Maintenance control method and system used for semiconductor processing equipment

A technology for processing equipment and maintenance control, applied in the field of microelectronics, can solve the problems of waste of human, financial and material resources, small coupling of functional modules, and reduced production efficiency of semiconductor factories, so as to achieve high production efficiency and avoid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

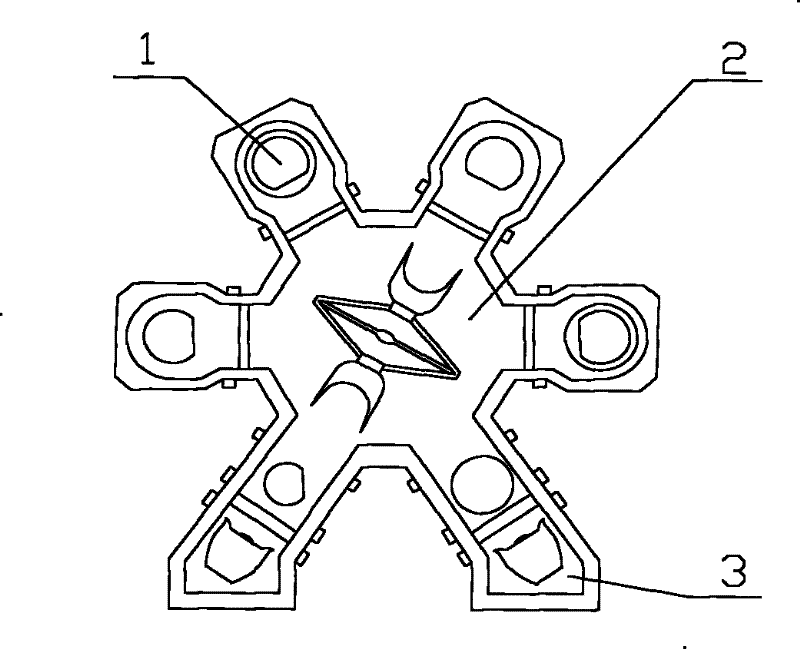

[0040] In order to enable those skilled in the art to better understand the technical solution of the present invention, the following in conjunction with the accompanying drawings and figure 1 The semiconductor processing equipment shown is taken as an example, and the maintenance control method and system for semiconductor processing equipment provided by the present invention and the semiconductor processing equipment provided by the present invention are described in detail. The semiconductor processing equipment includes functional modules such as a wafer aligner, a vacuum manipulator, an atmospheric manipulator, a vacuum lock chamber, a transfer chamber, and multiple reaction chambers. Wherein, two vacuum lock chambers can be called a group of parallel modules, and multiple reaction chambers can also be called a group of parallel modules.

