Multi-fuel internal combustion engine

A technology for internal combustion engines and fuels, applied to internal combustion piston engines, adding non-fuel substances to fuel, combustion engines, etc., can solve the problems of deterioration of emission performance and drivability, limited reduction of injection volume, and inability to suppress emission performance, etc., to achieve suppression Deterioration of exhaust emission performance and drivability, effect of good running

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

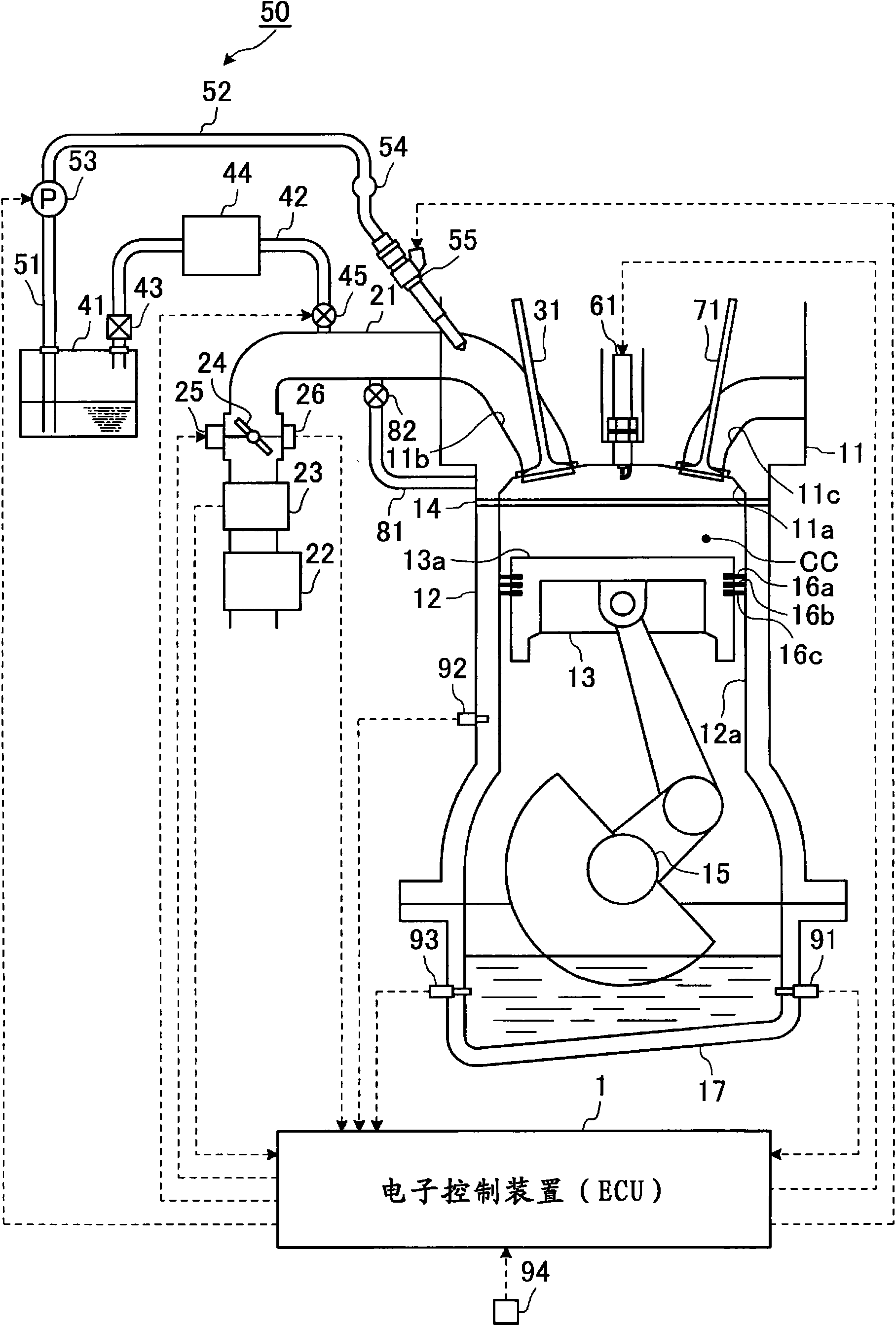

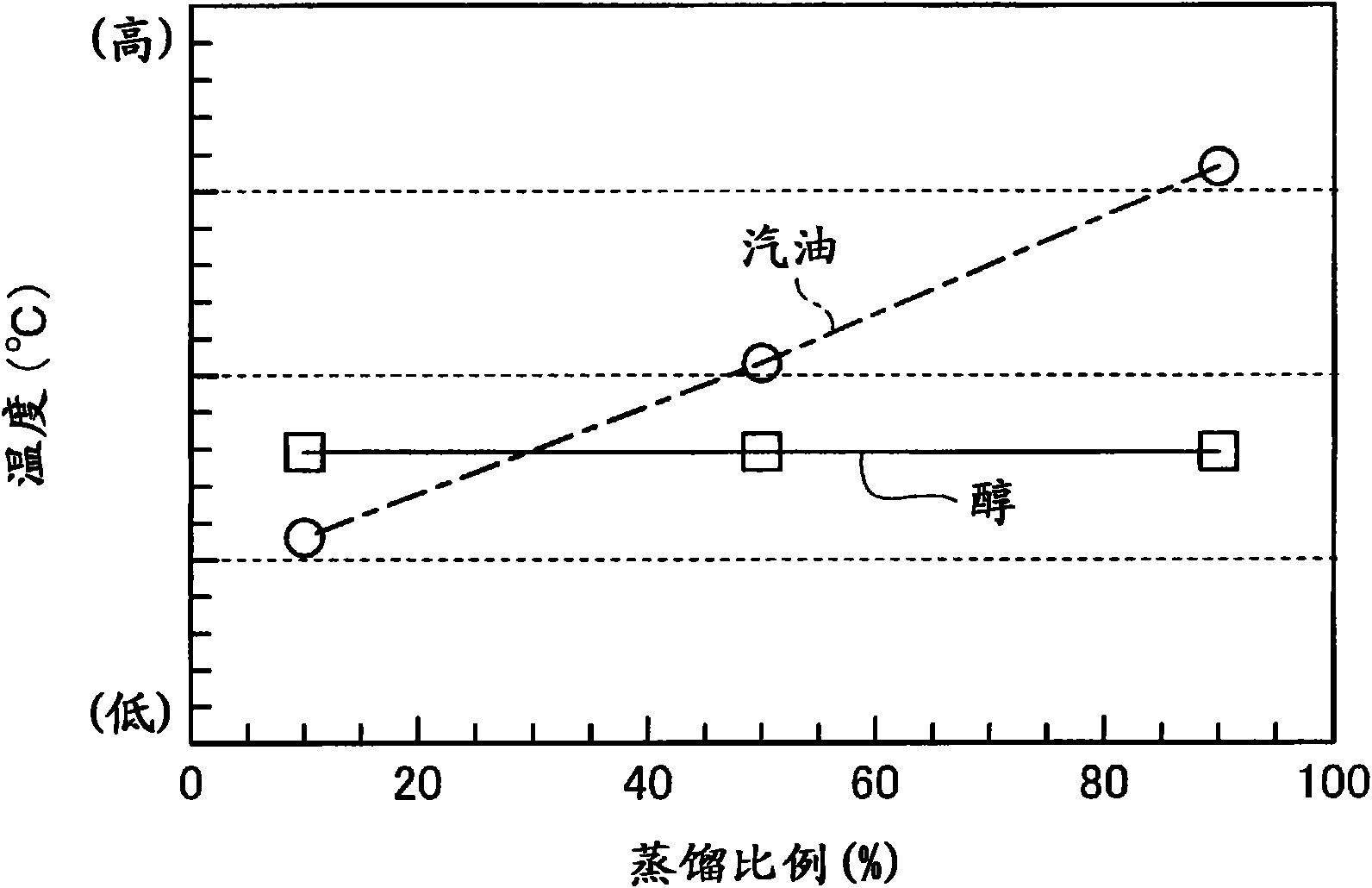

[0027] based on Figure 1 to Figure 3 Embodiment 1 of the multi-fuel internal combustion engine according to the present invention will be described. The multi-fuel internal combustion engine of Embodiment 1 refers to storing a single low-boiling point component fuel and at least one fuel mixture whose property state is different from the single low-boiling point component fuel in one fuel tank, and using the mixed fuel to operate internal combustion engine, through figure 1 The electronic control unit (ECU) 1 shown performs various control operations such as combustion control. The electronic control device 1 is composed of a CPU (Central Processing Unit) not shown, a ROM (Read Only Memory) in which predetermined control programs and the like are stored in advance, a RAM (Random Access Memory) in which temporarily stores calculation results of the CPU, and Consists of backup RAM, etc. to store pre-prepared information, etc. In addition, the single low-boiling-point compone...

