Hydrocarbon retaining system configuration for an internal combustion engine

A hydrocarbon and retention system technology, applied in the direction of internal combustion piston engines, combustion engines, engine components, etc., can solve problems such as prolonged extraction operation, increased cold start emissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

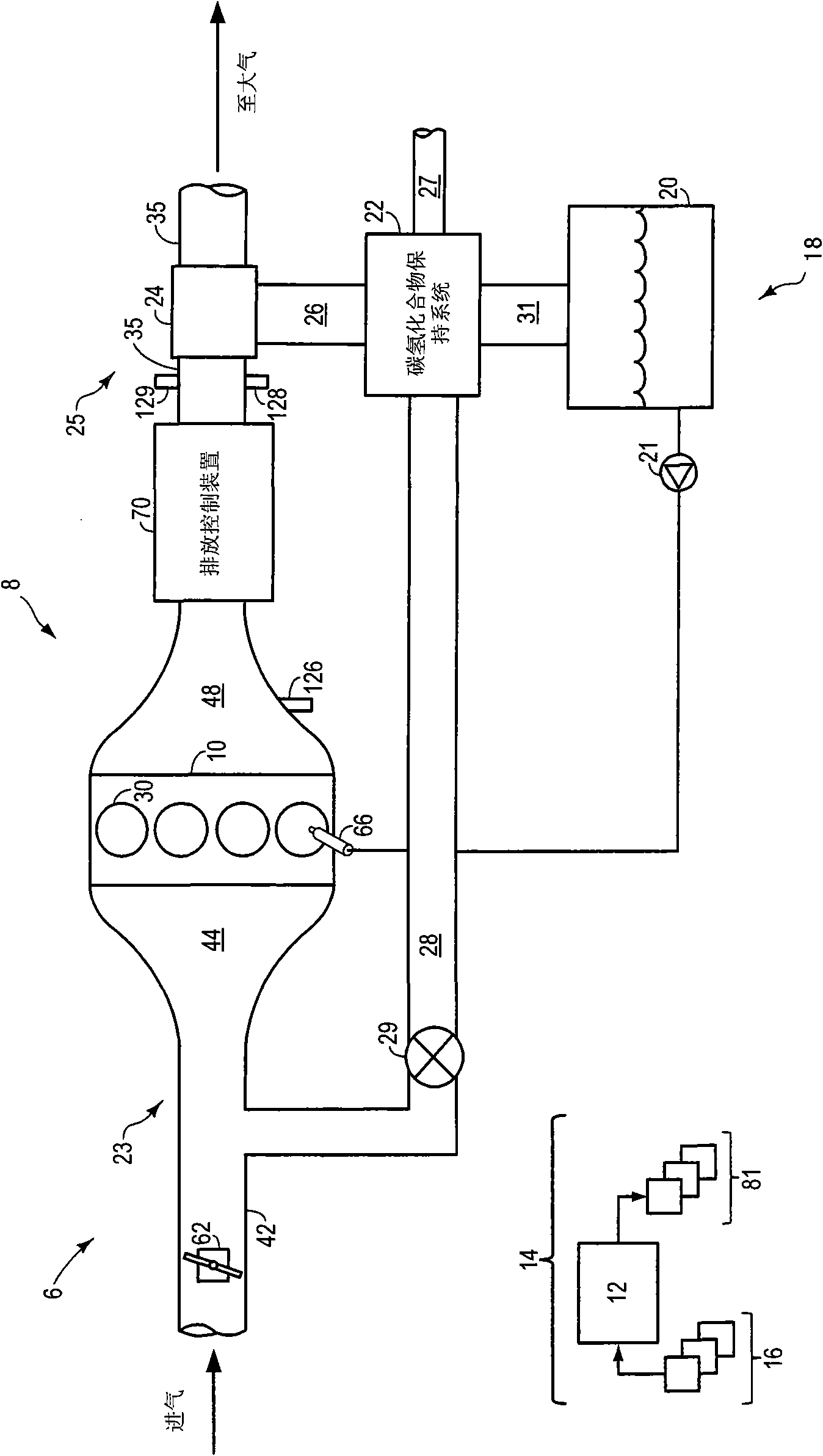

[0012] figure 1 A schematic diagram of a vehicle system 6 is shown. Vehicle system 6 includes engine system 8 connected to hydrocarbon (HC) retention system 22 and fuel system 18 .

