High-flatness integrative solar power generation integral roof and installation method thereof

A solar cell and flatness technology, applied in the direction of roofs, photovoltaic power generation, optical radiation generators, etc., can solve the problems of poor waterproofness, high cost, easy water leakage, etc., achieve excellent waterproof and anti-seepage performance, save costs and materials , the effect of simple installation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

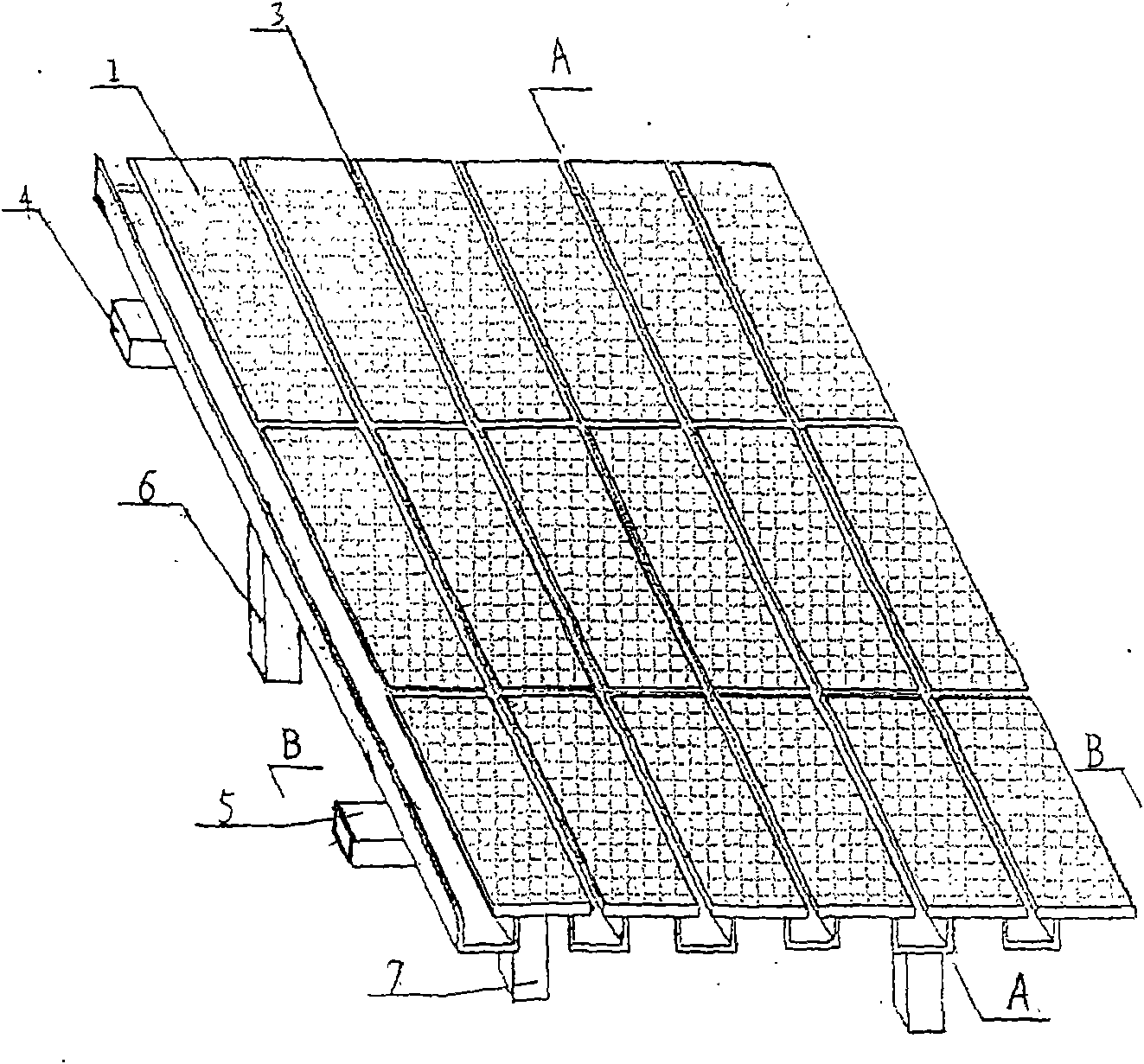