Embodiment 2

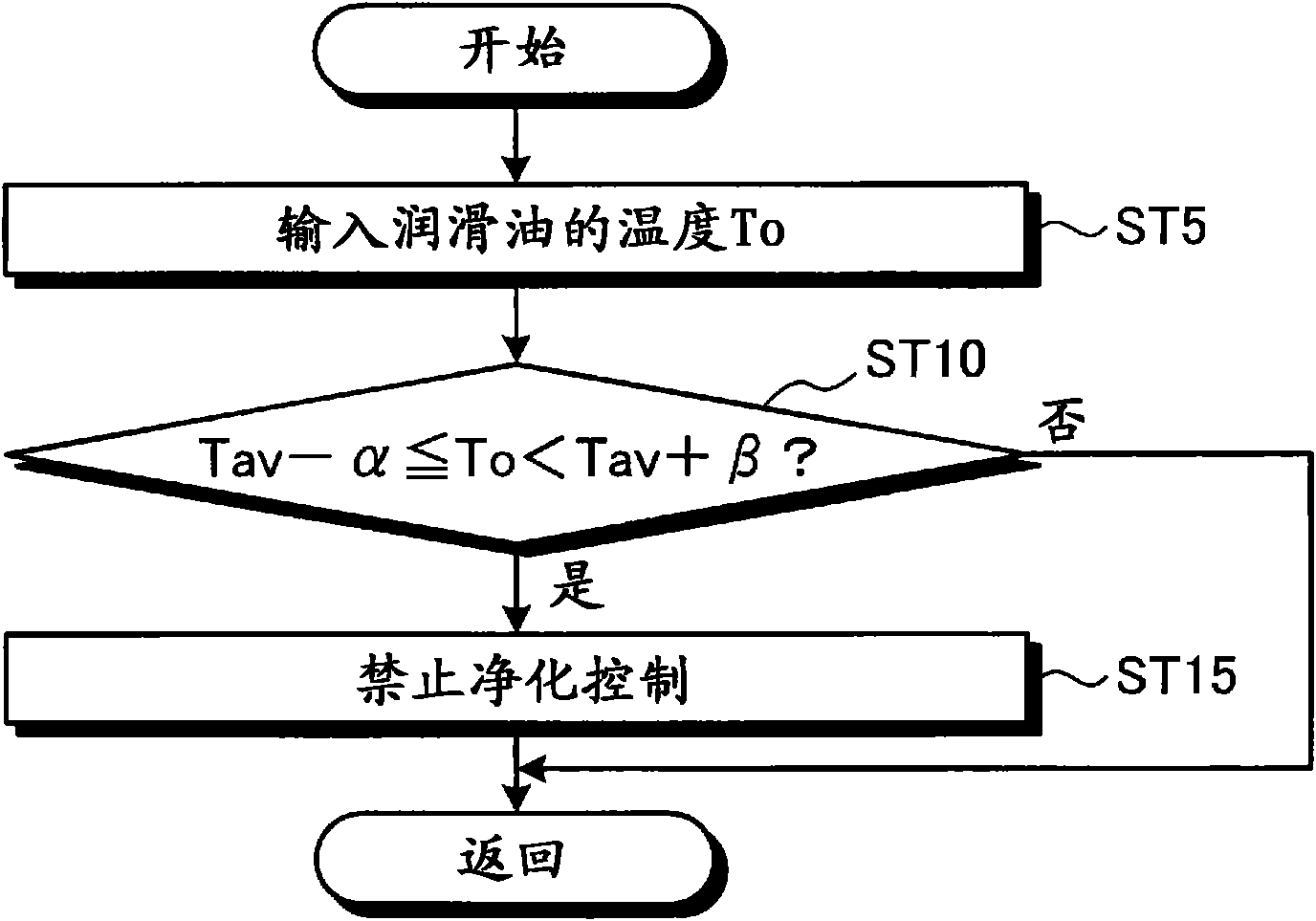

[0061] Below, based on figure 1 and Figure 4 Embodiment 2 of the multi-fuel internal combustion engine related to the present invention will be described.

[0062] In the multi-fuel internal combustion engine of the above-mentioned embodiment 1, if the temperature To of the lubricating oil in the oil pan 17 has entered the specified purification control prohibition temperature range (Tav-α≤To

[0063] However, the lubricating oil in the oil pan 17 is not always mixed with the same amount of alcohol fuel (single low-boiling point component fuel), and it is not ideal to completely prohibit purge control using only the temperature To of the lubricating oil. That is to say, when the amount of alcohol fuel mixed in the lubricating oil is small, the amount of alcohol fuel evaporated from the lubricating oil is also small, so when operating conditions that require a large amount of purge ...

Embodiment 3

[0080] Below, based on figure 1 , Figure 5 and Figure 6 Embodiment 3 of the multi-fuel internal combustion engine according to the present invention will be described.

[0081] The multi-fuel internal combustion engine of the present embodiment 3 is a modified example of the multi-fuel internal combustion engine of the above-mentioned embodiment 2, and the mixing amount of the single low-boiling point component fuel (alcohol fuel) into the lubricating oil in the oil pan 17 is also considered. Based on which to judge whether to prohibit the decontamination control.

[0082] Specifically, in the third embodiment, the configuration is as follows: instead of comparing the detected or estimated dilution rate Ro of lubricating oil with the predetermined value (predetermined dilution rate) Ra as in the second embodiment, The lubricating oil dilution ratio Ro is controlled by a purge control prohibition temperature range (Tav-α≤To<Tav+β) that is a threshold for judging whether pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com