Electric heating fused cleaning device for modulating wave oil tubes and sucker rods

A sucker rod and modulated wave technology, used in isolation devices, cleaning appliances, wellbore/well components, etc., can solve the problems of increased pipe washing time and cost, large floor space, and easy generation of pollution along the way.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

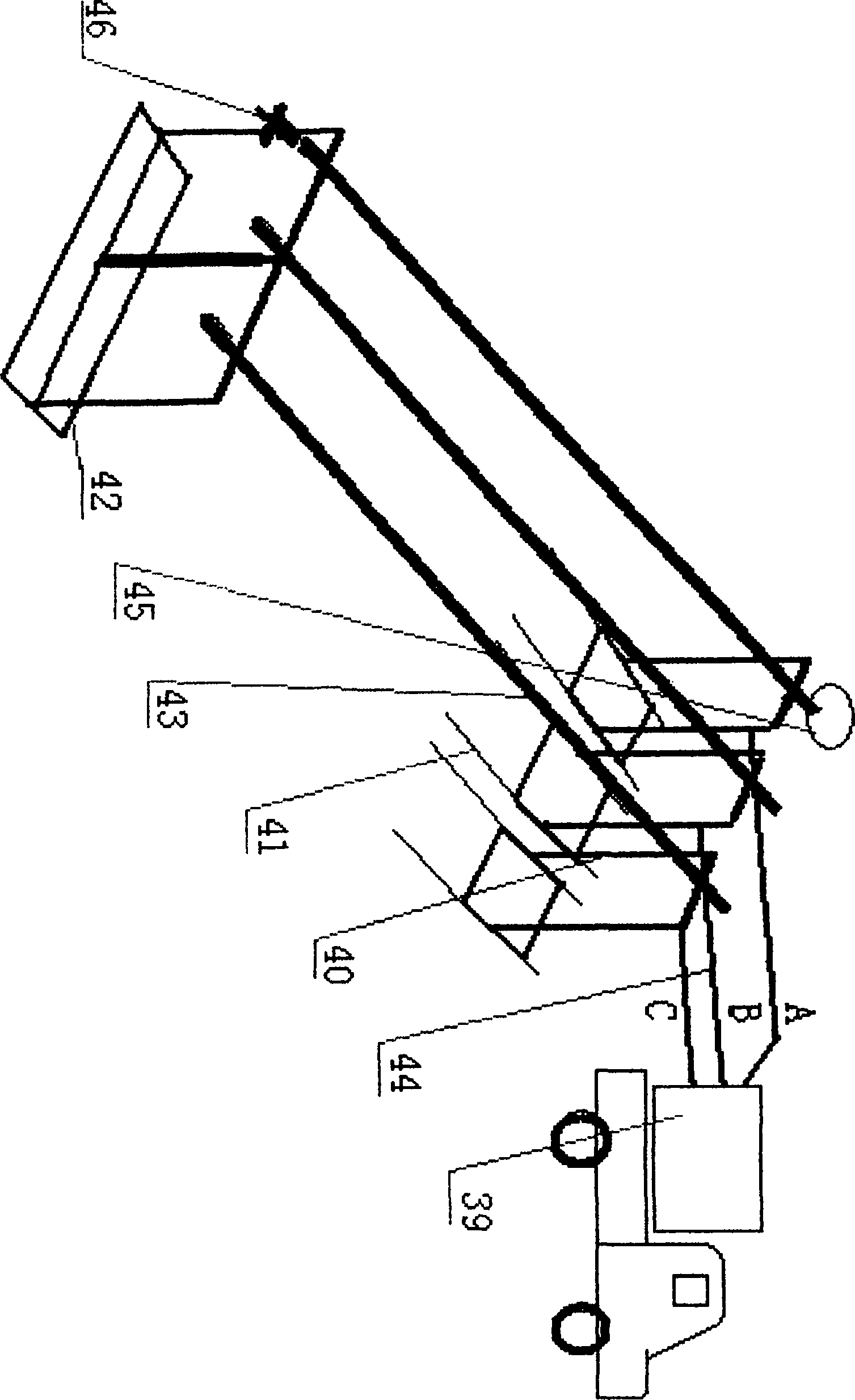

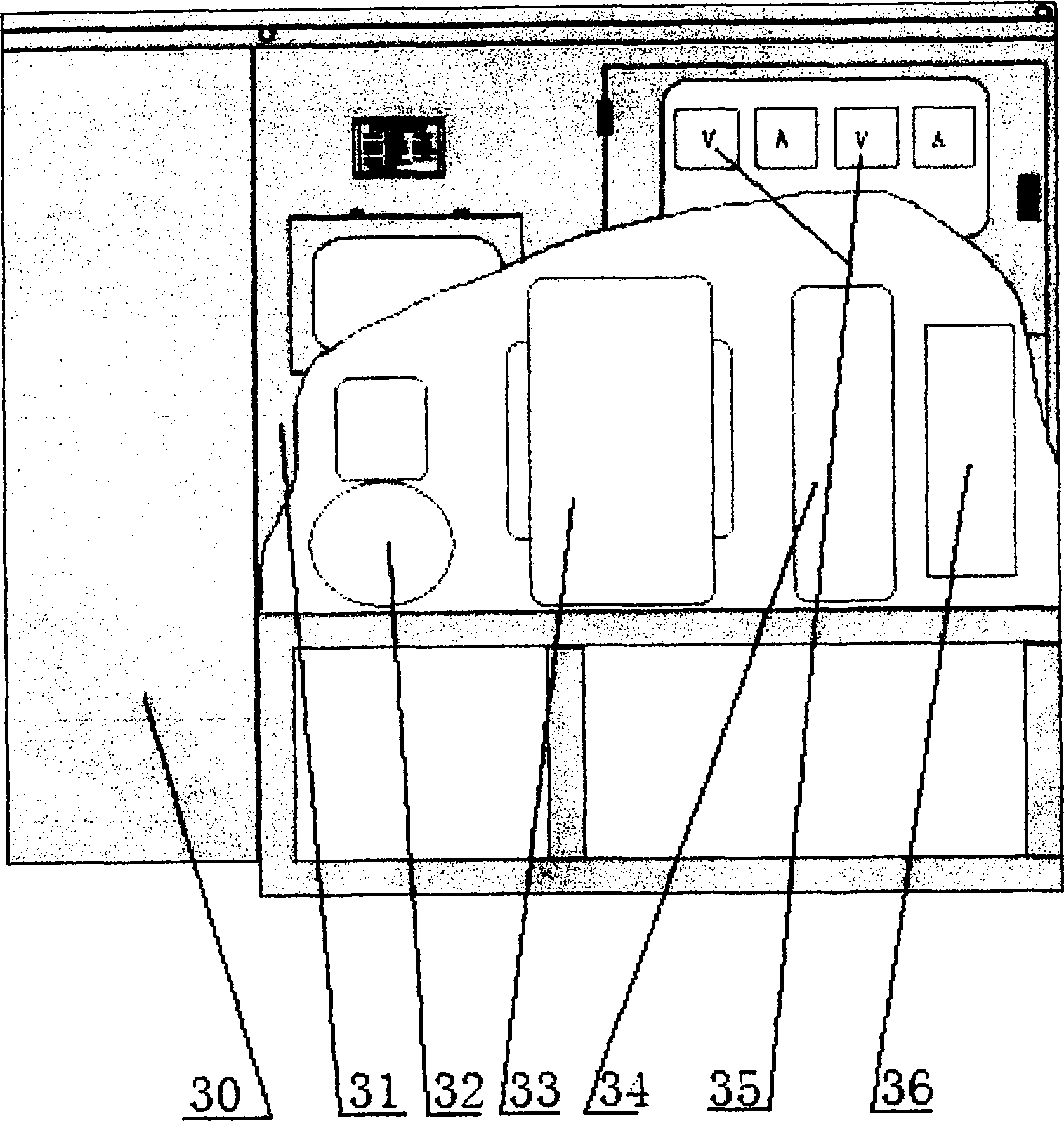

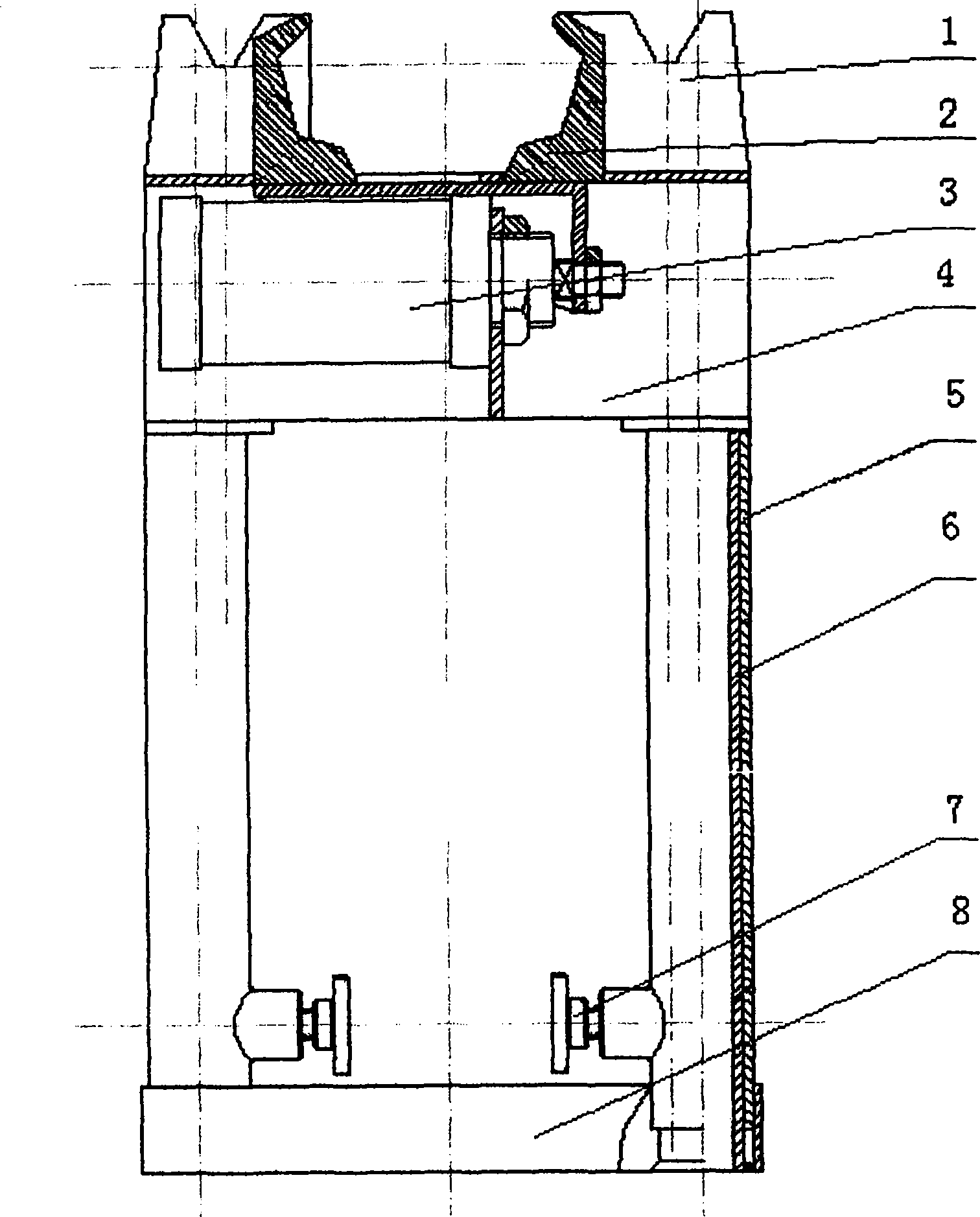

[0012]A further description of the electric heating melting washing device for modulated wave oil pipe and sucker rod of the present invention: an electric heating melting washing device for modulated wave oil pipe and sucker rod, the device is mainly composed of a vehicle-mounted wave modulating power supply, a pneumatic electrode clamp frame, an electrode clamp frame guide rail, pneumatic lifting electric clamp frame, pneumatic pipe cleaner, crude oil recovery device, air control circuit and primary and secondary power supply circuits; The phase power frequency alternating current is automatically converted into a three-phase modulated wave current lower than 36V, and is respectively connected to the terminals of the three electrode clamps 40 of A, B, and C by the secondary cables 44, and the pneumatic lift clamp 42 connects the three poles The oil pipe 43 as an electrothermal converter forms a good electrical connection, and uses it as the middle phase of the Y-shaped circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com