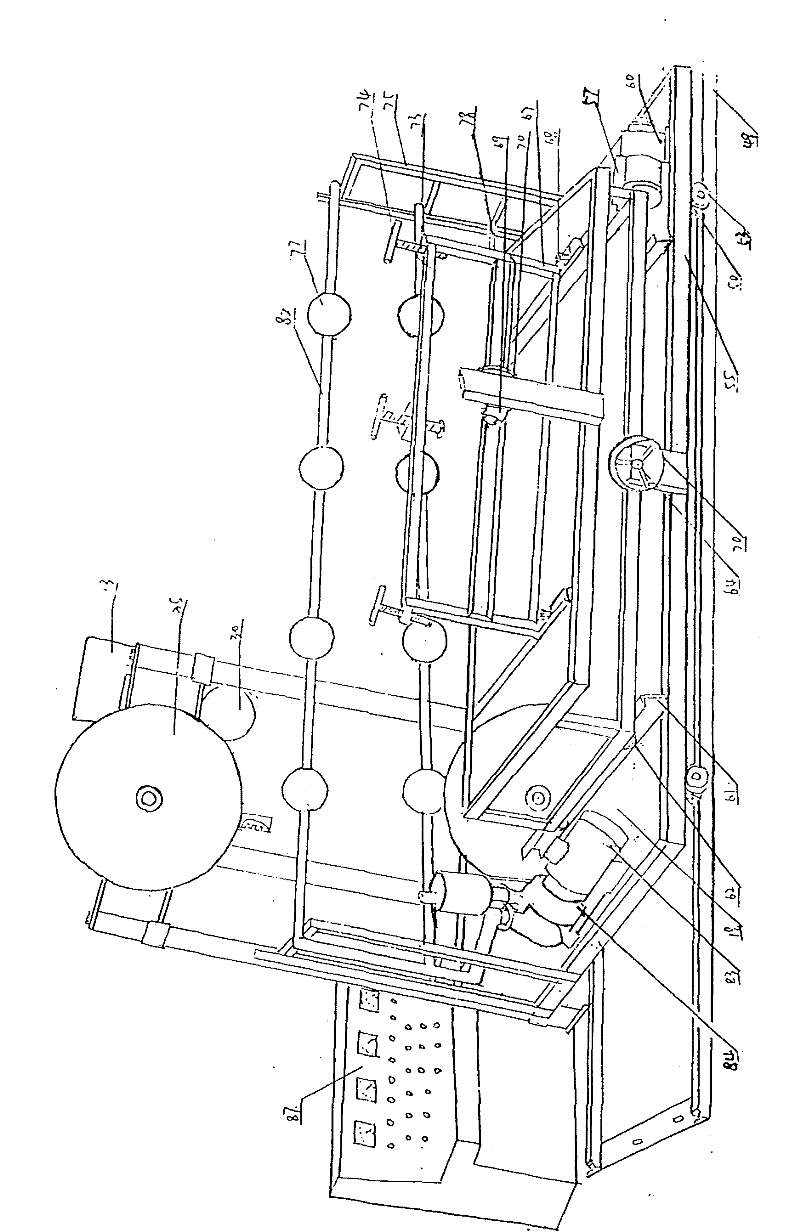

Double-blade counter-cutting plate opening machine

A double-blade, trigger technology, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of low utilization rate of finished materials and high product cost, and achieve the effect of cost saving, low cost and narrow knife tip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

