Method and device for process temperature control by means of a heat pump in a material preparation cycle

A preparation process, temperature control technology, applied in heat recovery systems, energy-saving heating/cooling, and removal of fat/resin/asphalt/wax from pulp, etc., can solve problems such as decreased separation rate of sticky dirt, and achieve a small tendency to stick , energy saving, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

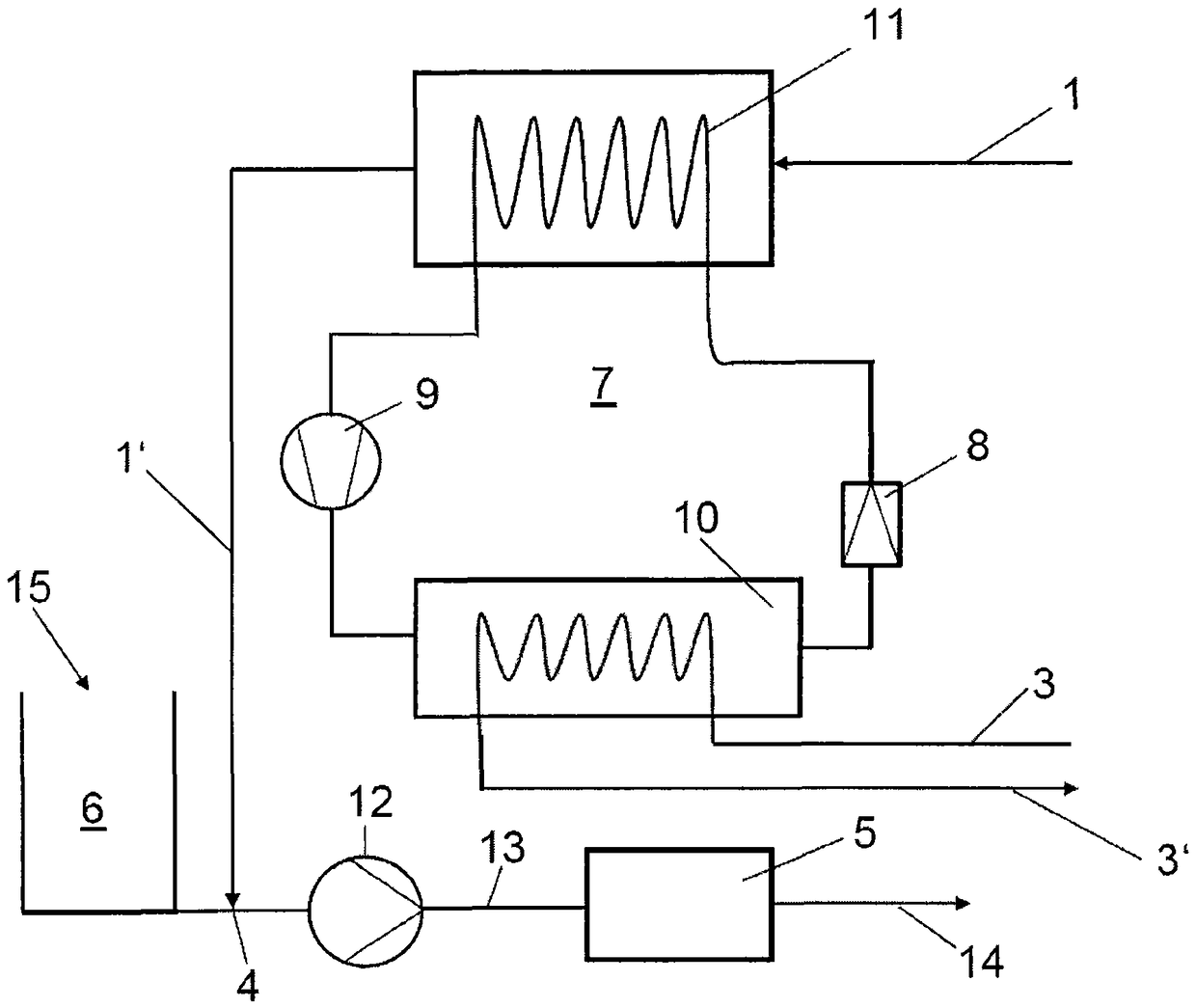

[0017] In this case, fibrous material 15 , such as waste paper, is introduced into the material separator 6 and the fibrous material 15 is disintegrated therein. The dissociated fibrous material flow 13 is then introduced by means of a pump 12 into a sorting system 5 in order to separate contaminants, with particular attention to sticky contaminants. The sorting system essentially consists of several, but at least one, so-called pressure classifier stages, which are provided with rotors and screen baskets. The aim is to achieve the greatest possible sorting accuracy between the pollutants (in particular viscous soils) and the fibrous material. Here, as much fiber as possible should pass through the screen basket as so-called good material. The cleaned good material stream 14 of the sorting system 5 can then be passed on to further process steps.

[0018] Cooled dilution water (filtrate) 1' is added to the fibrous material suspension prior to the sorting process via dilution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com