Automatic warehouse

A technology for automated warehouses and goods, applied in the field of automated warehouses, can solve problems such as increased buckling, larger bracket sizes, and damage to the structural stability of automated warehouses, achieving simple structures, structural stability, space utilization, and economic benefits The effect of advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in more detail by way of exemplary embodiments with reference to the accompanying drawings.

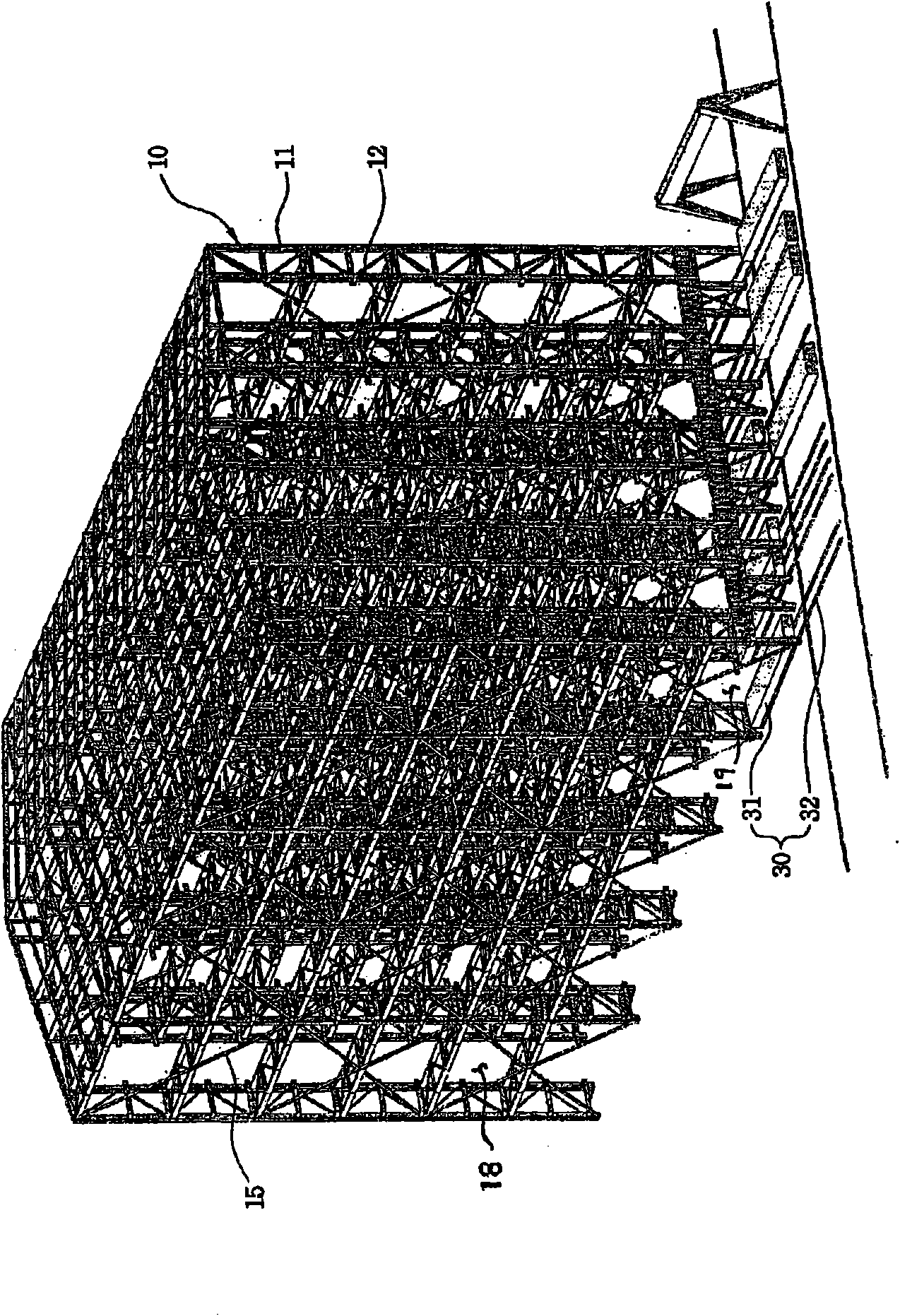

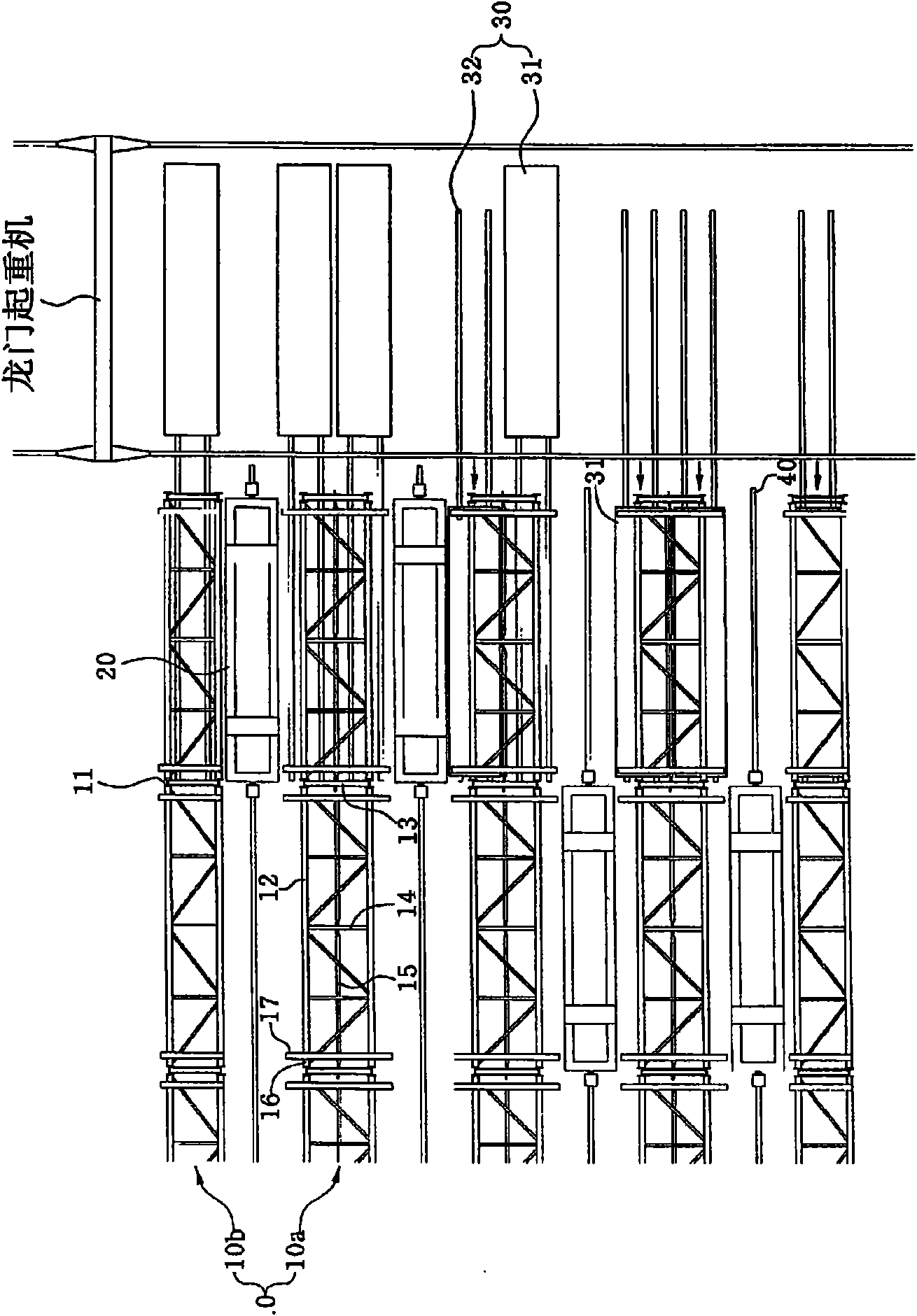

[0037] refer to Figures 1 to 4 , the automated warehouse according to the present invention comprises: several racks 10 arranged longitudinally in a grid shape so that goods "W" are placed on each cargo loading area 18; a stacking crane 20 is arranged between two adjacent racks 10 , for moving up or down, or retrieving the goods "W" from the goods loading area 18; and a transfer device 30, for moving the goods "W" from inside and outside of the warehouse.

