Tunnel water seepage and harmful gas discharge structure and construction method of semi-closed ice-filled drilling

A harmful gas and construction method technology, applied in tunnels, tunnel linings, drainage, etc., can solve problems such as difficult separation of harmful gases from water, unsatisfactory negative pressure formation, and high operational safety risks, achieving continuous drainage, Guaranteed continuous drainage and low construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

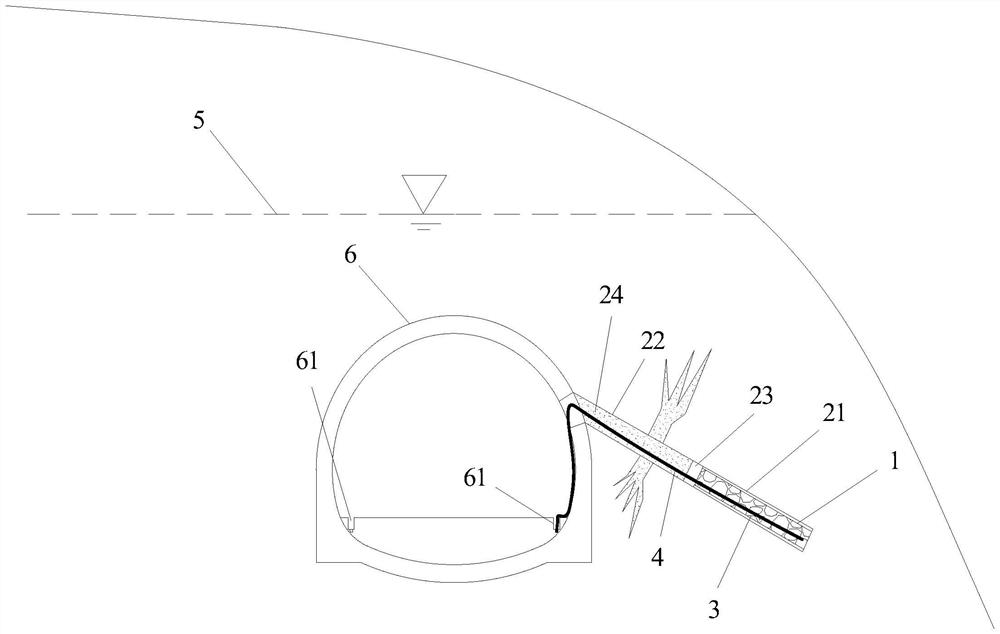

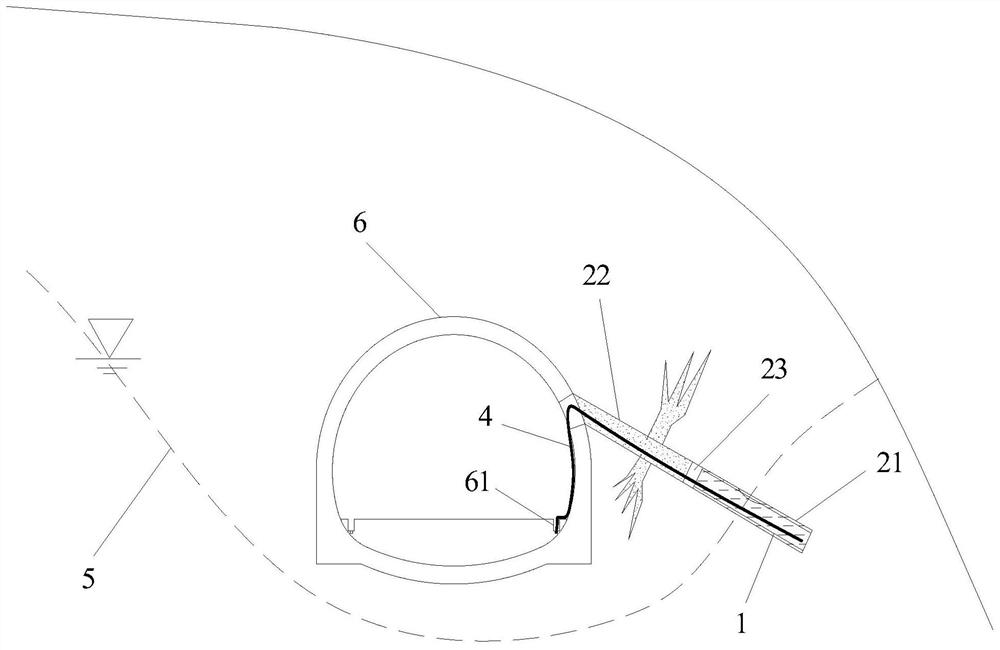

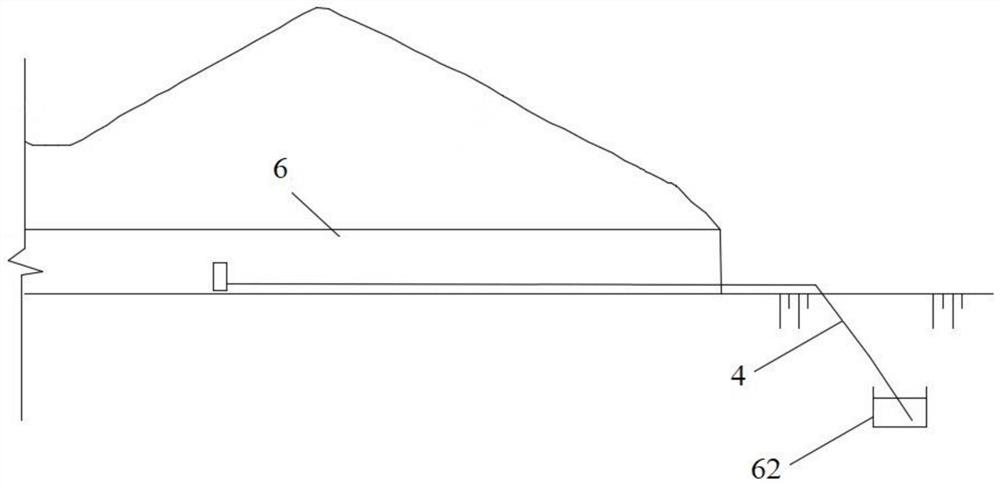

[0040] Such as figure 1 As shown, the tunnel 6 has no requirement for the discharge of harmful gases, and is mainly aimed at water seepage control. A tunnel water seepage and harmful gas discharge structure according to the present invention includes a water permeable pipe 1, and the water permeable pipe 1 is arranged in the water permeable section of the borehole In 21, the position of the borehole is determined according to the position of the water seepage point. It is drilled from the side wall of the tunnel 6 with an inclination. The inclination angle between the borehole and the horizontal plane is 5-10°. As with the grouting section 22, the length of the grouting section 22 is the same as the thickness of the lining concrete of the tunnel 6, and the length of the permeable section 21 is, for example, 5-10m, if the thickness of the lining concrete of the tunnel 6 is uncertain , the length of the grouting section 22 is 0.5-0.6m. A water-stop member 23 is set between the ...

Embodiment 2

[0047] A kind of semi-enclosed ice-filled drilling construction method according to the present invention adopts the discharge structure as described in Embodiment 1, and comprises the following steps:

[0048] a. According to the position and range of the water seepage point on the side wall of the tunnel 6 and the escape point of harmful gas (if any), correspondingly drill downwardly inclined boreholes;

[0049] b. Set a permeable pipe 1 in the permeable section 21 of the borehole, and then insert a drain pipe 4 into the permeable pipe 1, so that the port of the drain pipe 4 goes deep into the bottom of the permeable pipe 1;

[0050] c. Fill the permeable pipe 1 with ice cubes 3 and compact it, and then install a water-stop member 23 to block the permeable section 21;

[0051] d, inject slurry 24 into the borehole to form a grouting section 22, and complete the construction of the discharge structure; the grouting pressure can be increased during grouting, and the slurry 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com