Light guide plate and backlight module

A technology of a backlight module and a light guide plate, applied in the field of light guide plates, can solve the problems of insufficient light intensity, influence of sign display effect, high manufacturing cost, and achieve the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

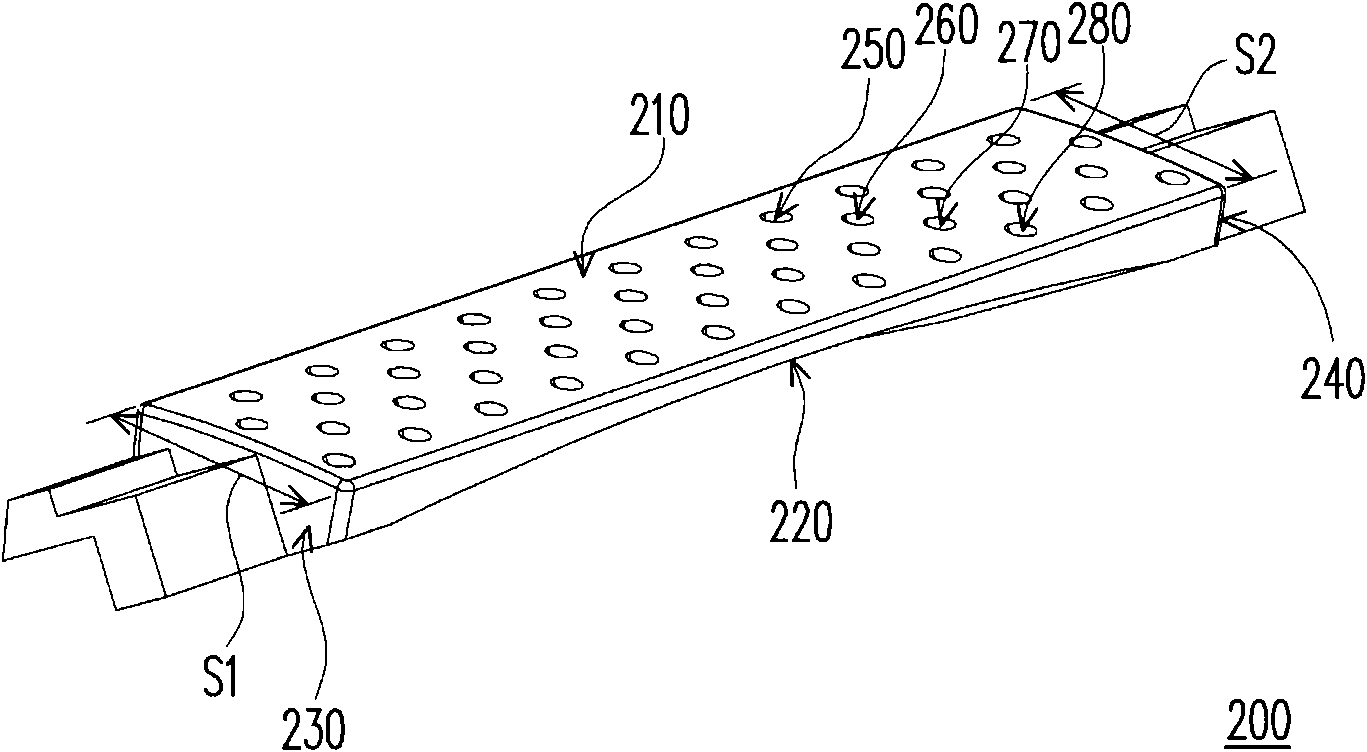

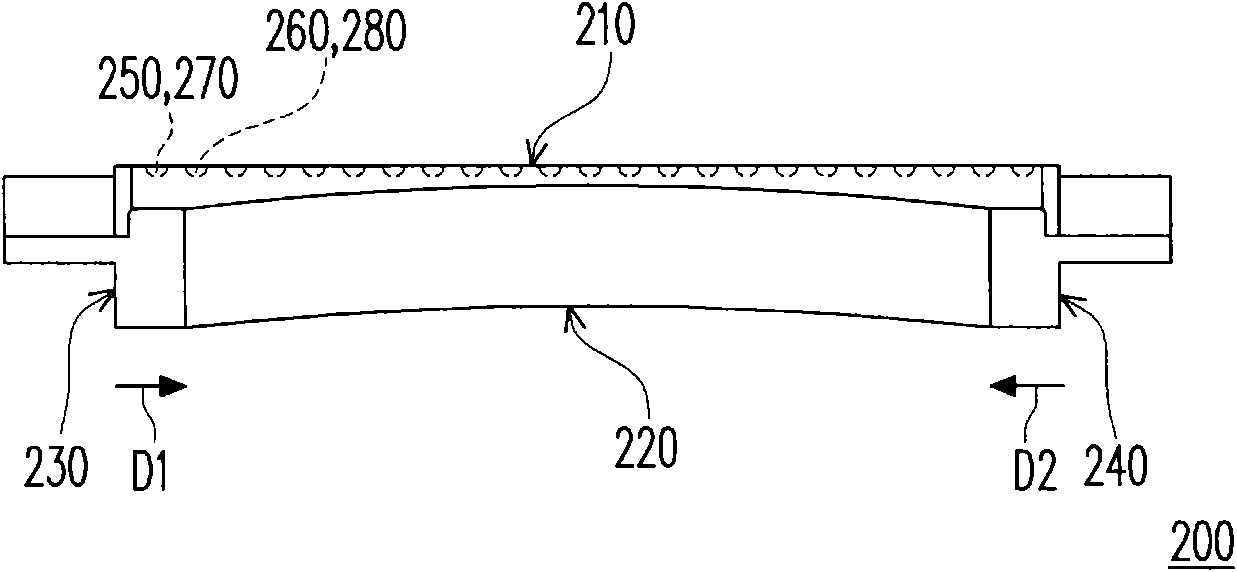

[0057] Figure 2A A three-dimensional schematic view of a light guide plate according to an embodiment of the present invention is shown, Figure 2B draw Figure 2A The side schematic diagram of the light guide plate, Figure 2C draw Figure 2A A partial top view schematic diagram of the light guide plate. Please also refer to 2A, Figure 2B and Figure 2C The light guide plate 200 in this embodiment has a light-emitting surface 210, a bottom surface 220 opposite to the light-emitting surface 210, and a first light-incident surface 230 and a second light-incident surface that connect the light-emitting surface 210 and the bottom surface 220 and are opposite to each other. 240. In this embodiment, the material of the light guide plate 200 is, for example, polymethylmethacrylate (PMMA) or polycarbonate (polycarbonate, PC), and is formed by injection molding.

[0058] The bottom surface 220 gradually approaches the light emitting surface 210 along a first direction D1 away f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com