Sealing structure of shaft end of horizontal concrete mixer

A concrete mixer and shaft end sealing technology, which is applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of high circumferential rotation speed, damage to floating ring seals, and oil spillage, etc., so as to improve the service life , Guaranteed sealing effect, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

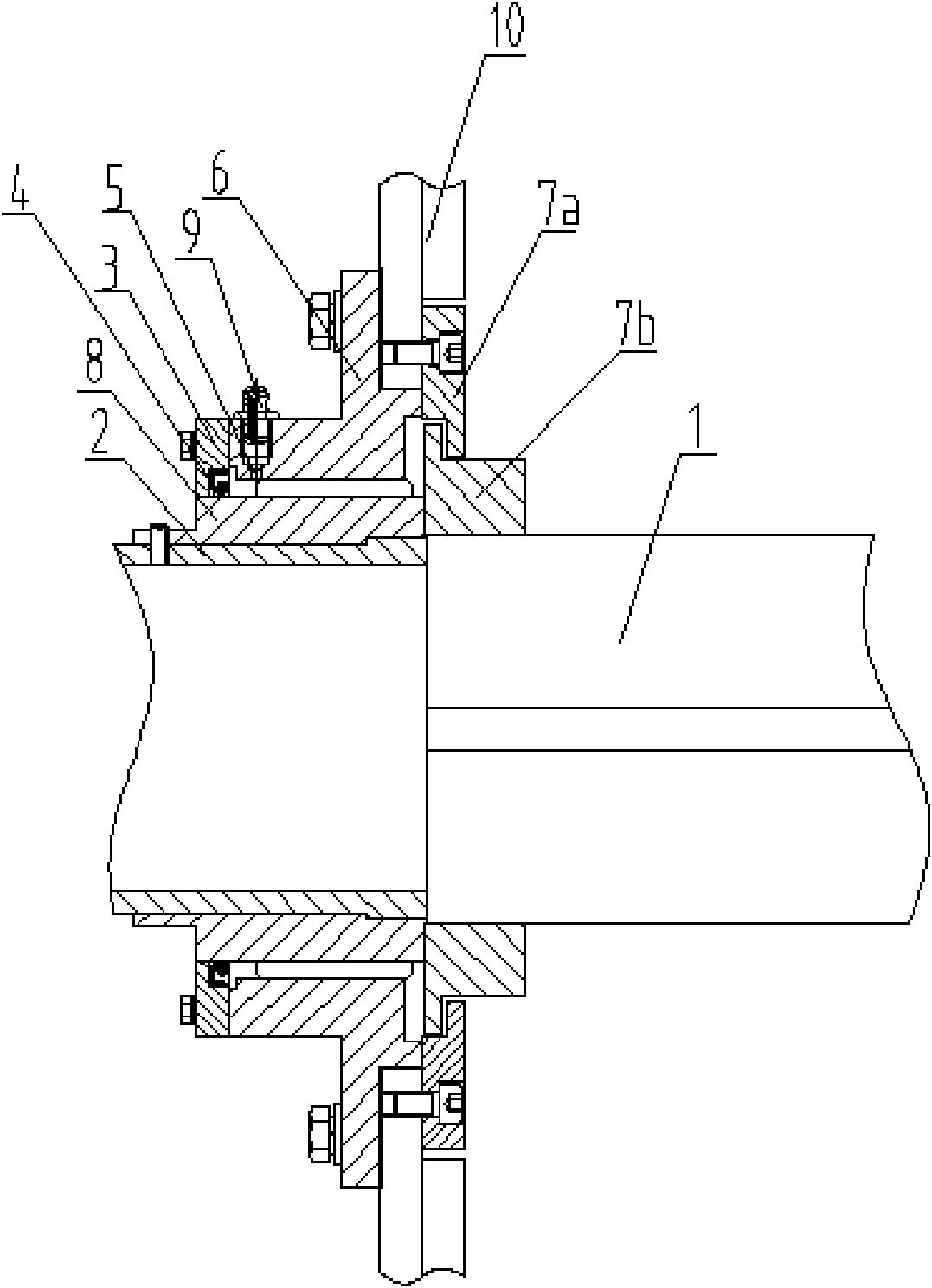

[0023] Example: as figure 1 Shown: a shaft end sealing structure of a horizontal concrete mixer, comprising a main shaft 1, a mixer shell 10, a shaft sleeve 2 fixed on the outer ring of the main shaft 1, and a spiral body 8 fixed on the outer ring of the shaft sleeve 2 , the spiral body 8 is sheathed with an "L"-shaped sealing jacket 6 in cross-section, and a spiral channel is formed between one side of the "L"-shaped sealing jacket and the spiral body 8, and the other side is attached to the mixer On the outer wall of the housing 10, an oil inlet hole 5 is opened on the sealing outer casing 6, and an end cover 3 is provided on the outer end surface of the sealing outer casing 6. The outer end opening of the mixer shell 2 is closed; a first wear-resistant block 7a is fixed on the inner wall of the mixer shell 2, and a second wear-resistant block 7b is arranged below the first wear-resistant block 7a. A labyrinth seal is formed between the two wear-resistant blocks 7b, wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com