Fixed electrode of sliding welding machine

A technology of fixed electrode and sliding welding, applied in the direction of roller electrode welding, etc., can solve the problems of increased manufacturing cost, inconvenience, and high cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

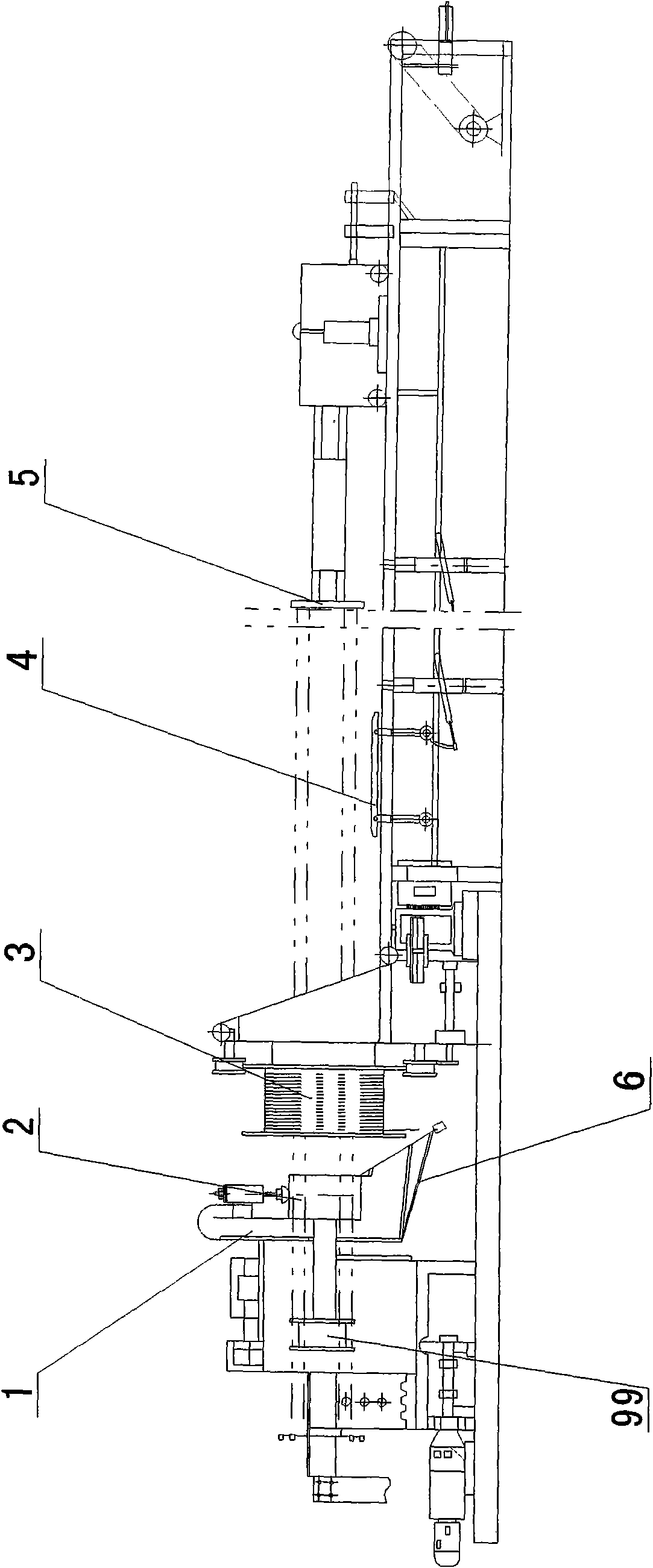

[0035] figure 1 A sliding welding device is shown, which includes an electrode wheel 1, a fixed electrode 2, a movable electrode, a longitudinal tendon traction disc 5, a fixed rib guide disc 99, a stirrup disc 3, a stirrup winding mechanism 6, and a metal cage transmission mechanism 4.

