Closed float valve

A float valve and valve body technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of easy deformation, unusable, water seepage and other problems of sealing parts, and achieve the effect of improving sealing effect, simple structure and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

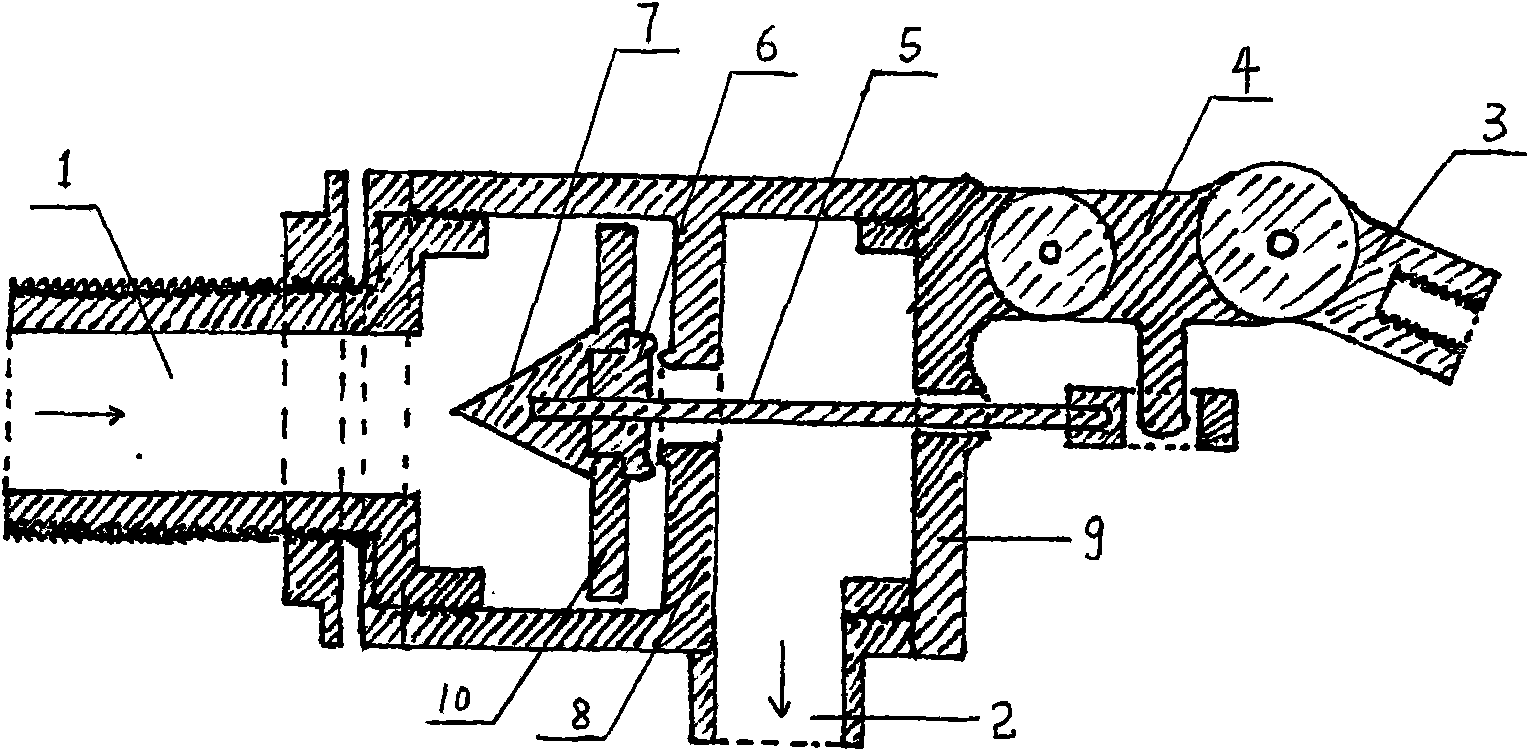

[0012] The closed floating ball valve of the present invention consists of a water inlet 1, a water outlet 2, a ball rod connected to a pendulum 3, a push-pull rod connected to a pendulum 4, a push-pull rod 5, a sealing gasket 6, a sealing support 7, a water blocking wall 8 and a valve body 9, one end of the valve body 9 is connected with a ball rod connected to the pendulum block 3, the other end is a water inlet 1, there is a water outlet 2 at the middle bottom of the valve body 9, and a sealed cavity is formed between the water blocking wall 8 and the water outlet 2 , The water inlet end of the water blocking wall has seals 6 and 7, the seals 6, 7 are fixedly connected with the push-pull rod 5, and the push-pull rod 5 is fixedly connected with the pendulum block 4 connected with the push-pull rod. The connection and the function between the push-pull rod connecting the pendulum 4 and the club connecting the pendulum 3 are present technology.

Embodiment 2

[0014] Other parts are the same as in Embodiment 1, and there are 2-6 positioning pieces 10 between the sealing gasket 6 and the sealing holder 7 .

Embodiment 3

[0016] Other parts are the same as in Embodiment 1, and the push-pull rod 5 is movably connected with the pendulum block 4 connected with the push-pull rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com