Method for assembling lighting tube connector

An assembly method and connector technology, which is applied in the direction of connection, connecting device connection/disconnection, discharge lamp, etc., can solve the problems of single-tube operation and large assembly space, and achieve improved assembly methods, reduced space, and smaller products The effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

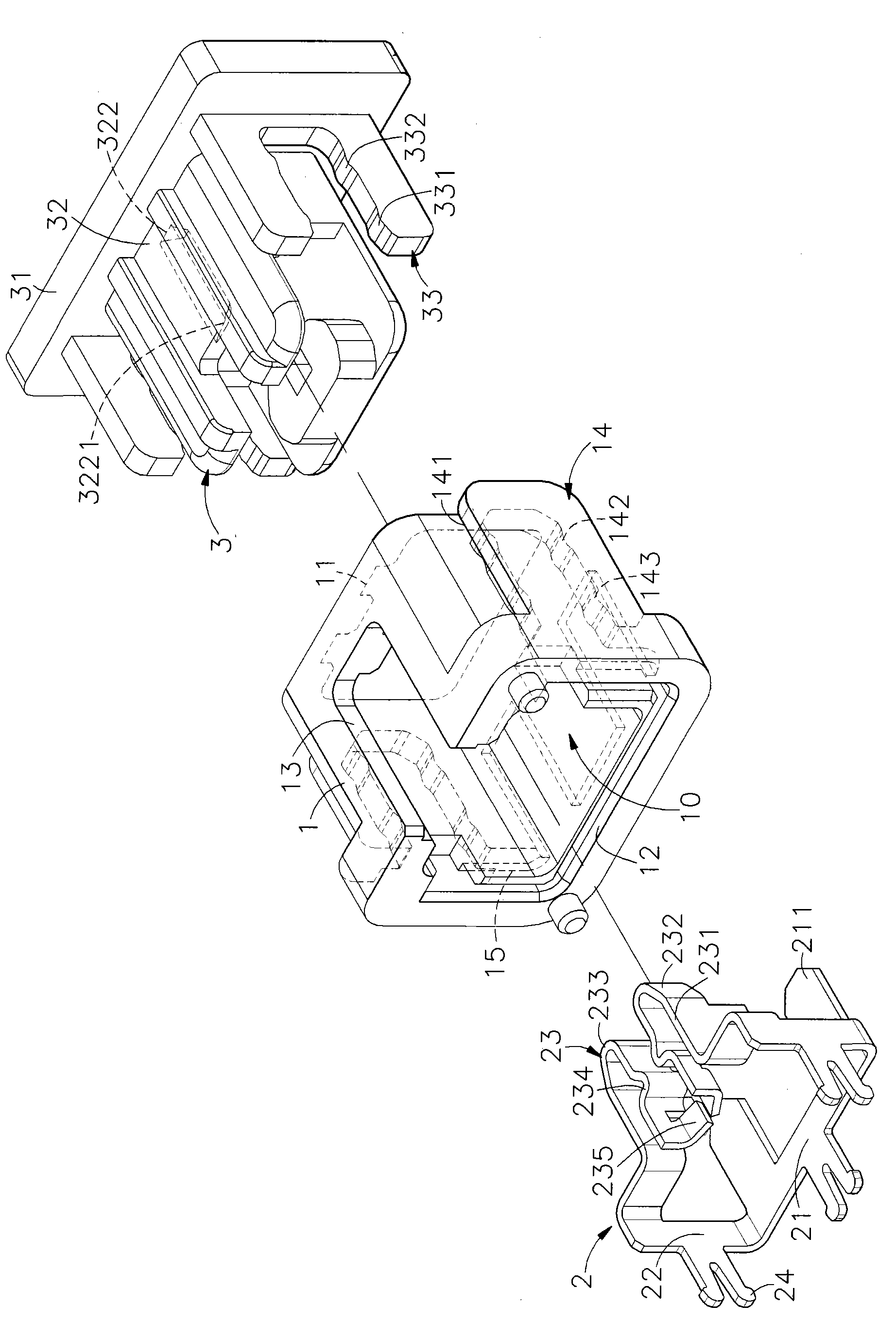

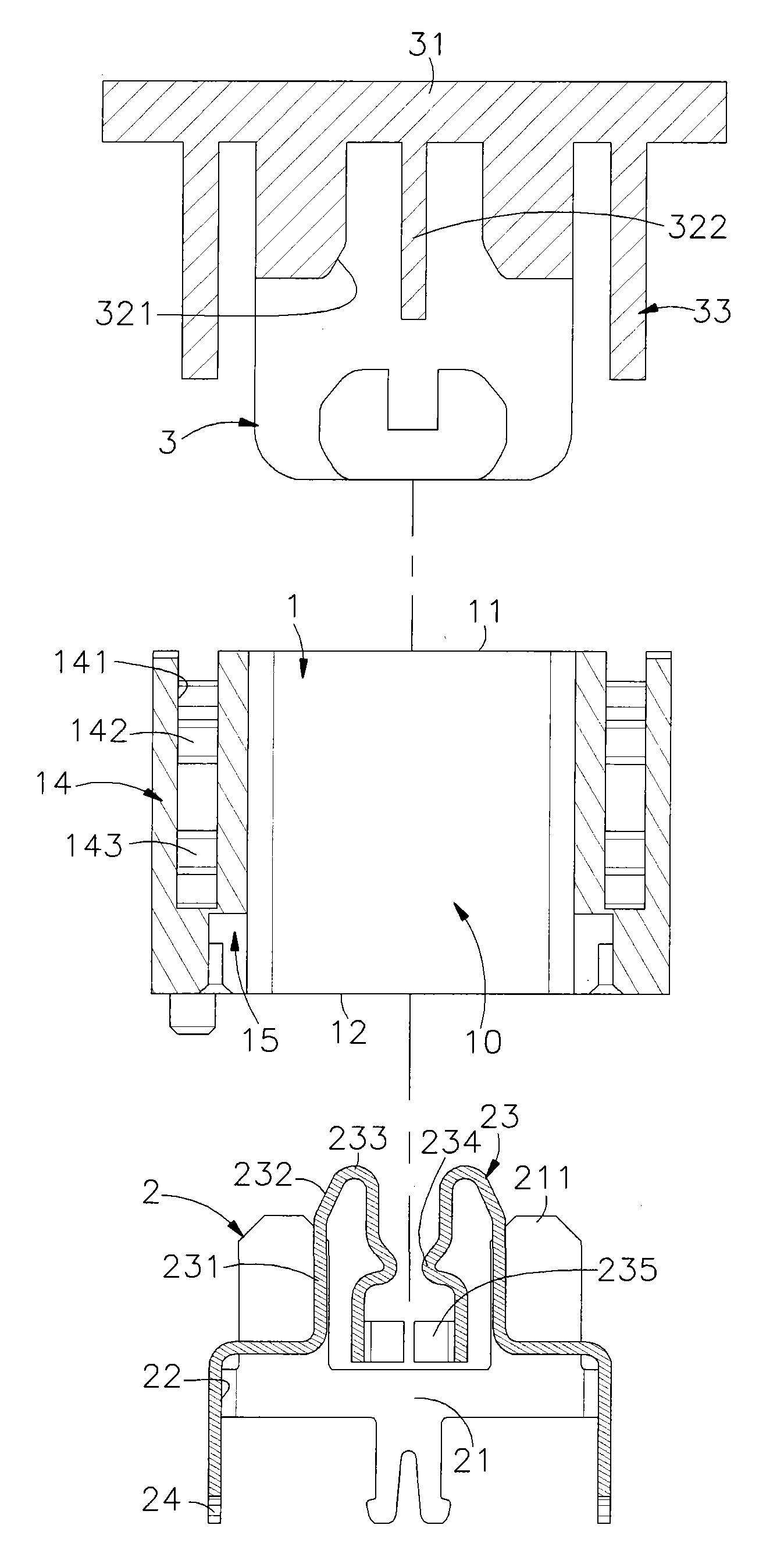

[0026] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0027] The lamp tube connection structure assembled by the lamp tube connector assembly method described in the embodiment of the present invention includes a lamp tube connector, a circuit board 4 and a fluorescent tube 5 .

