Concrete mixing ratio design method based on artificial intelligence

A mix design and artificial intelligence technology, applied in neural learning methods, calculations, calculation models, etc., can solve the problems of inability to effectively guarantee durability and crack resistance, lack of durability, crack resistance, and single performance. Achieve the effect of reducing the number of trials, saving manpower and time

Inactive Publication Date: 2009-12-23

福建省融旗建设工程有限公司 +1

View PDF0 Cites 27 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the incorporation of mineral admixtures and admixtures, it is difficult to prepare high-performance concrete with complex components and special performance requirements based on experience-based concrete mix design methods

The third is that the performance considered is relatively single, ma

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

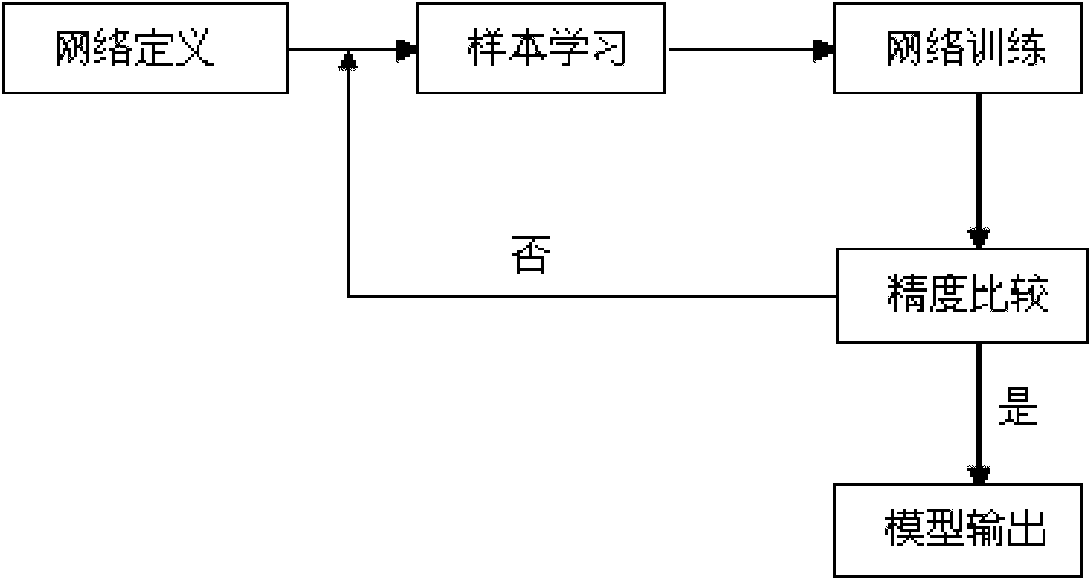

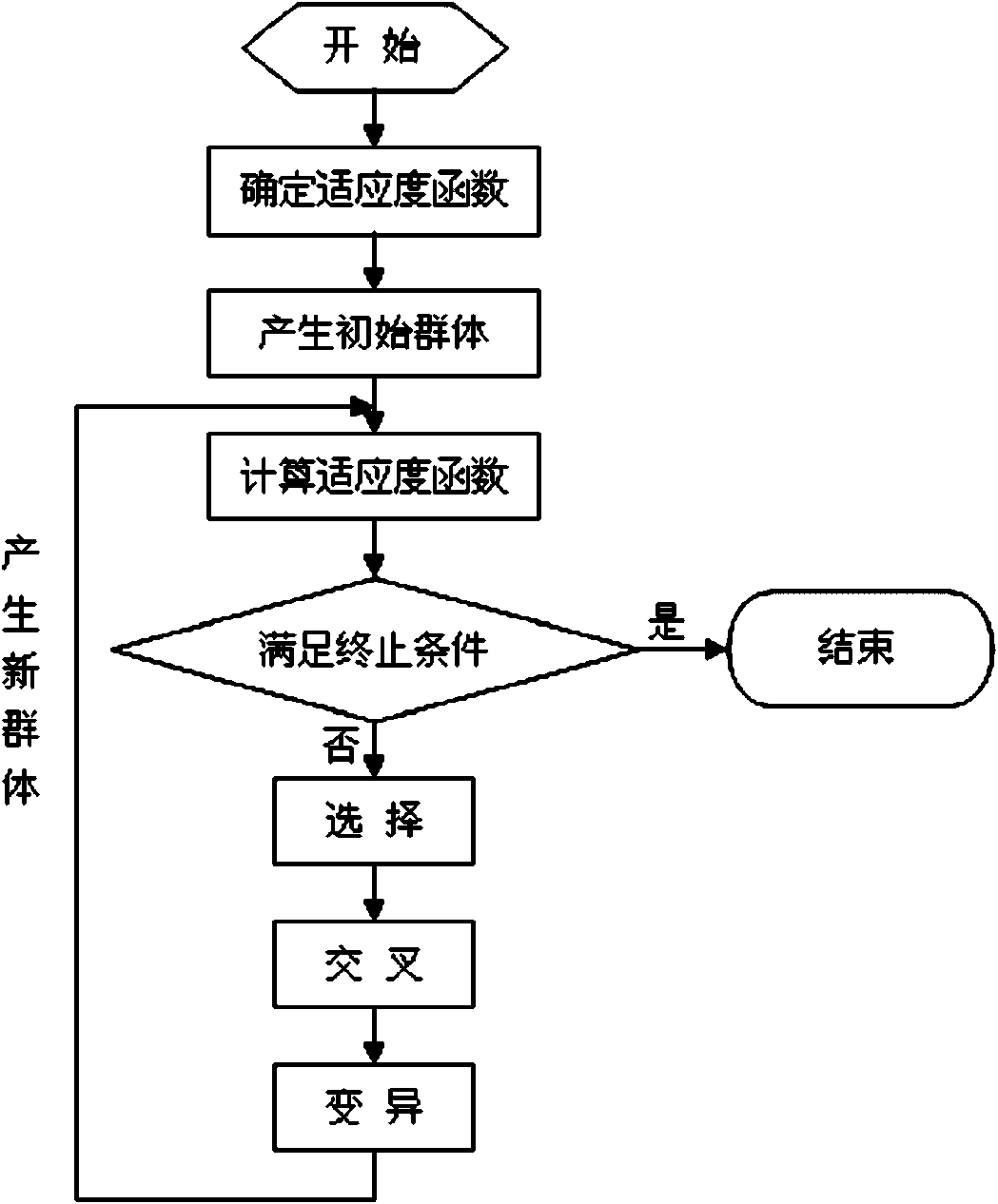

The invention relates to the technical field of a concrete mixing ratio design, in particular to a concrete mixing ratio design method based on artificial intelligence, which comprises the following steps of : (1) adopting an artificial neural network method to establish a relation between concrete performance index and concrete mixing ratio so as to obtain a concrete performance prediction artificial neural network model; (2) based on the concrete performance prediction artificial neural network model, adopting genetic algorithm, aiming at meeting all performance requirements and leading the cost to be lowest, designing and optimizing to the concrete mixing ratio; and (3) retraining the concrete performance prediction artificial neural network model if the concrete mixing ratio obtained by optimization is not in the learned range of the artificial neural network. The concrete mixing ratio design method based on artificial intelligence is beneficial to quickly and accurately designing a concrete mixing ratio which can meet a plurality of performance requirements and has lower cost.

Description

technical field [0001] The invention relates to the technical field of concrete mix ratio design, in particular to an artificial intelligence-based concrete mix ratio design method. Background technique [0002] Since the existence of concrete, there has been a problem of how to make the composition of concrete meet the needs of engineering. At present, most of the concrete used in civil engineering in my country still follows the traditional design mode of determining the concrete mix ratio by strength and slump. [0003] The traditional design method is an experience-based trial-and-match method with the main objective of meeting workability and strength requirements, based on the relationship between strength and water-cement ratio. However, with the development of the construction industry, various new types of concrete (such as high-strength concrete and high-performance concrete) have appeared one after another in order to meet the special technical requirements of en...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06N3/00G06N3/063G06N3/08G06N3/12B28B7/04

Inventor 季韬罗蜀榕林旭健黄萍梁咏宁

Owner 福建省融旗建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com