Intake manifold

A technology of intake manifold and intake pipe, which is applied in combustion air/combustion-air treatment, engine components, machine/engine, etc. Problems such as poor performance to achieve the effect of improving allocation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

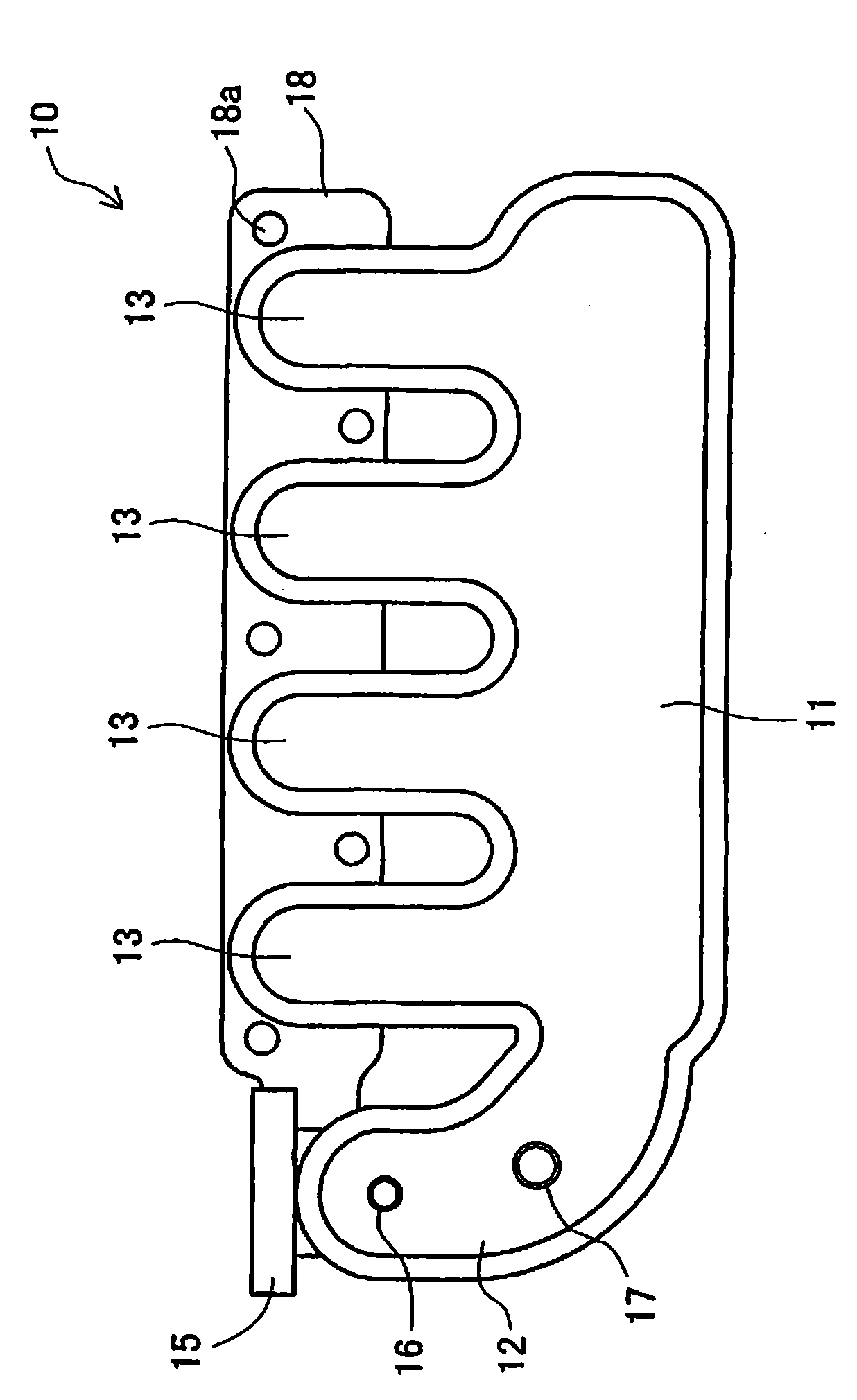

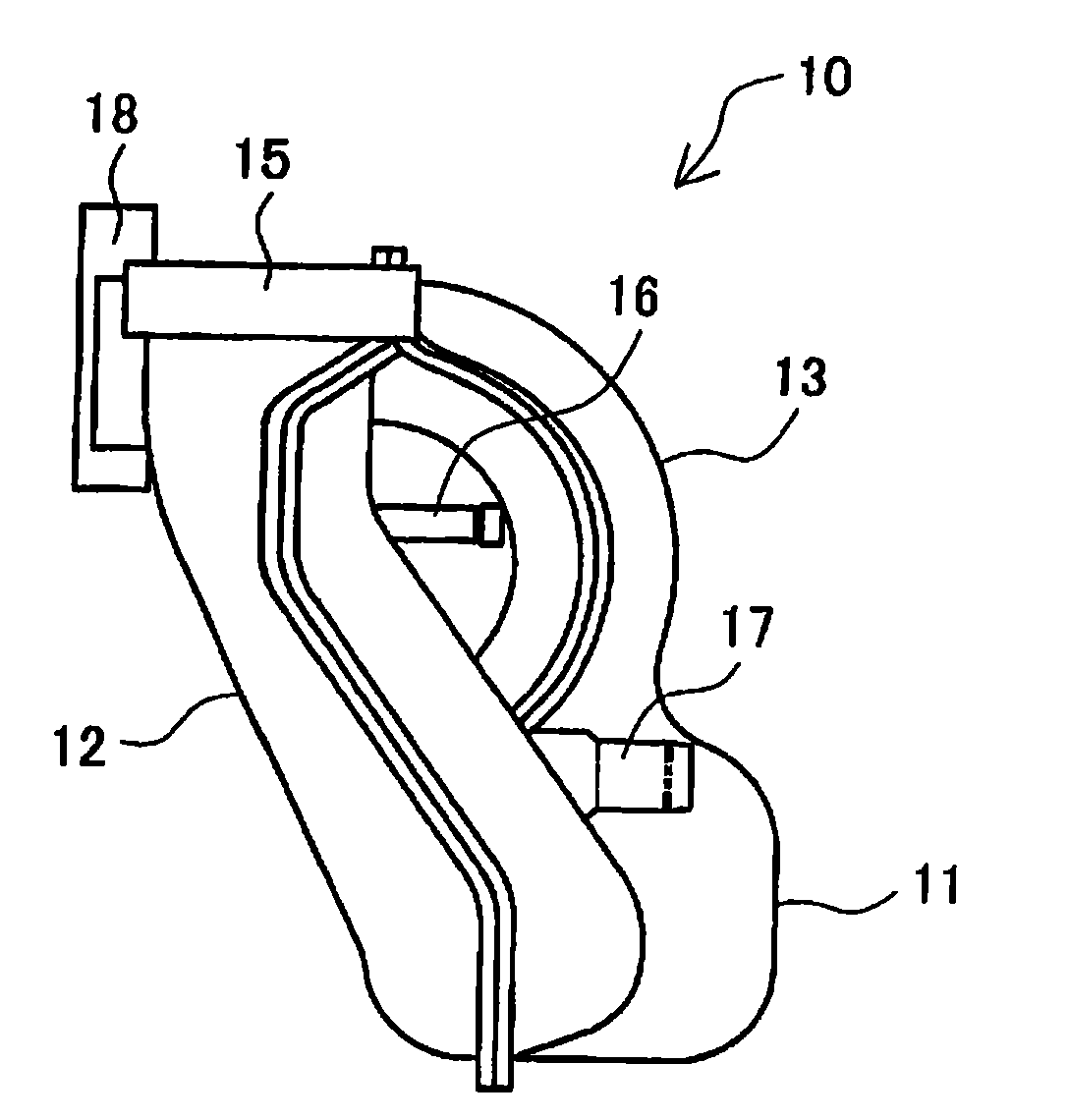

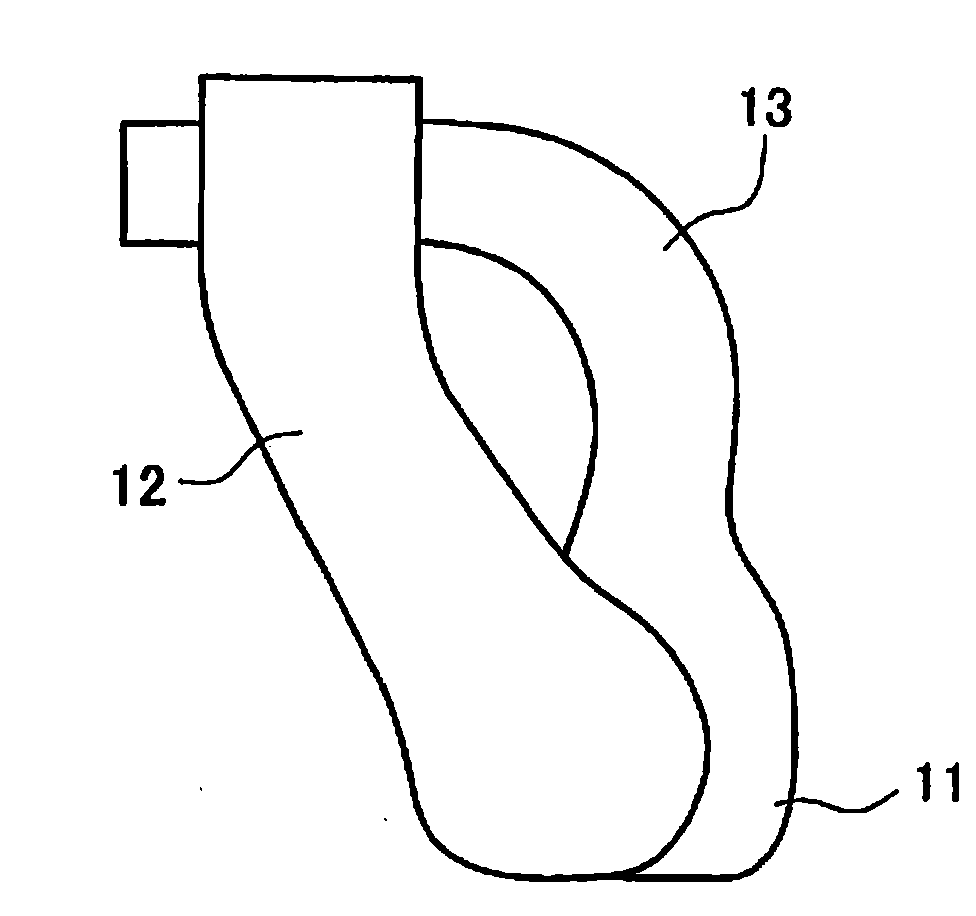

[0031] Hereinafter, the best mode for realizing the intake manifold of the present invention will be described in detail based on the drawings. In this embodiment, a case where the present invention is applied to an intake manifold used in an intake system of a 4-cylinder gasoline engine will be described.

[0032] Here, refer to Figure 1 ~ Figure 3 The intake manifold of this embodiment will be described. figure 1 It is a front view showing a schematic structure of the intake manifold of the embodiment. figure 2 It is a side view showing the schematic structure of the intake manifold of the embodiment. image 3 It is a figure which schematically shows the duct space formed in the intake manifold of embodiment.

[0033] Such as figure 1 , figure 2 As shown, the intake manifold 10 includes a surge tank 11 , an air intake pipe 12 and four air intake branch pipes 13 . The intake manifold 10 is a resin intake manifold called a resin intake manifold, and supplies air (inta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com