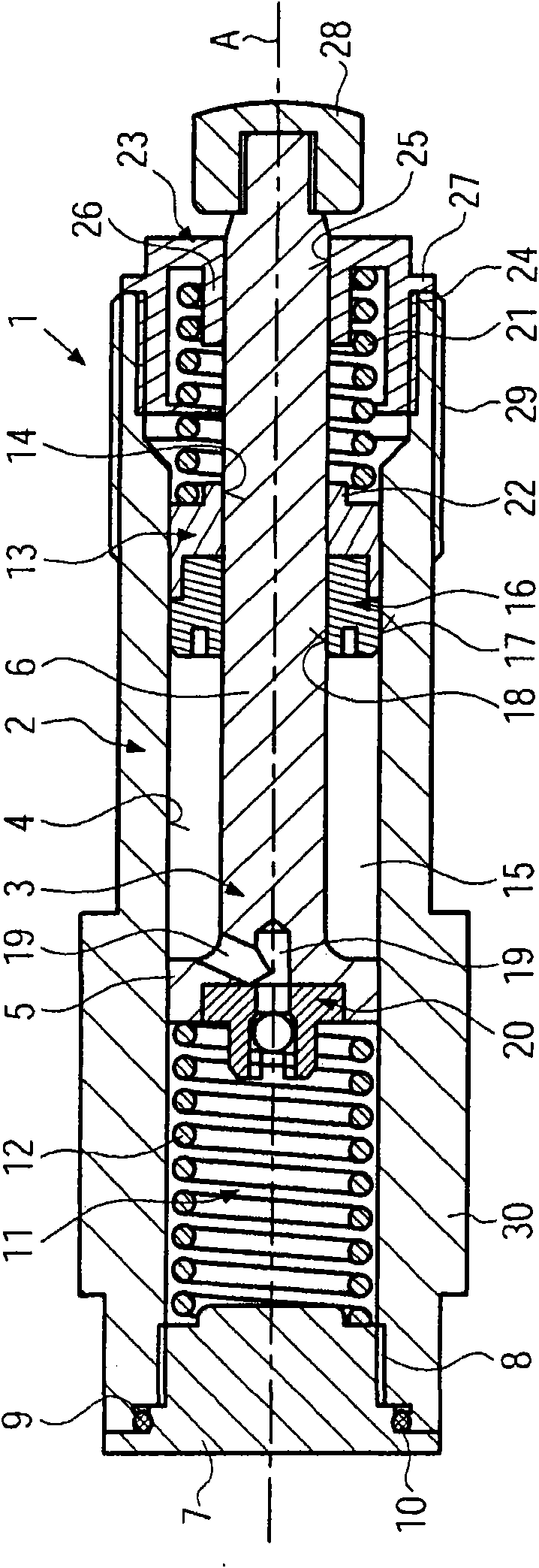

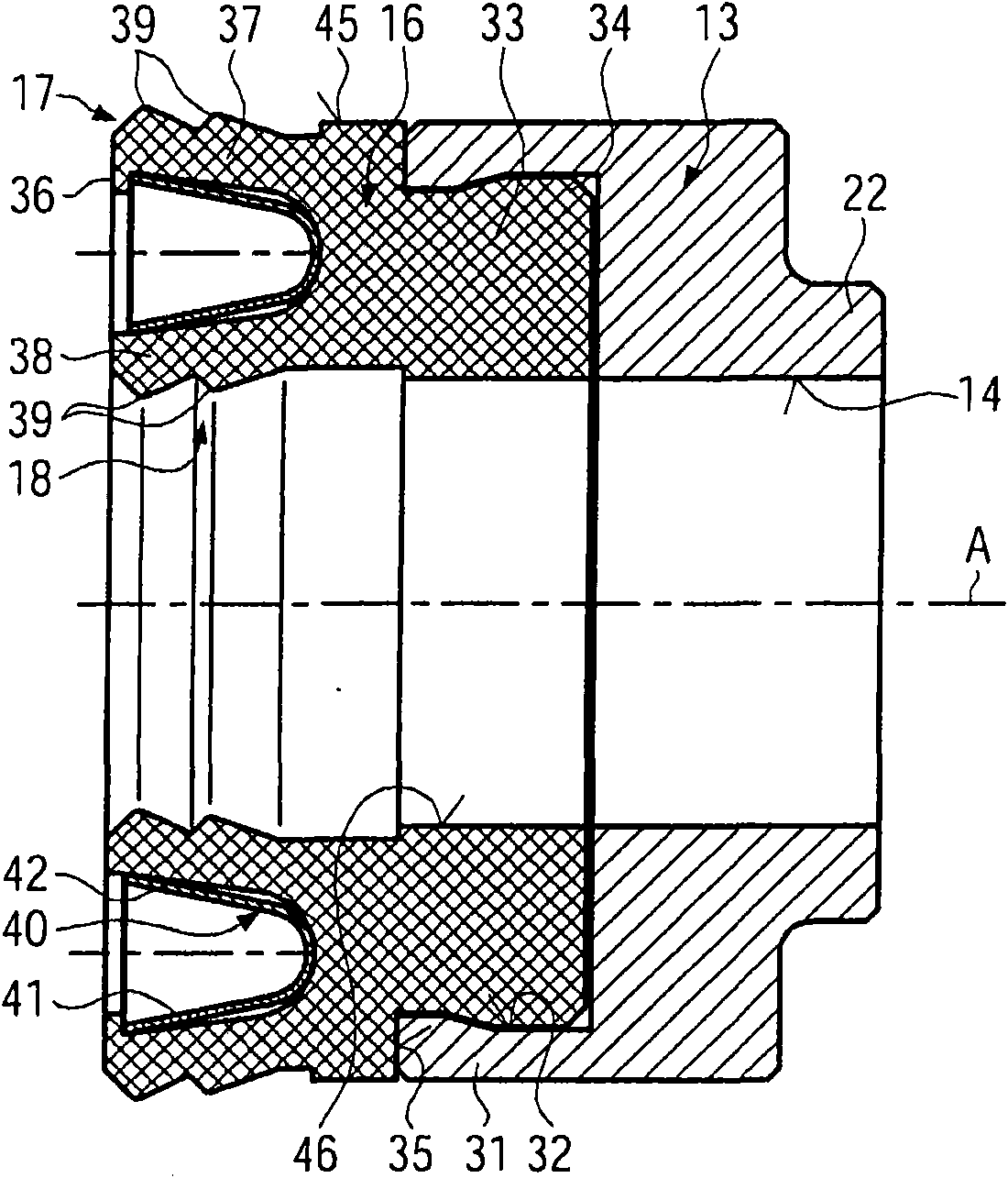

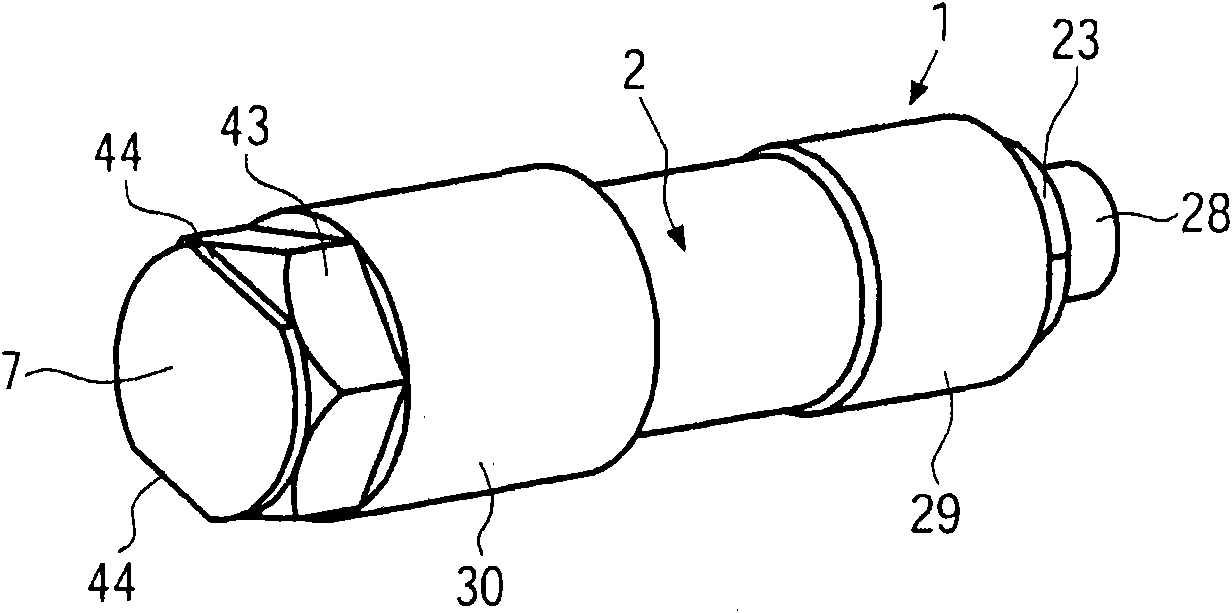

[0022] figure 1 A hydraulic self-contained automatic tensioner 1 is shown for a timing chain drive or an auxiliary unit drive of an internal combustion engine, the tensioner 1 comprising a hollow cylindrical housing 2 in which a tensioning plunger 3 is held The guidance is such that it is longitudinally displaceable along the axis A in the plunger bore 4 of the housing. The tensioning plunger 3 comprises a plunger bottom 5 through which the tensioning plunger 3 is guided in the plunger hole 4 and the plunger rod 6 follows said plunger bottom 5 across in the direction of tensioning and extension. At the end face of the housing 2 on the tensioning side of the hydraulic tensioner 1 , a pretensioning can be applied to the adjoining chain drive. On the installation side of the hydraulic tensioner 1, that is, on the side facing away from the tensioning side, an end plug 7 is arranged in an opening on the end face of the hollow cylindrical shell 2, and the end plug 7 passes through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com