Detection method of mine direct current method for coal face coal seam perspecitivity

A technology of coal mining face and direct current method, applied in mining equipment, mining equipment, measurement, etc., can solve the problem that high-frequency electromagnetic waves cannot effectively see through the coal mining face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

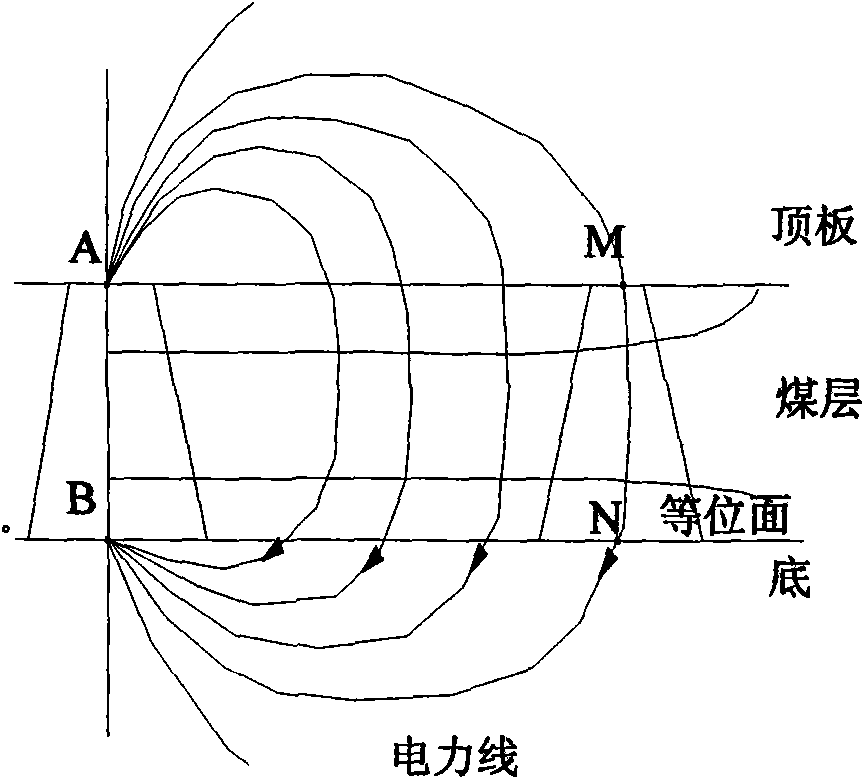

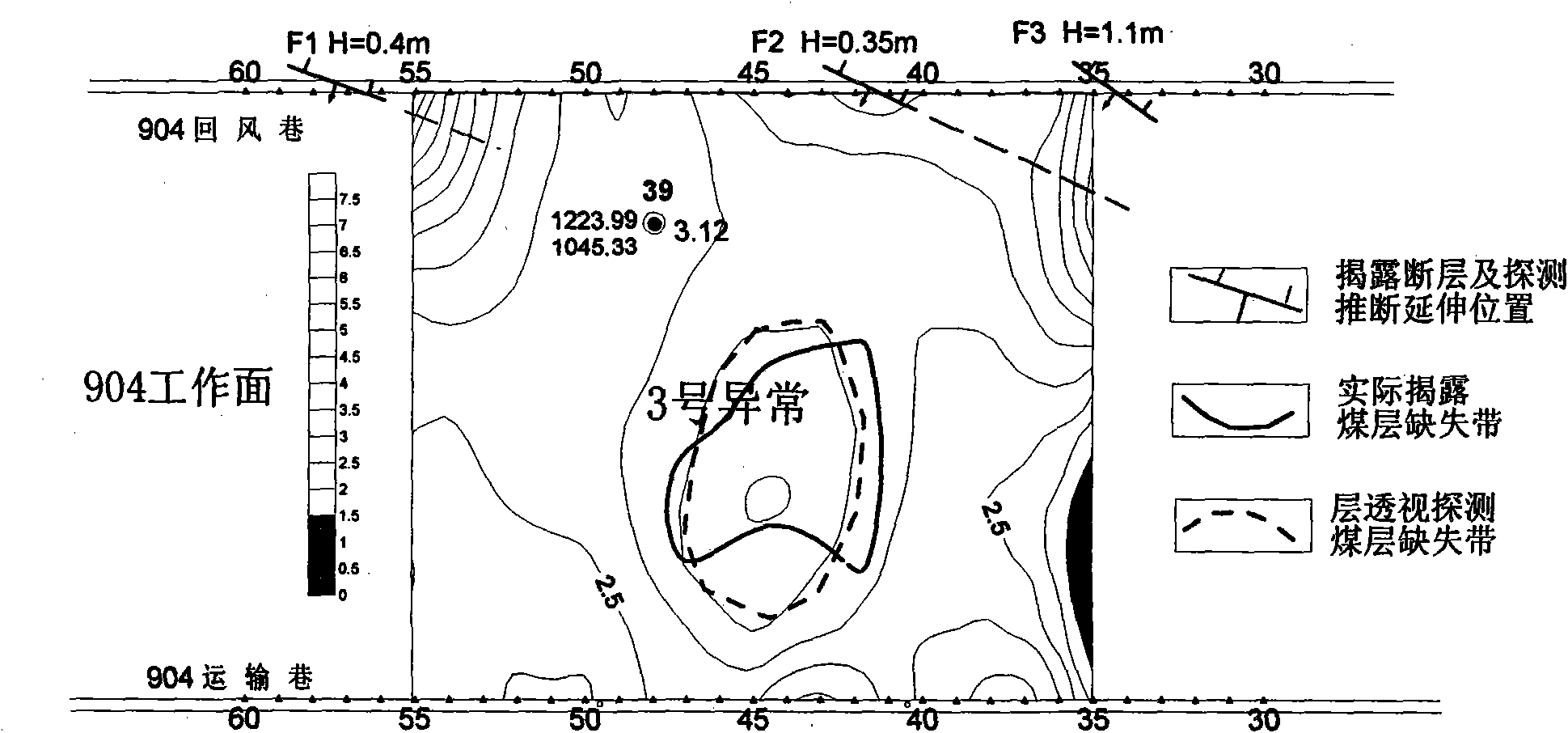

[0040] The direct current layer perspective detection method of the coal mining working face of the present invention belongs to the category of direct current method and adopts the direct current electric field detection theory; it does not have the coal seam and structure shielding effect in the working