Warm edge insulating glass

A glass and hollow technology, applied in the direction of parallel glass structures, windows/doors, building components, etc., can solve the problems that the double-layer insulating glass cannot meet the needs and affect the heat insulation performance of the insulating glass edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

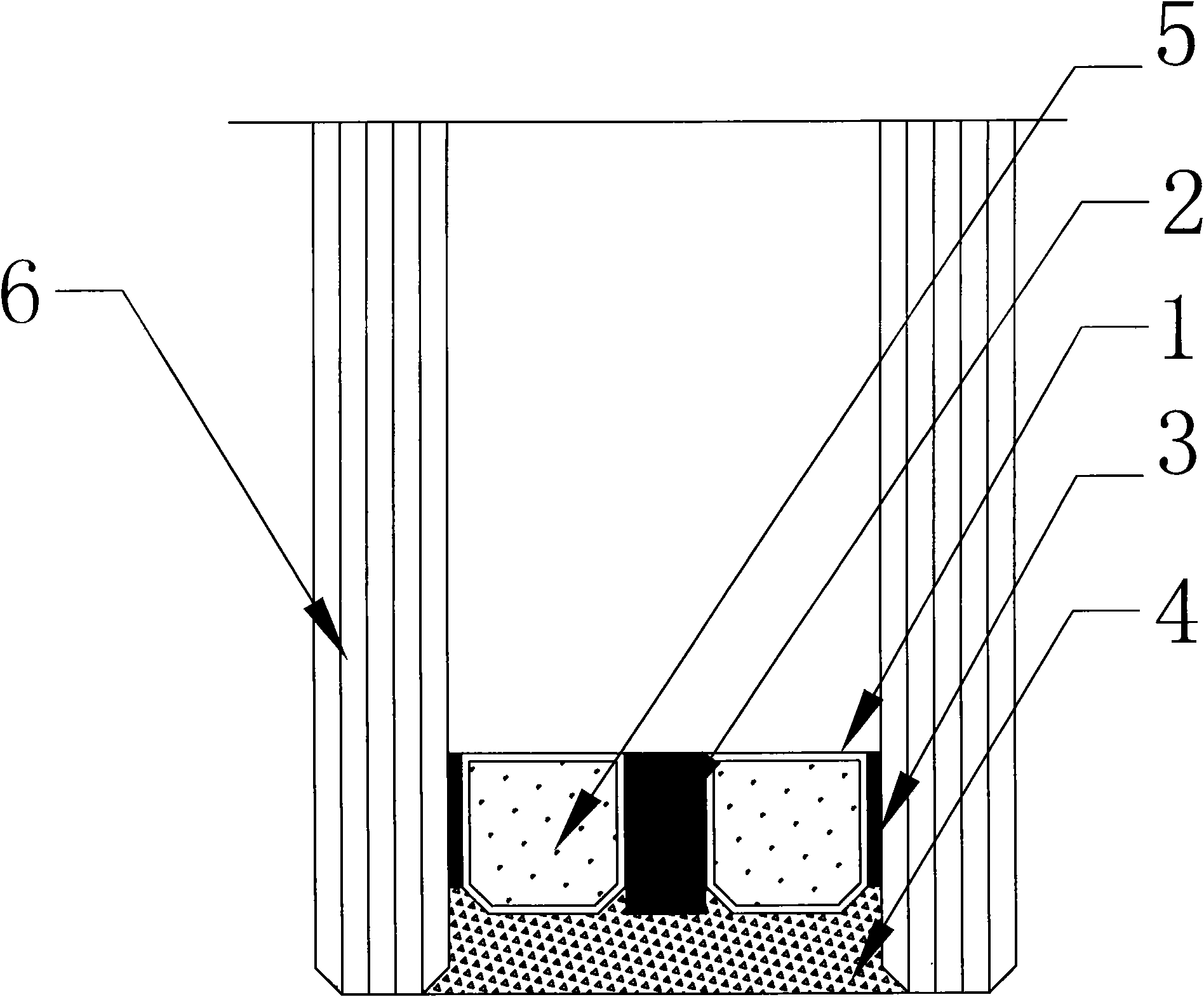

[0014] figure 1 It is a front cross-sectional view of the warm-edge insulating glass of the present invention. As shown in the figure, the present invention includes an insulating glass, which is composed of two parallel glass 6, and a hollow part is formed between the two glass 6. The hollow part is filled with glass sealant 4 to form a sealed hollow environment between two pieces of glass 6 . Two spacers 1 are arranged on the glass sealant 4 in parallel. Butyl glue 3 is filled between the spacer 1 and the glass 6 . Thus, the spacer 1 and the glass 6 are connected as a whole.

[0015] Reinforced polyethylene 2 is filled in the middle of the two spacers 1, and the two spacers 1 are bonded into a whole by the reinforced polyethylene 2. In addition to this function, because the reinforced polyethylene 2 has good heat insulation performance and sealing performance, the reinforced polyethylene 2 separates the two symmetrical spacers 1 to prevent excessive heat conduction.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com