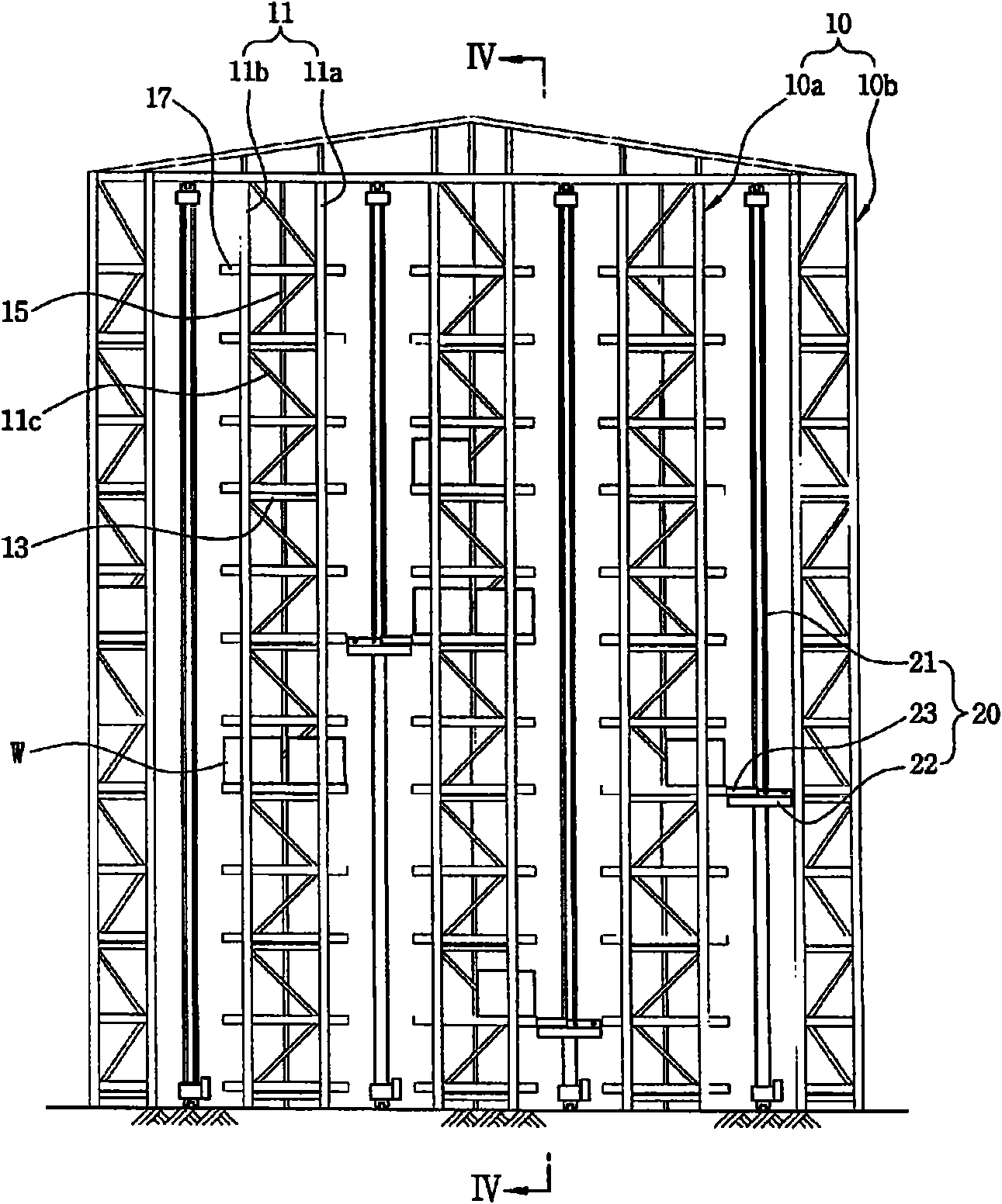

[0038] Such as Figures 5 to 10 As shown in , the rack 10 includes several pairs of columns 11, several pairs of horizontal beams 12, first support beams 13, second support beams 14, vertical supports 15, arm beams 16 and loading arms 17 connected to each other in a matrix pattern.

[0039] Each pair of uprights 11 includes two uprights 11a, 11b vertically arranged widthwise at pred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com