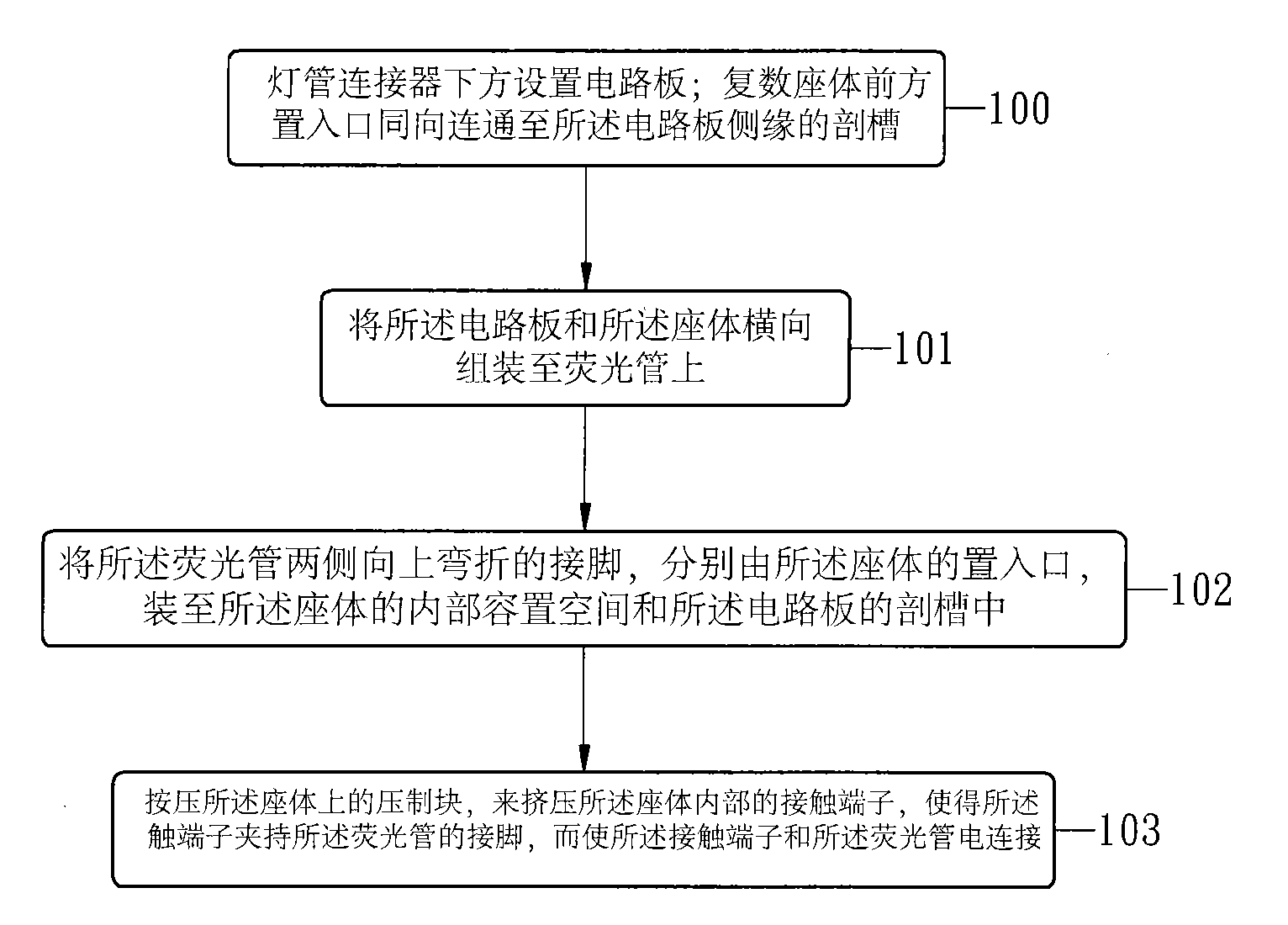

[0028] see figure 1 , is the flow chart of the assembly action of the present invention. It can be clearly seen from the figure that the assembly method of the light tube connector described in the embodiment of the present invention is carried out according to the following steps:

[0029] Step 100: Install a circuit board 4 under the lamp connector; connect the openings 13 at the front of the seat body 1 to the slot 41 on the side edge of the circuit board 4 in the same direction;

[0030] Step 101: Assembling the circuit board 4 and the seat 1 horizontally onto the fluorescent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com