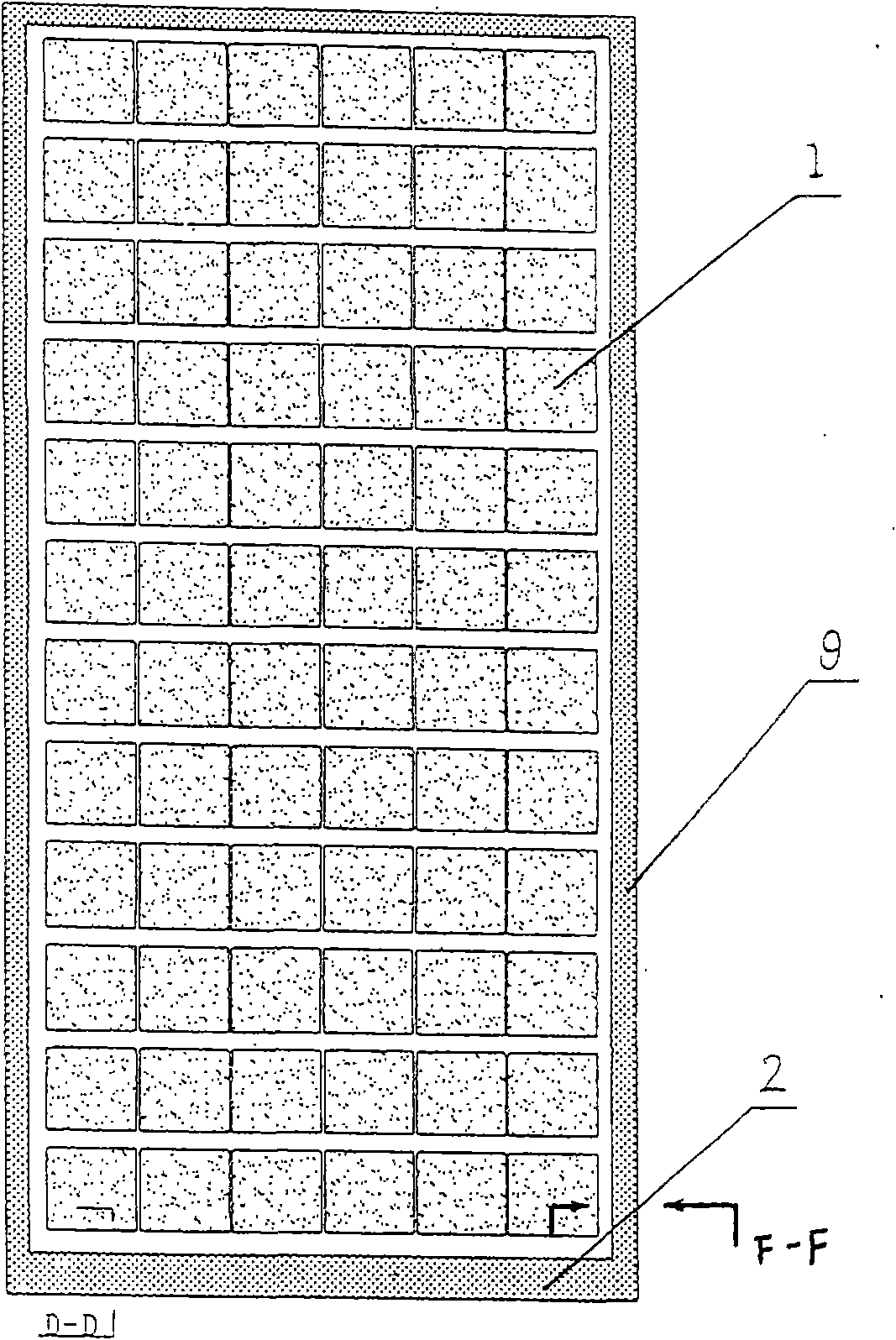

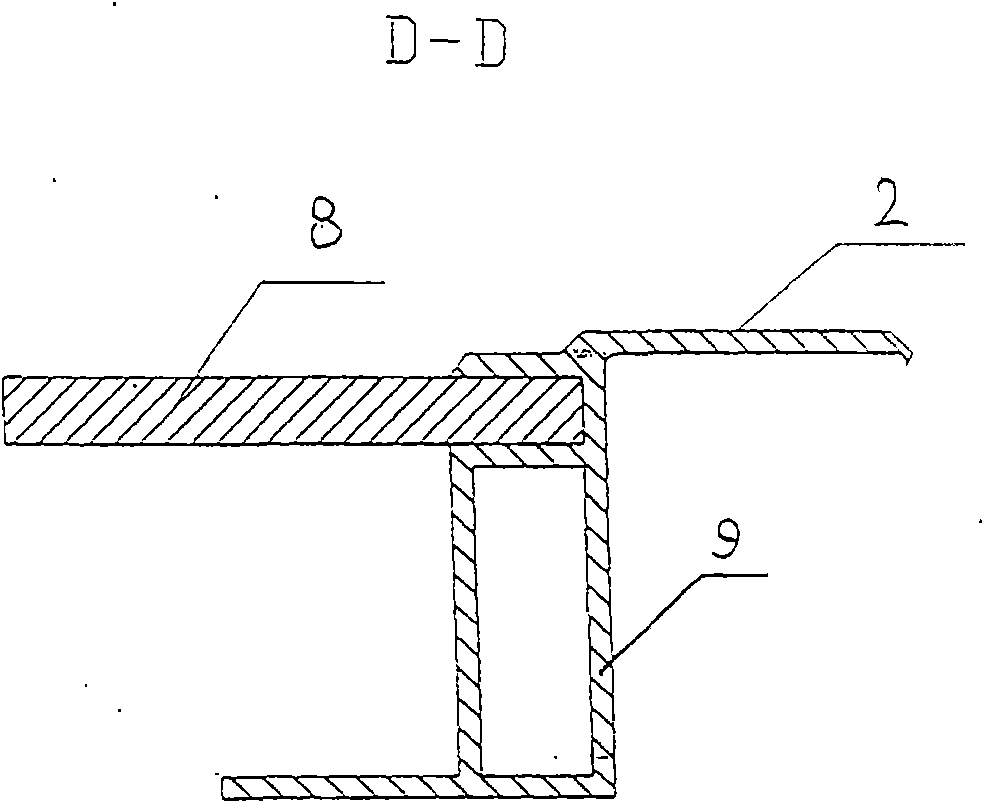

[0025] The present invention is described below in conjunction with accompanying drawing:

[0026] First stack the solar cell modules 1 from bottom to top in an orderly manner, set the upper and lower frames of each solar cell module 1 in the positioning bayonet 16, and then place the frame under the side frame of each solar cell module The U-shaped groove 14 is fixed to the side of the U-shaped steel drainage groove with a pull rivet, and then the U-shaped steel drainage groove is fixed on the first purlin 4 and the second purlin 5 of the building roof, and the building supports the first column 6 and the second purlin of the roof. The front and rear heights of the two columns 7 are different to realize the required slope of the roof, and the cleaners can walk on the wide gutter of the roof to clean the dust and dirt through the safety ring provided by the safety guarantee belt hook. U-shaped grooves are arranged inside the side frame strips of the solar cell module 1 to faci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com