Method and instrument capable of accurately measuring thickness of ultrathin workpieces

A technology for precise measurement of workpieces, applied in instruments, measuring devices, using ultrasonic/sonic/infrasonic waves, etc., to solve the problems of inability to obtain the thickness of the object to be measured, the thickness of the workpiece cannot be measured, and the time interval cannot be measured.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

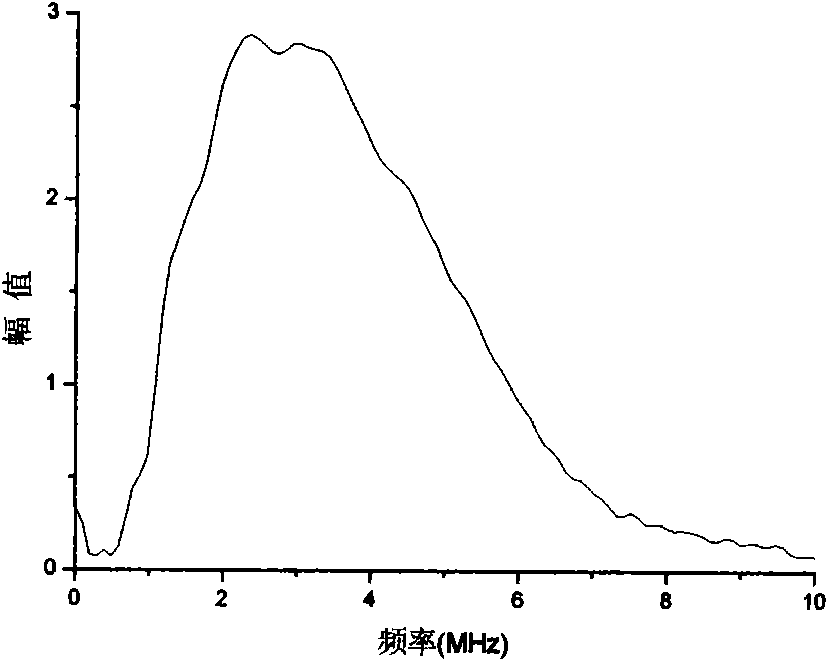

[0031] The invention provides a method capable of accurately measuring the thickness of an ultra-thin workpiece, which is characterized in that: the method for accurately measuring the thickness of an ultra-thin workpiece adopts a signal processing method to extract ultrasonic information representing the thickness of the workpiece, which is suitable for measuring ultra-thin large curvature The thickness of the workpiece is also suitable for the ultrasonic thickness measurement technology for measuring the thickness of ordinary workpieces. Its core is to perform fast Fourier transform (FFT) on the received echo signal to obtain the measurement results; the ultrasonic pulse has a certain frequency range, see image 3 , when the measured object is thin, the adjacent echoes overlap together, which will inevitably produce interference phenomenon. The ultrasonic vibrations of certain frequencies strengthen each other, while the ultrasonic vibrations of other frequencies weaken or comp...

