Rapidly rotating vacuum pump

A vacuum pump, fast technology, applied in the direction of pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve problems such as large costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

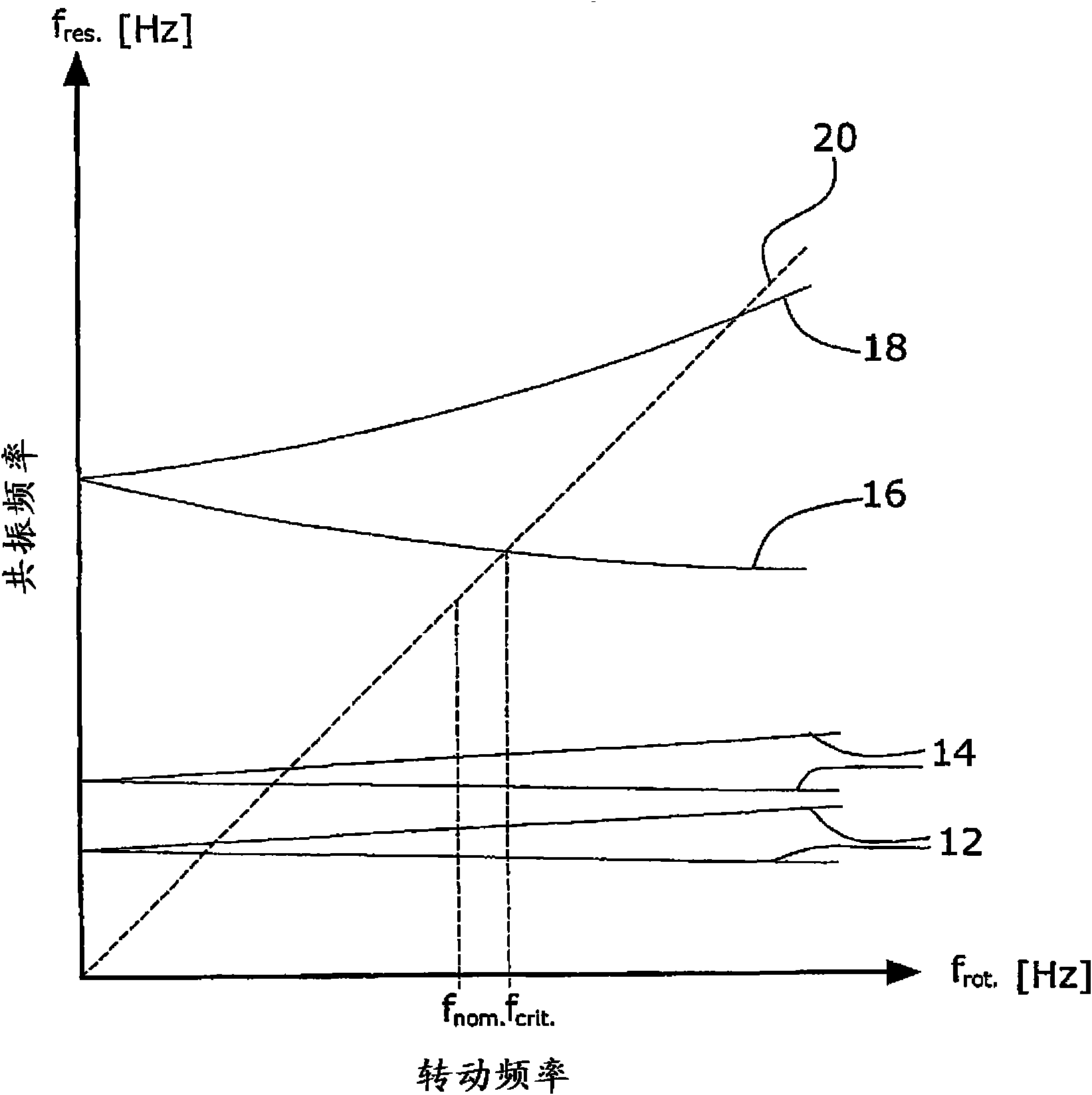

[0013] In the Campbell graph of the attached drawing, the rotation frequency f of the rotor is shown rot The resonance frequency of the rotor f res .

[0014] The rapidly rotating vacuum pump here is a turbomolecular vacuum pump, and the rotor of the turbomolecular vacuum pump is completely five-axis supported by magnetic bearings. The rotor is driven by an electric drive motor and has a constant fixed rated rotation frequency f nom Running.

[0015] In the graph, firstly, the critical resonance frequency curves 12 and 14 of the rigid body are shown two by one in the low speed range. These resonance frequencies vary with the rotation frequency f of the rotor rot Change to a relatively small degree. In addition, in the range of higher rotation speeds, the bending-critical reverse rotation resonance frequency curve 16 and the bending-critical co-rotation resonance frequency curve 18 are shown. In addition, a so-called position vector 20 is shown by a broken line. Where the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com