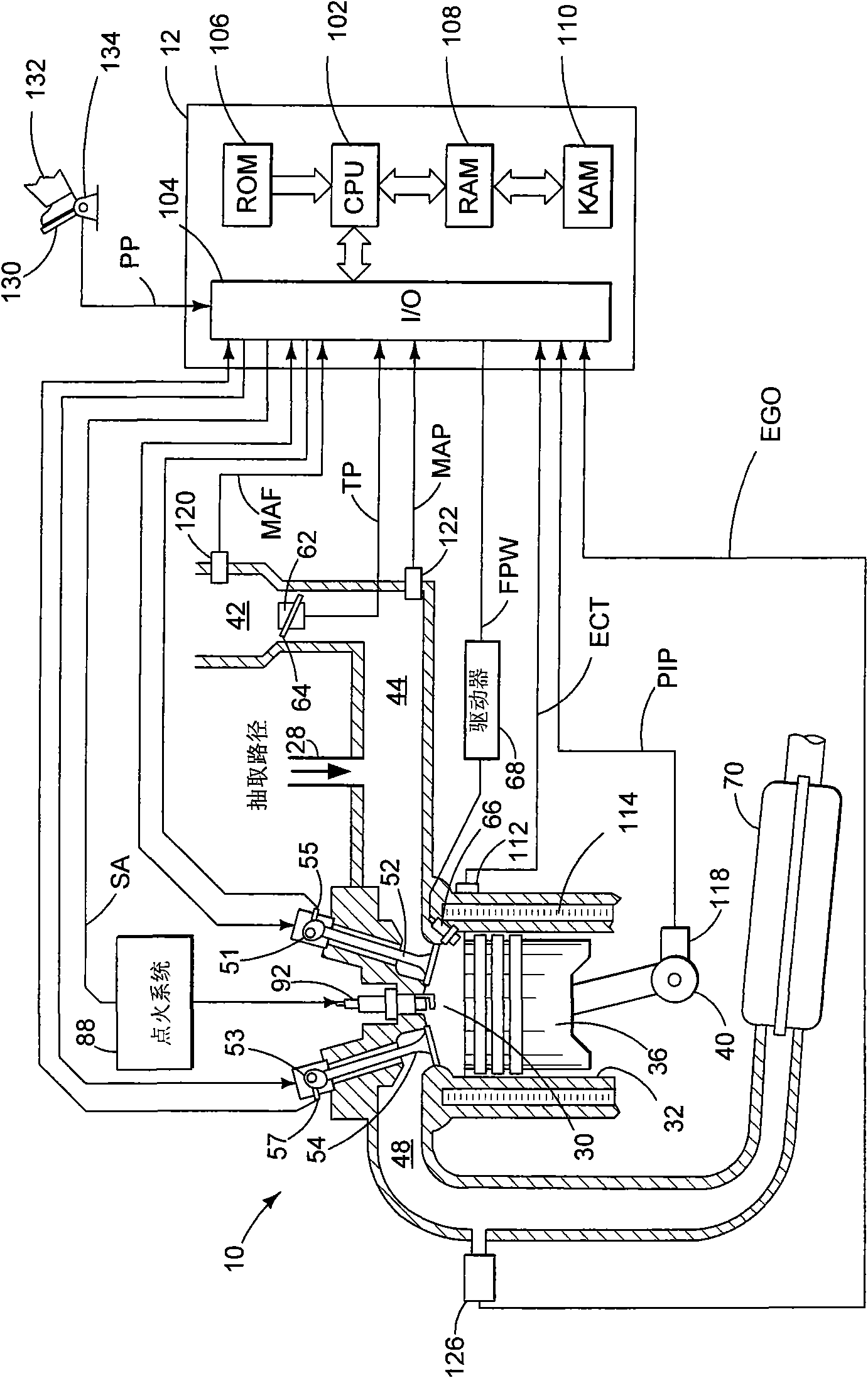

[0013] Engine system 8 may include engine 10 having a plurality of cylinders 30 . Engine 10 includes an intake system 23 and an exhaust system 25 . Intake system 23 includes throttle 62 fluidly coupled to engine intake manifold 44 via intake passage 42 . Exhaust system 25 includes an exhaust manifold 48 that leads to exhaust passage 35 that delivers exhaust to atmosphere. Exhaust system 25 may include one or more emission control devices 70 that may be mounted in close-coupled locations within the exhaust system. The one or more emission control devices may include a three way catalyst, a lean NOx trap, a diesel particulate filter, an oxidation catalyst, and the like. should be clearly as figure 2 As shown in the example engine of , other components such as various valves and sensors may be...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap