Multifunctional wet multi-disc brake

A kind of brake, multi-functional technology, applied in the direction of brake type, axial brake, brake components, etc., can solve the problems of insufficient softness, large braking impact, etc., to achieve the effect of good safety, easy maintenance, and soft braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

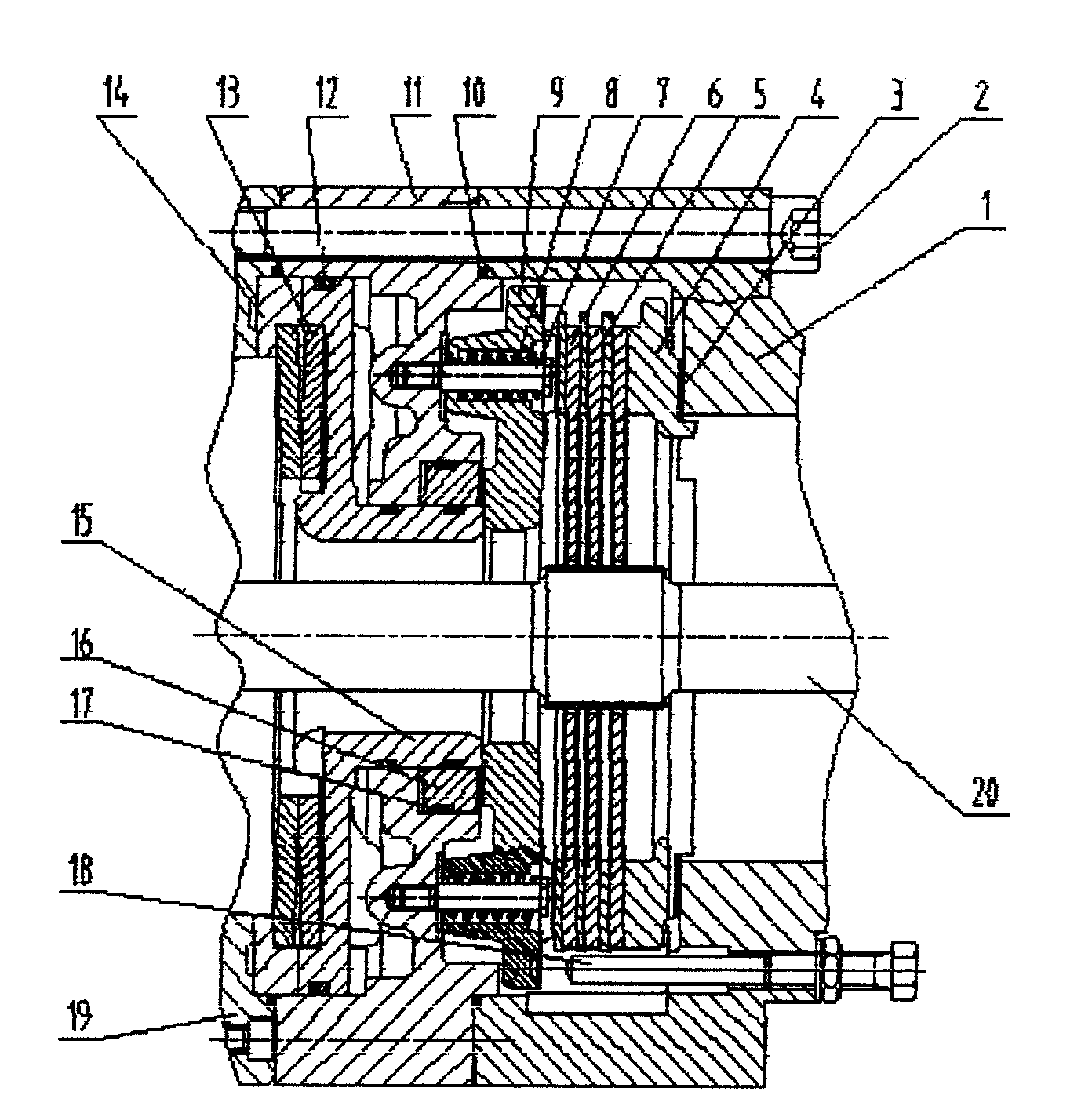

[0011] Such as figure 1 Shown: The main components of the wet multi-disc brake are: half shaft housing 1, housing connecting screw 2, adjusting gasket 3, pad 4, stator 5, friction plate 6, spring guide screw 7, compression spring 8, Pressure plate 9, seal ring 10, brake housing 11, parking brake piston seal ring 12, disc spring 13, disc spring seat 14, parking brake piston 15, service brake piston 16, service brake piston seal ring 17. Manually release the brake screw 18, the central housing 19, and the half shaft 20. The half shaft housing 1, the brake housing 11, the sealing ring 10 and the central housing 19 are connected as a whole by sixteen housing connecting screws 2 to form the inner cavity of the brake. The pressure plate 9 is located between the brake housing 11 and the friction plate 6, three sets of compression springs 8 are evenly spaced in the circumferential direction of the pressure plate 9, and the compression springs 8 are pushed against the inner end surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com