Embodiment 2

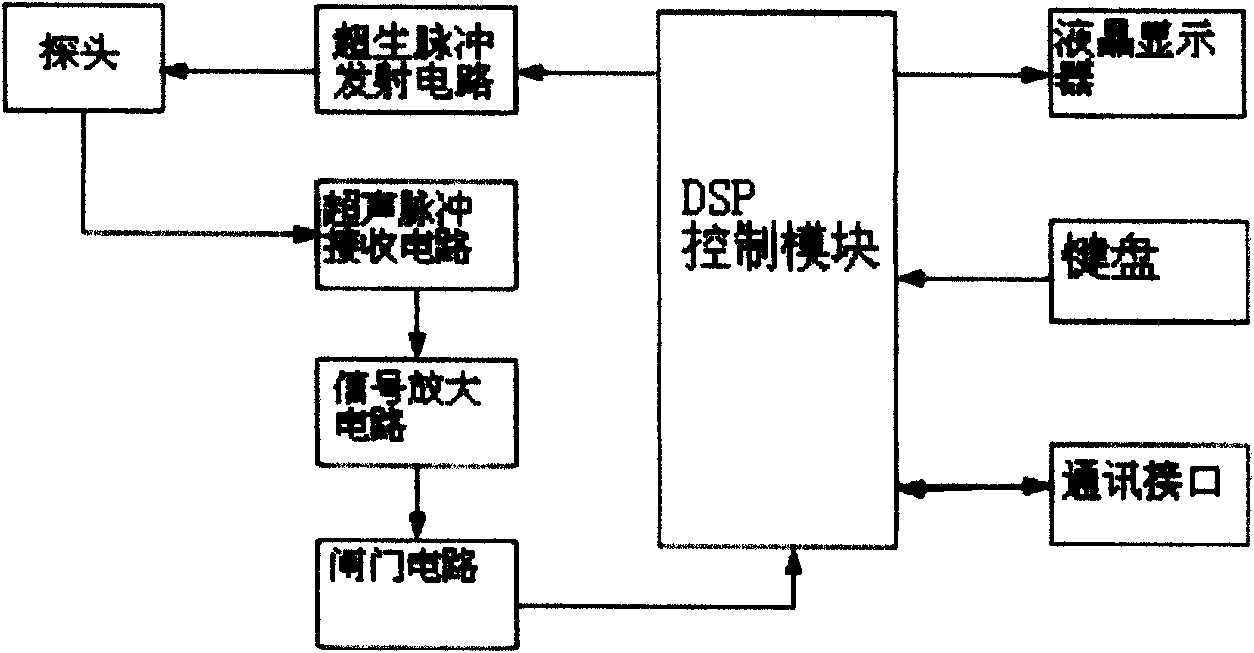

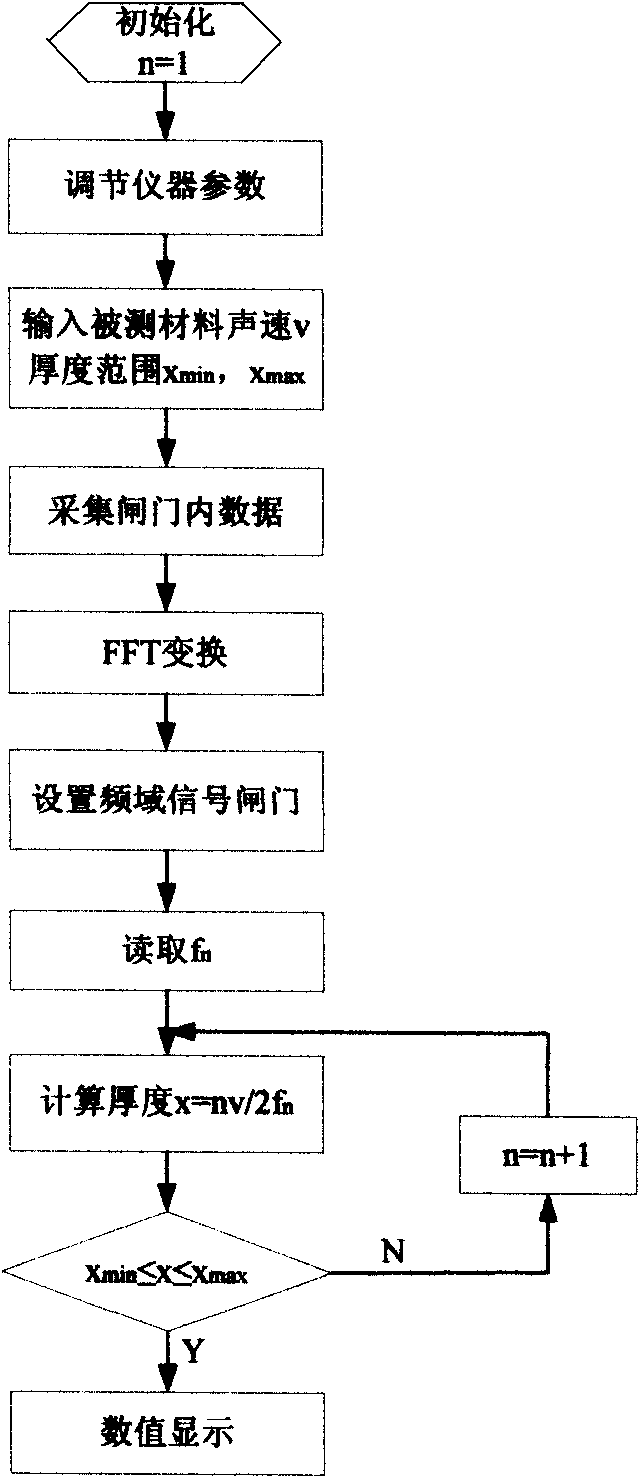

[0052] The invention provides a method capable of accurately measuring the thickness of an ultra-thin workpiece, which is characterized in that: the method for accurately measuring the thickness of an ultra-thin workpiece adopts a signal processing method to extract ultrasonic information representing the thickness of the workpiece, which is suitable for measuring ultra-thin large curvature The thickness of the workpiece is also suitable for the ultrasonic thickness measurement technology for measuring the thickness of ordinary workpieces. Its core is to perform fast Fourier transform (FFT) on the received echo signal to obtain the measurement results; the ultrasonic pulse has a certain frequency range, see figure 1 , when the measured object is thin, the adjacent echoes overlap together, which will inevitably produce interference phenomenon. The ultrasonic vibrations of certain frequencies strengthen each other, while the ultrasonic vibrations of other frequencies weaken or co...

Embodiment 3

[0073] The invention provides a method capable of accurately measuring the thickness of an ultra-thin workpiece, which is characterized in that: the method for accurately measuring the thickness of an ultra-thin workpiece adopts a signal processing method to extract ultrasonic information representing the thickness of the workpiece, which is suitable for measuring ultra-thin large curvature The thickness of the workpiece is also suitable for the ultrasonic thickness measurement technology for measuring the thickness of ordinary workpieces. Its core is to perform fast Fourier transform (FFT) on the received echo signal to obtain the measurement results; the ultrasonic pulse has a certain frequency range, see figure 1 , when the measured object is thin, the adjacent echoes overlap together, which will inevitably produce interference phenomenon. The ultrasonic vibrations of certain frequencies strengthen each other, while the ultrasonic vibrations of other frequencies weaken each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com