Recovery device for condensed water

A recovery device and condensed water technology, which is applied in the direction of drying solid materials, lighting and heating equipment, drying, etc., to achieve the effect of simple and reliable device, reduce load and improve drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

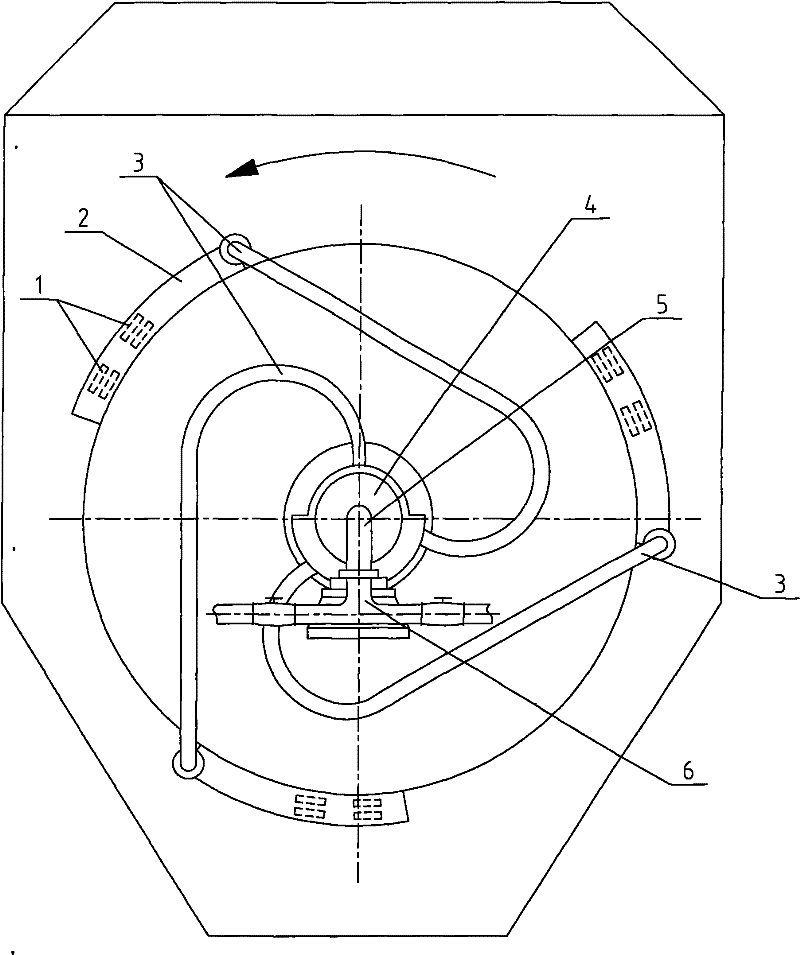

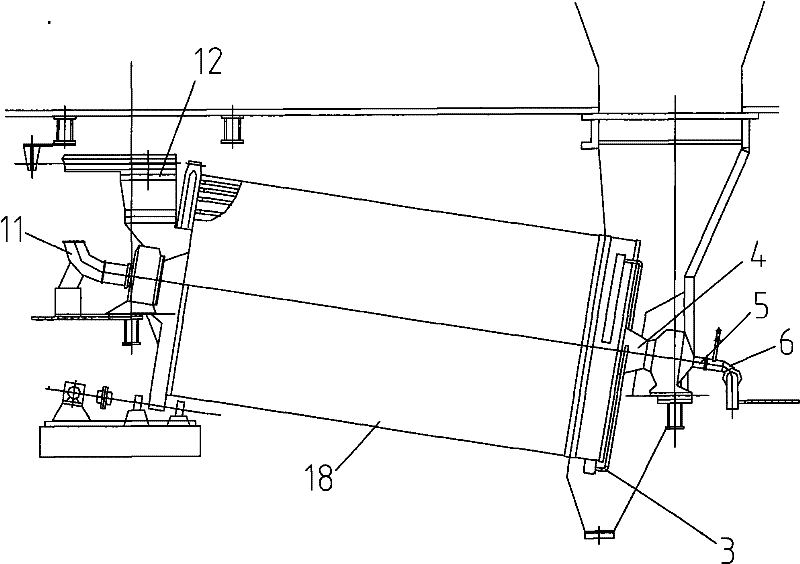

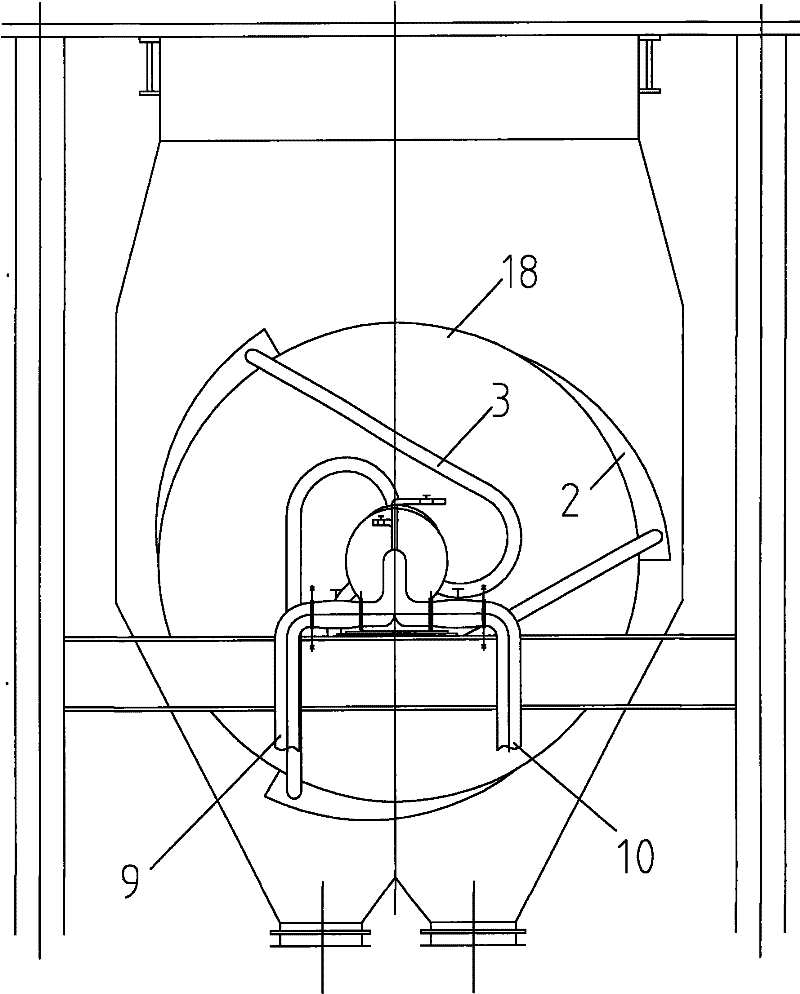

[0054] Such as Figures 1 to 5 As shown, the condensed water recovery device of the present invention is arranged at the precipitation end of the inclined pipe dryer drum 18, connected to the cast steel journal 4 of the dryer drum 18 and the shaft seal pipe 5 communicated with the cast steel journal 4 , consists of three groups of dip tubes set at the precipitation end of the dryer drum 18 at intervals of 120 degrees and an outflow pipeline capable of adjusting the air pressure. The injection end of the inclined tube dryer drum 18 includes a central live steam pipeline 11 and a material inlet 12 .

[0055] The dip tube set comprises two outflow holes 1 , a collection tank 2 and a dip tube 3 . The outflow hole 1 ring is set on the cylinder wall of the dryer cylinder 18 at the precipitation end. The collection tank 2 is arranged on the outer wall of the precipitation end of the dryer drum 18 and communicates with the outflow hole 1 . One end of the dipping elbow 3 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com