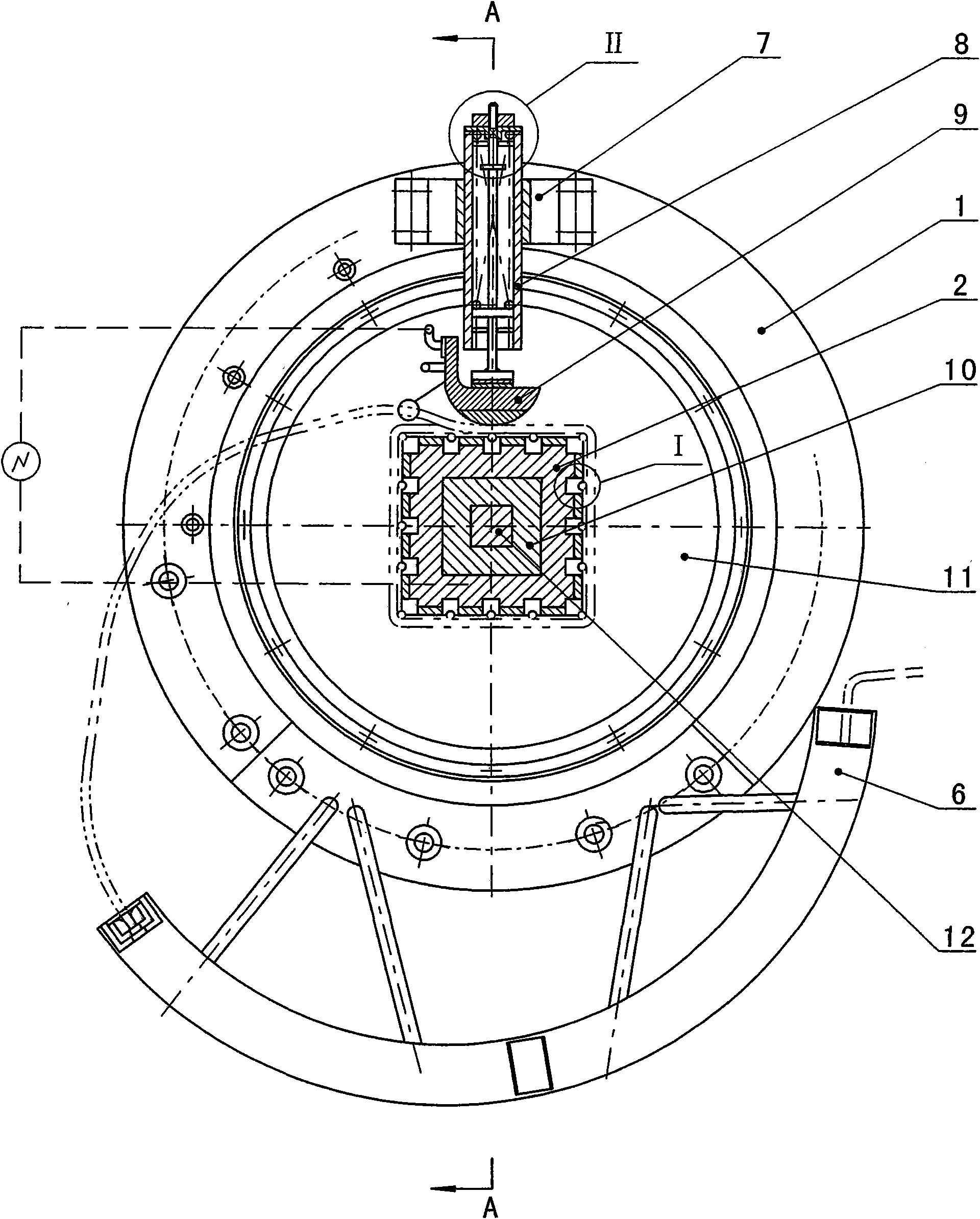

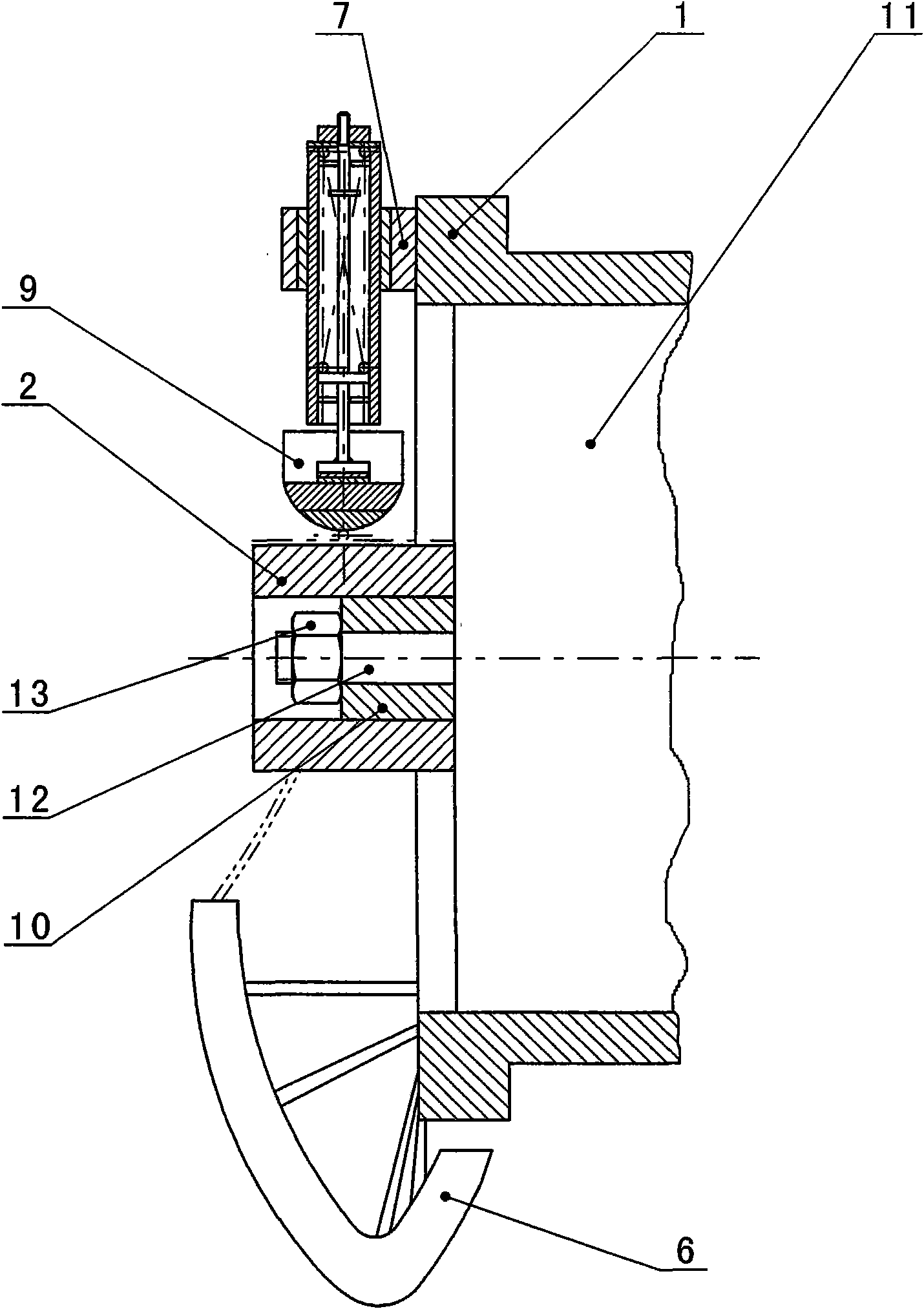

[0036] figure 2 Among them, the fixed electrode 2 is a square, and the outer surface of the fixed electrode 2 is provided with a number of grooves along the axial direction. The movable electrode has elastic movement along the radial direction of the fixed electrode 2, circumferential movement along the center of the fixed electrode 2, The electrode body 9 sliding on the outer side of the stirrup. The electrode body 9 is at the contact point between a longitudinal rib and the stirrup in the middle of one side of the fixed electrode 2, and the electrode body 9 is at the lowest position. The electrode body 9, longitudinal rib, stirrup and fixed electrode 2 shown in the figure are in the lead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com