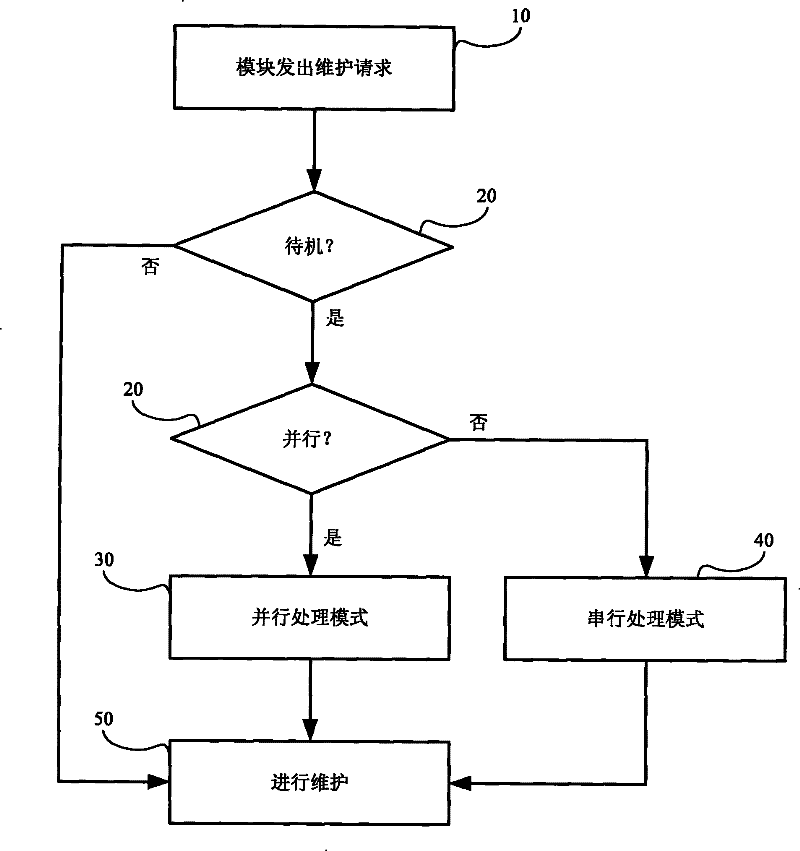

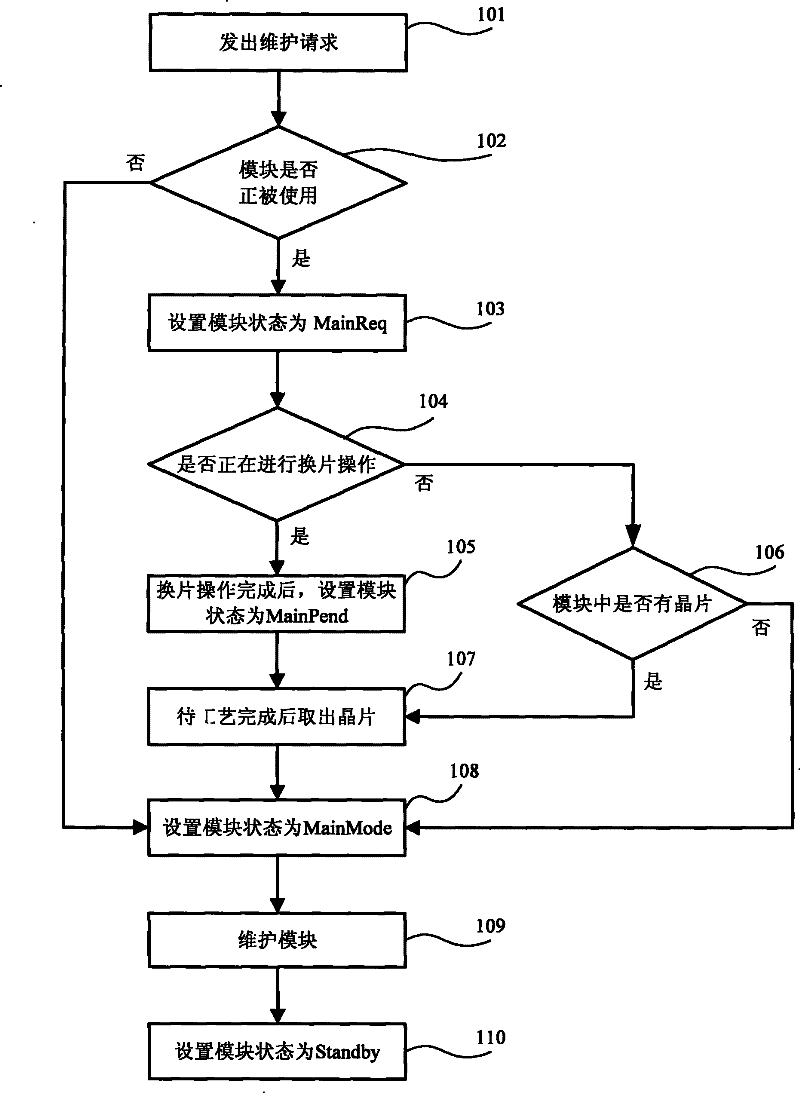

[0041] see figure 2 , the maintenance control method provided by the present invention may include the following steps:

[0042] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap