Front loading washing machine

A drum washing machine and drum technology, which is applied in the field of washing machines, can solve the problems of drum mechanical failure, looseness, and easy embrittlement of materials, and achieve the effects of preventing mechanical failure, improving assembly accuracy, and improving fastening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

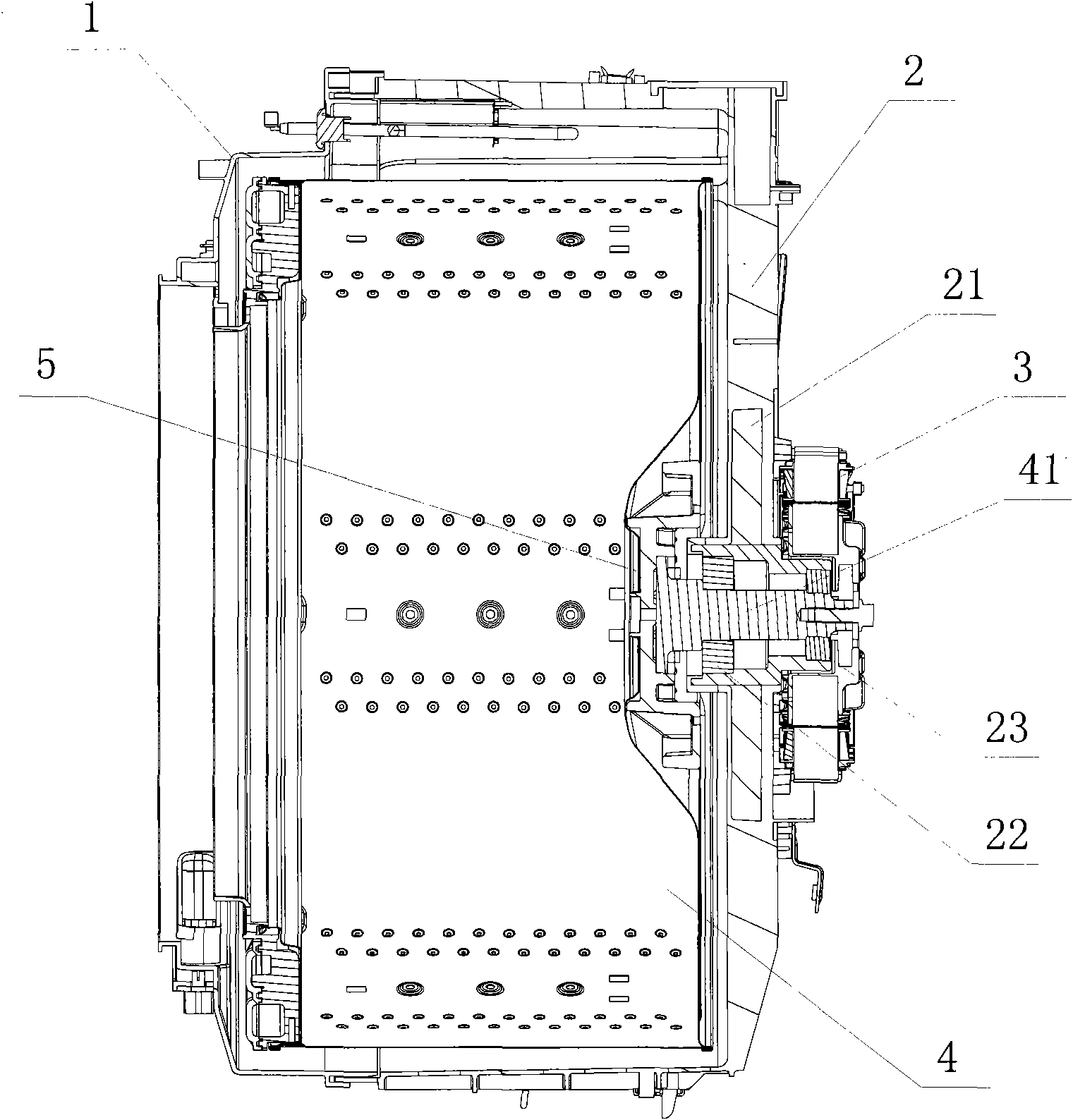

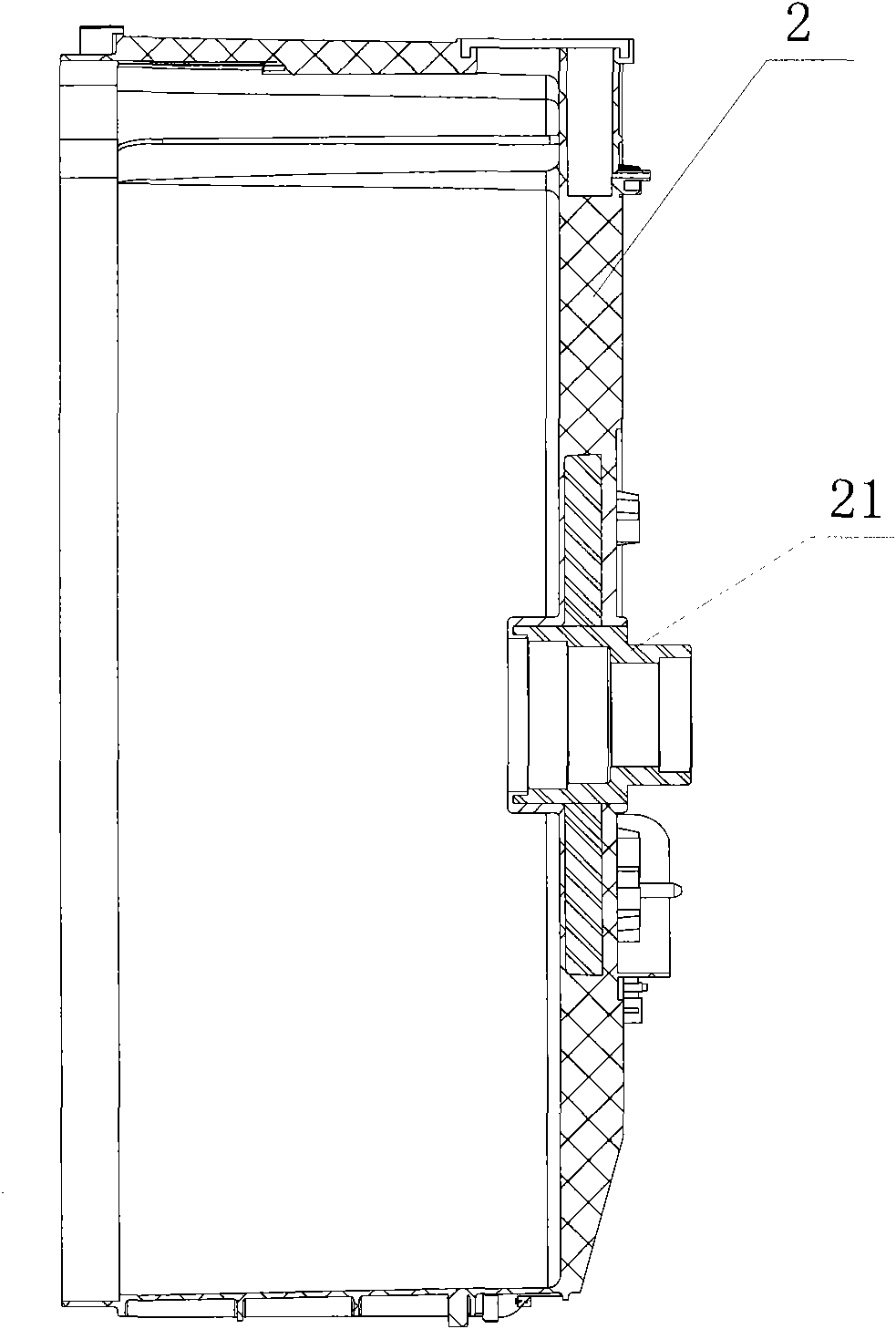

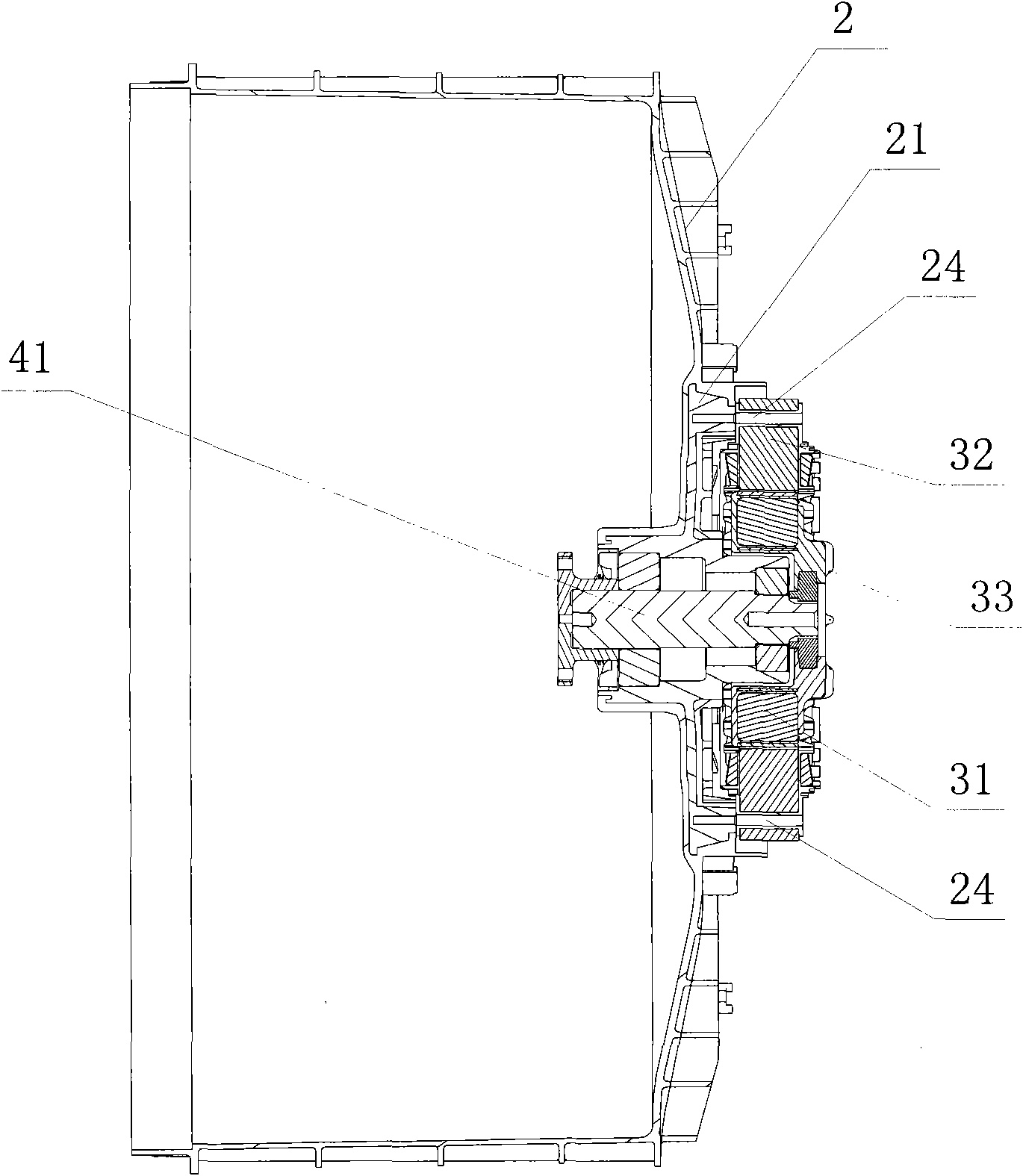

[0031] like Figure 1 to Figure 3 As shown, the drum washing machine described in this embodiment mainly has a casing 1, an outer tub 2 for storing washing water is arranged inside the casing 1, and a motor 3 providing a driving force is connected and fixed on the rear side of the outer tub.

[0032] Inside the outer tub 2 is provided a drum 4 which is rotatable for washing.

[0033] The drum shaft 41 that transmits the driving force of the motor 3 to the drum 4 is connected to the rear of the drum 4 and runs through the rear of the tub 2 , and the rear end of the drum shaft 41 is connected to the motor rotor 31 .

[0034] The outer barrel 2 is made of plastic, such as PVC.

[0035] Drum shaft 41 selects metal material for use, as adopting stainless steel material to make drum shaft 41 as a whole.

[0036] The cylindrical bearing seat 21 is embedded in the rear of the tub 2, and is prefabricated into an integrated structural part through injection molding process. The beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com