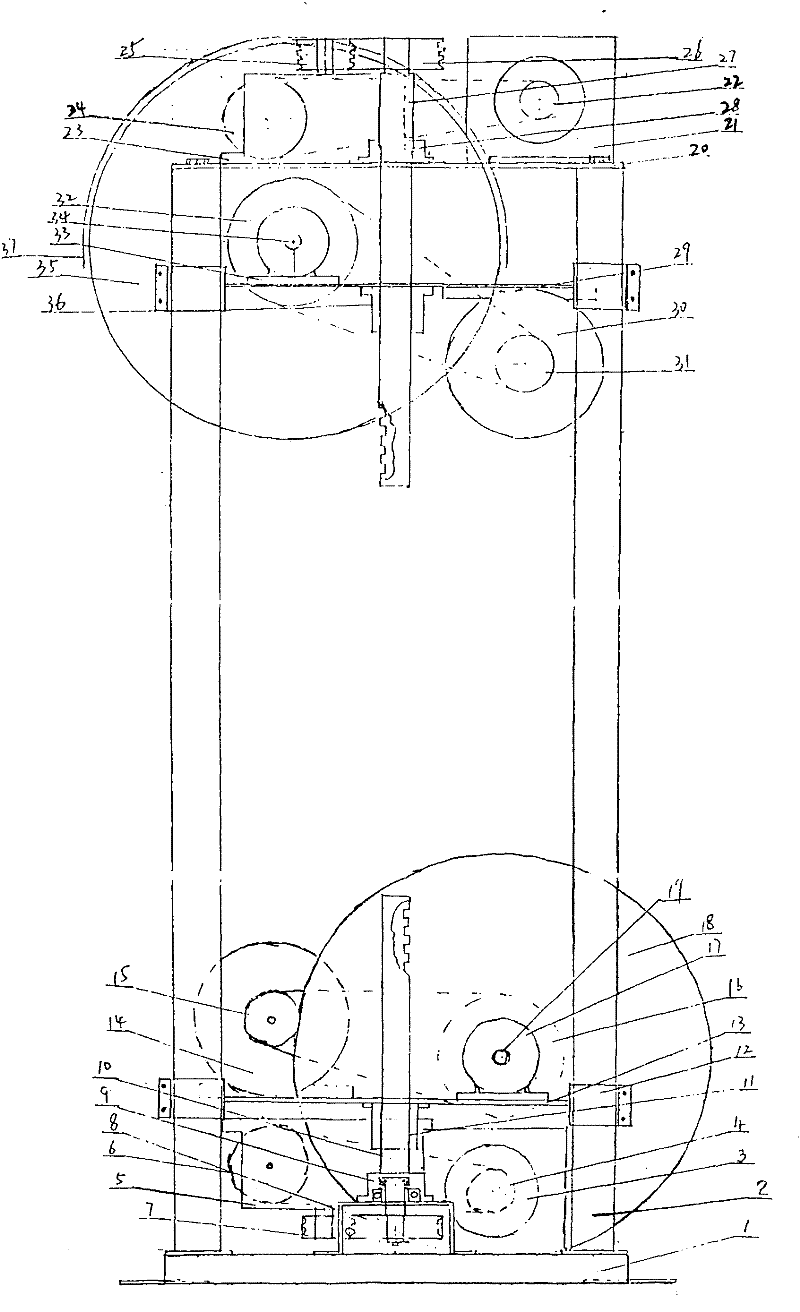

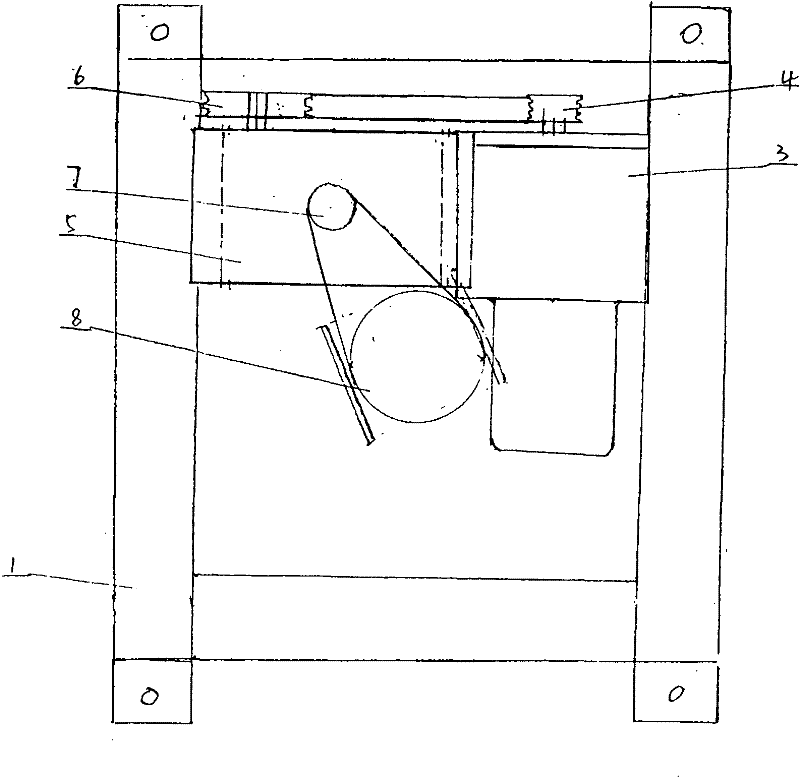

[0023] The double-blade pair cutting machine is mainly divided into three parts, the lifting and rotating part of the saw blade, the moving part of the stone clamping and the electrical control part.

[0024] The lifting and rotating part of the saw blade is realized in this way: the bottom plate 1 is installed on the concrete foundation and is perpendicular to the ground, four columns 2 are fixedly connected to the base 1, and the outer diameter of the column 2 is covered with 4 sleeves 12 and the column 2 It is a sliding fit, and the saw blade seat carrier plate 13 is fixedly connected to the outside of the four sleeves 12 . Base plate The base plate 1 is equipped with a speed-regulating motor 3, the belt pulley 4 of the speed-regulating motor 3 is connected in rotation with the input belt pulley 6 of the reduction box through the V-belt, and the output belt pulley 7 of the reduction gear box is rotated through the V-belt and the screw belt pulley 8. Connect, screw bearing s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap