Method and device for encapsulating electronic components using underpressure

A technology for electronic components and vacuum packaging, which is applied in electrical components, electric solid-state devices, semiconductor devices, etc., and can solve problems such as the quality of packaging not reaching the expected effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

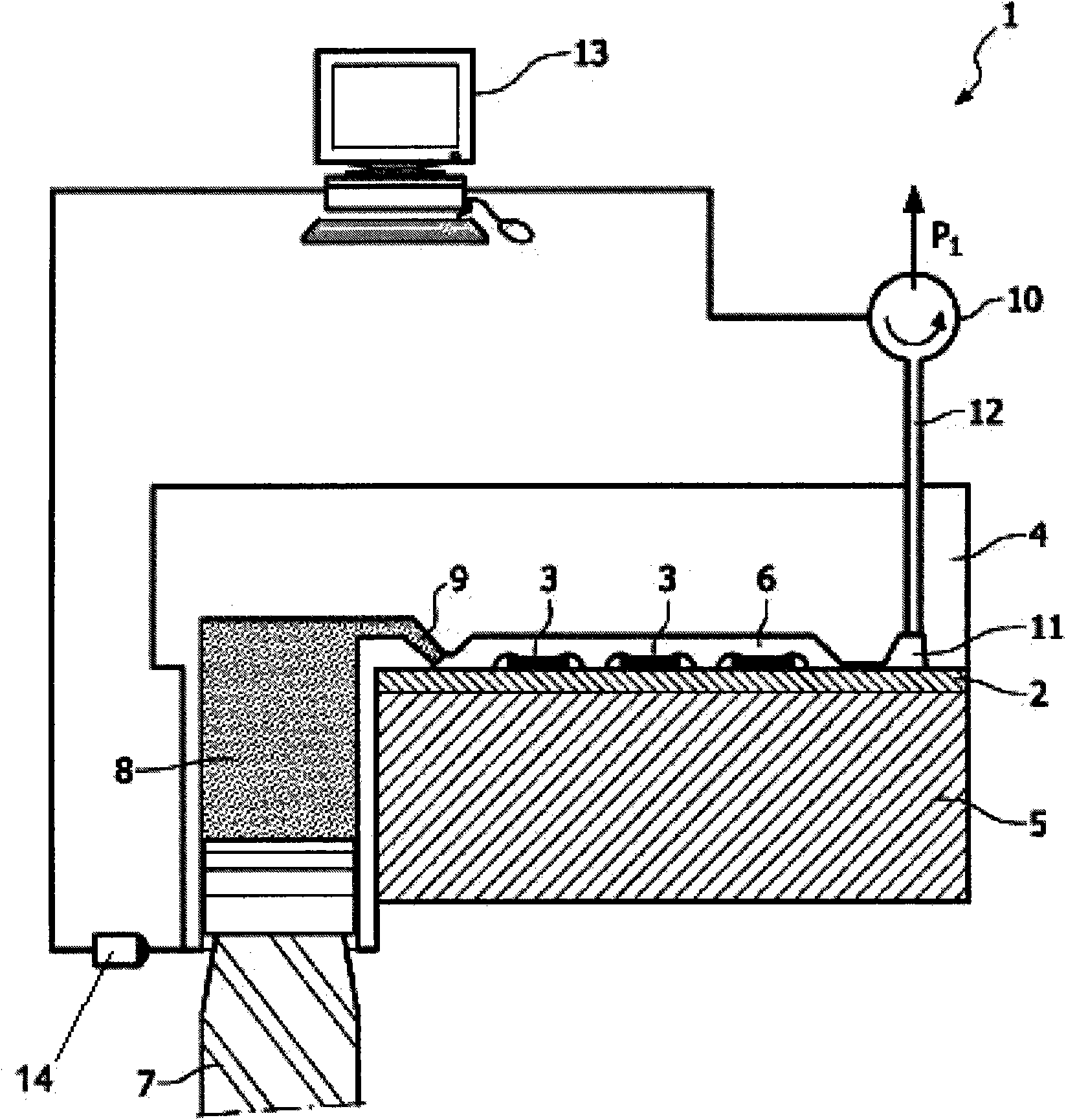

[0022]FIG. 1 shows a device 1 for packaging electronic components 3 arranged on a carrier 2 . The carrier is clamped between the two mold parts 4 , 5 , so that the electronic component 3 can be accommodated here in the mold cavity 6 , which is to the left of the upper mold part 4 . The encapsulating material 8 becomes liquid after being heated, and enters the mold cavity 6 through the gate 9 under the push of the piston 7 . In order to make the packaging material 8 fill the mold cavity better, gas (usually air, and possibly the gas volatilized in the packaging material) can be pumped out to the external environment through the pumping chamber 11 and the pumping channel 12 under the action of the pump 10 in (see arrow P 1 ).

[0023] The device 1 further includes an intelligent controller 13, which is shown as a computer in this figure. Preferably, the computer is equipped with multiple menu programs for use. The vacuuming process in the mold cavity 6 is controlled. The sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com