Galette

A godet and filament technology, applied in the directions of shafts, induction heating, induction heating devices, etc., can solve the problems of large equipment structure and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

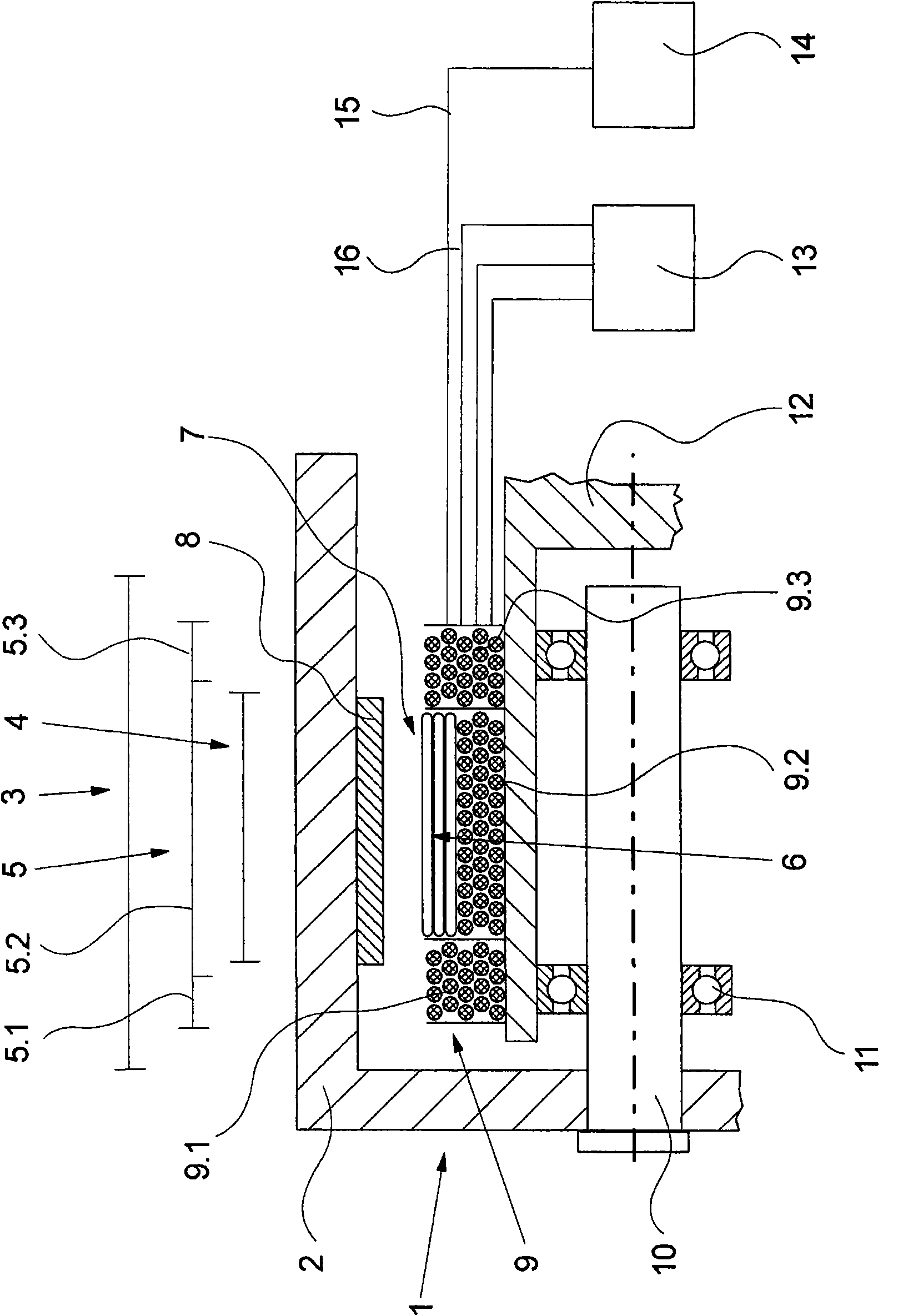

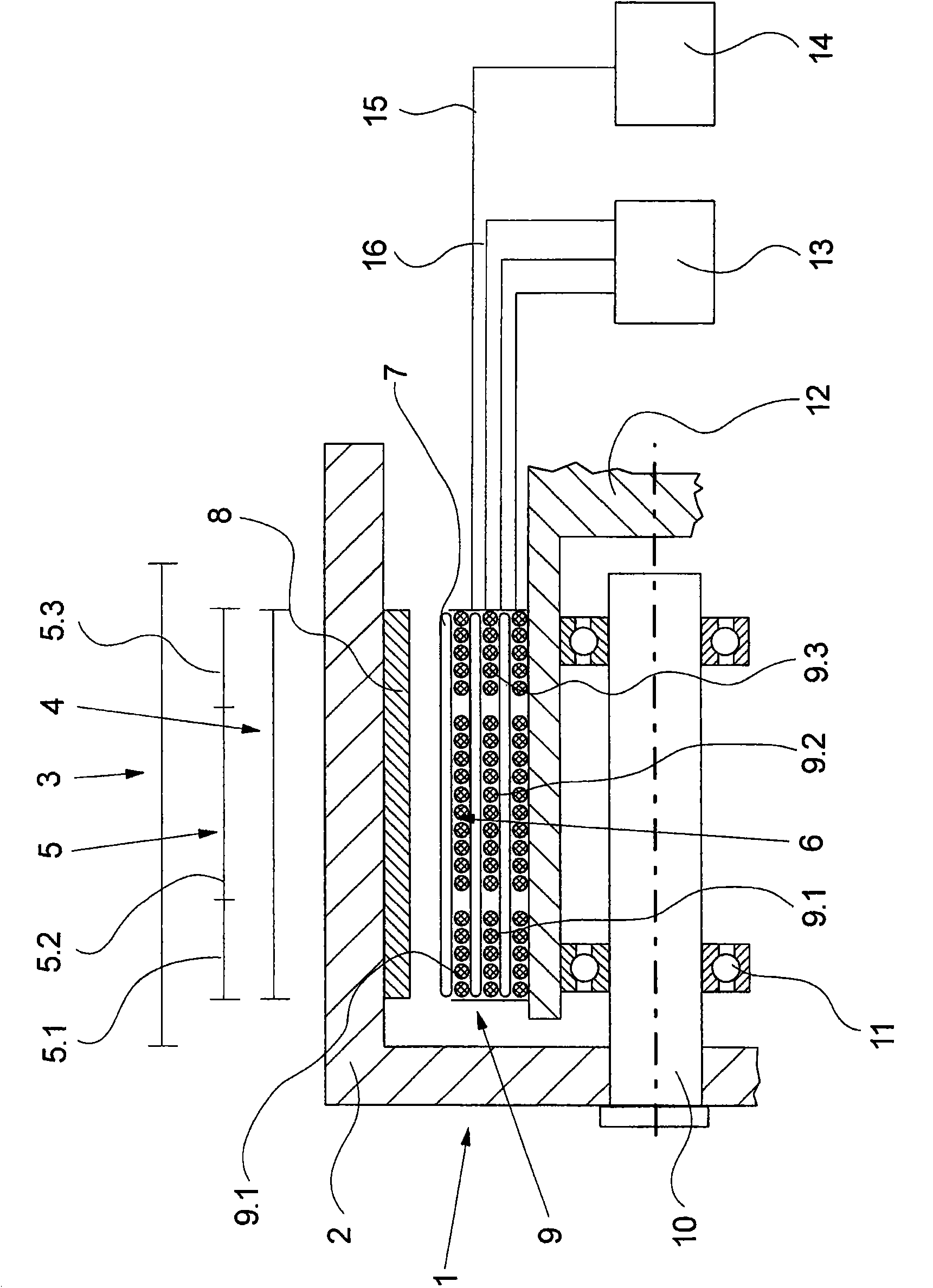

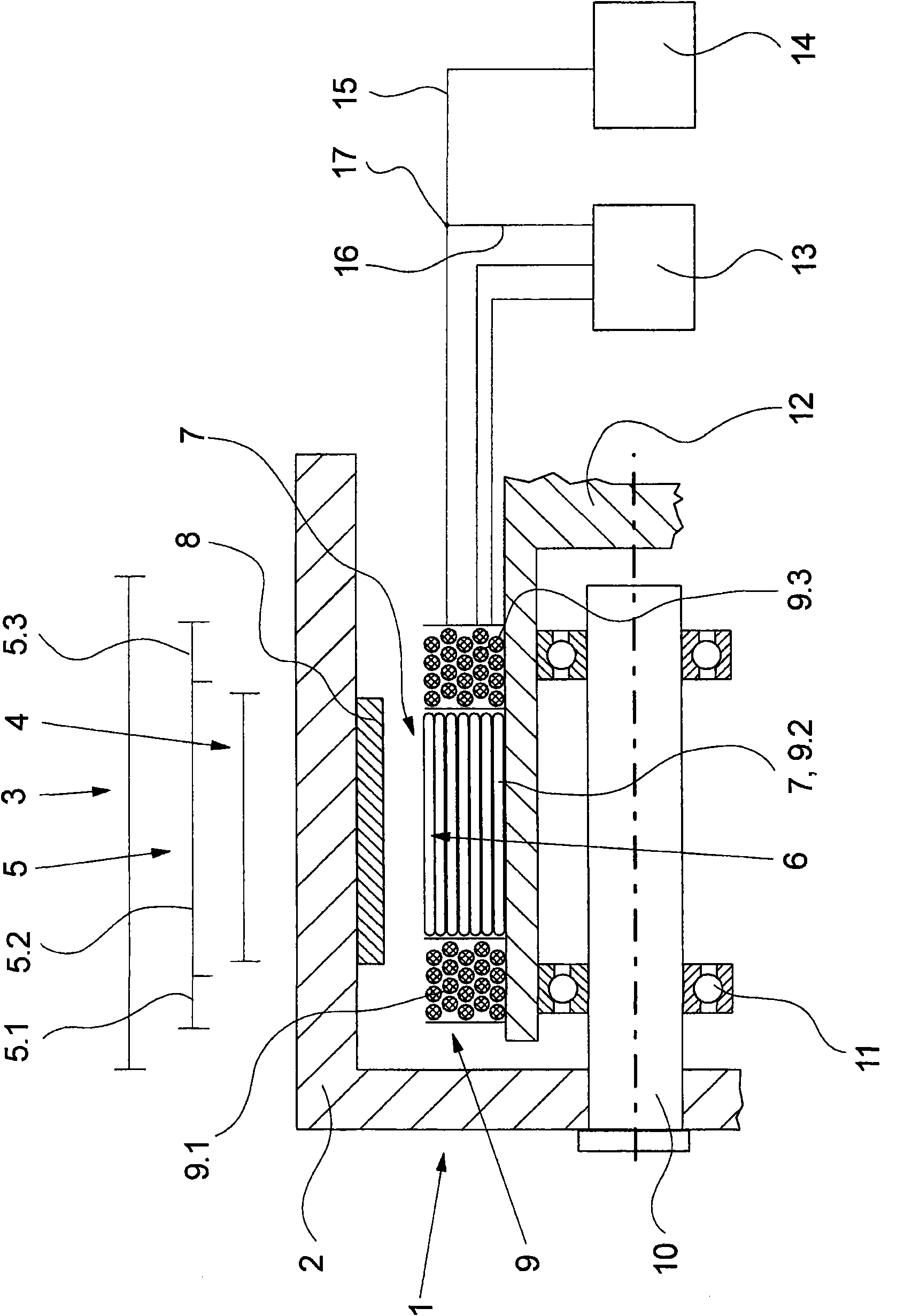

[0027] figure 1 A godet 1 is shown in section. The godet 1 essentially comprises a heatable godet housing 2 , which is connected to a shaft 10 mounted rotatably in a bearing 11 . On the outer circumference of the godet housing 2, the filaments can be guided in the guide region 3 in the form of half turns or in combination with a second godet or bypass roller in the form of multiple turns. On the one hand, a pulling force can be exerted on the filament due to friction, and on the other hand, the heat of the godet housing can be transferred to the filament by contact with the godet housing.

[0028] The filaments can be guided in an axially extending guide region 3 . The godet is heated in an axially extending heating zone 5 . Obviously, the practically usable guiding area is limited to the heating area 5 .

[0029] The bracket 12 in which the bearing 11 is fixed carries the heating coil 9 and the stator 6 at the same time. The heating coil 9 is fed with a high-frequency al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com