face when seeing through the working face along the coal seam, and there is no blind area, It can detect the coal-free zone and water-bearing water-conducting structure inside the coal seam of the coal mining face;

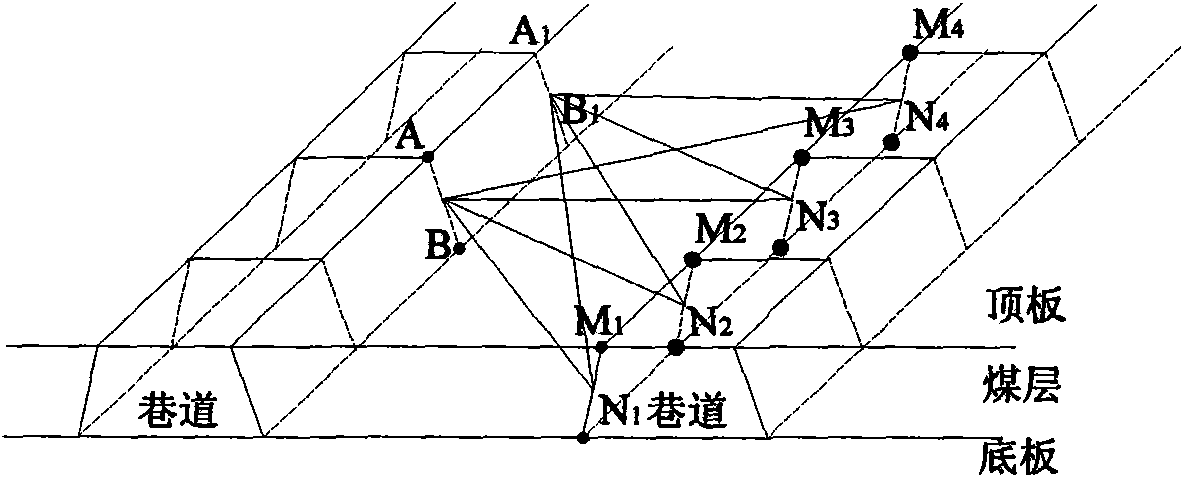

[0041] see figure 1 , figure 2 , one A mine direct current method detection method of coal mining face perspective along the coal seam, the power supply electrodes A and B are arranged along the two grooves of the working face, and a specific direct current electric field is established, so that the current line of the electric field is approximately perpendicular to the coal seam layer, and the equipotential plane is approximately parallel In the distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com